Car coupler disassembling method

A coupler and locomotive technology, which is applied in the direction of motor vehicles, vehicle scrap recycling, recycling technology, etc., can solve the problems of high cost of the mobile hydraulic system, large overall volume of the disassembly device, and complicated equipment coordination, and achieve saving of large-scale mobile hydraulic systems, Strong universality and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

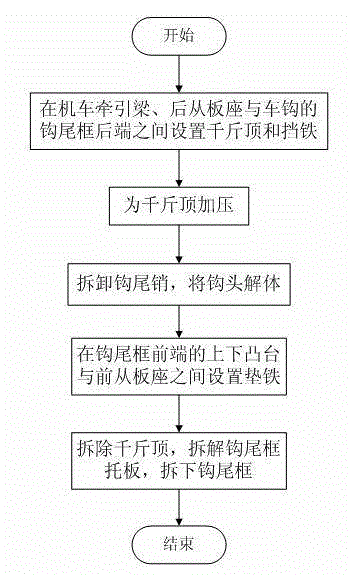

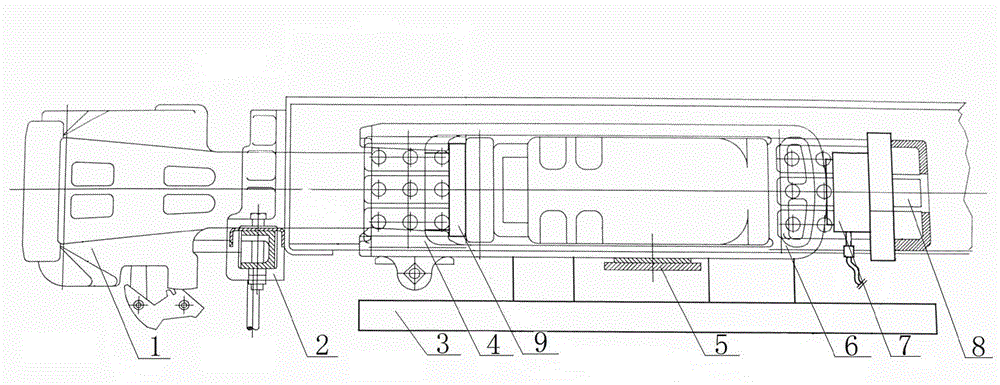

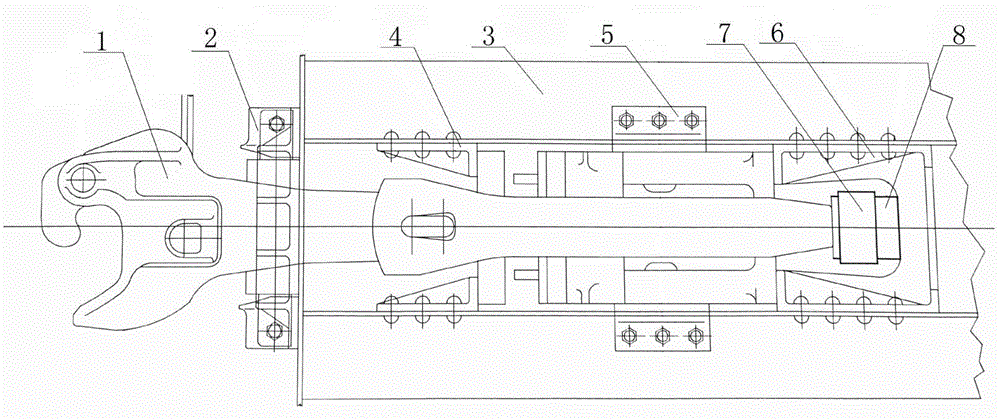

[0021] Depend on Figure 1 to Figure 3 The present invention is shown and described in detail in conjunction with specific practice.

[0022] Usually, the coupler frame, the buffer, and the front slave plate at the rear part of the coupler are integrally installed in the draw beam 3 at both ends of the vehicle body chassis, and the front slave plate and the buffer are clamped on the front slave plate seat 4 and the rear slave plate seat 4 of the draw beam 3. Between the plate bases 6, the bottom of the coupler frame is supported by the coupler frame supporting plate 5. In the process of disassembling the coupler, firstly, the coupler head 1 of the coupler should be separated from the coupler tail frame, and then the coupler tail frame should be disassembled from the draw beam 3, so that the whole coupler can be disassembled. In order to remove the coupler frame from the draw beam 3, it is necessary to ensure that the coupler frame can move between the front slave plate seat 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com