Discharge mechanism used for large-scale pretreatment device for municipal solid wastes, and waste pretreatment device

A municipal solid waste and pretreatment device technology, applied in the directions of packaging, transportation, packaging, containers, etc., can solve the problems that the bolt discharge device is easy to deform, it is difficult to realize large-scale promotion and application, and the production cost and operation cost are high. Conducive to the effects of intelligent control, superior drive mode, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

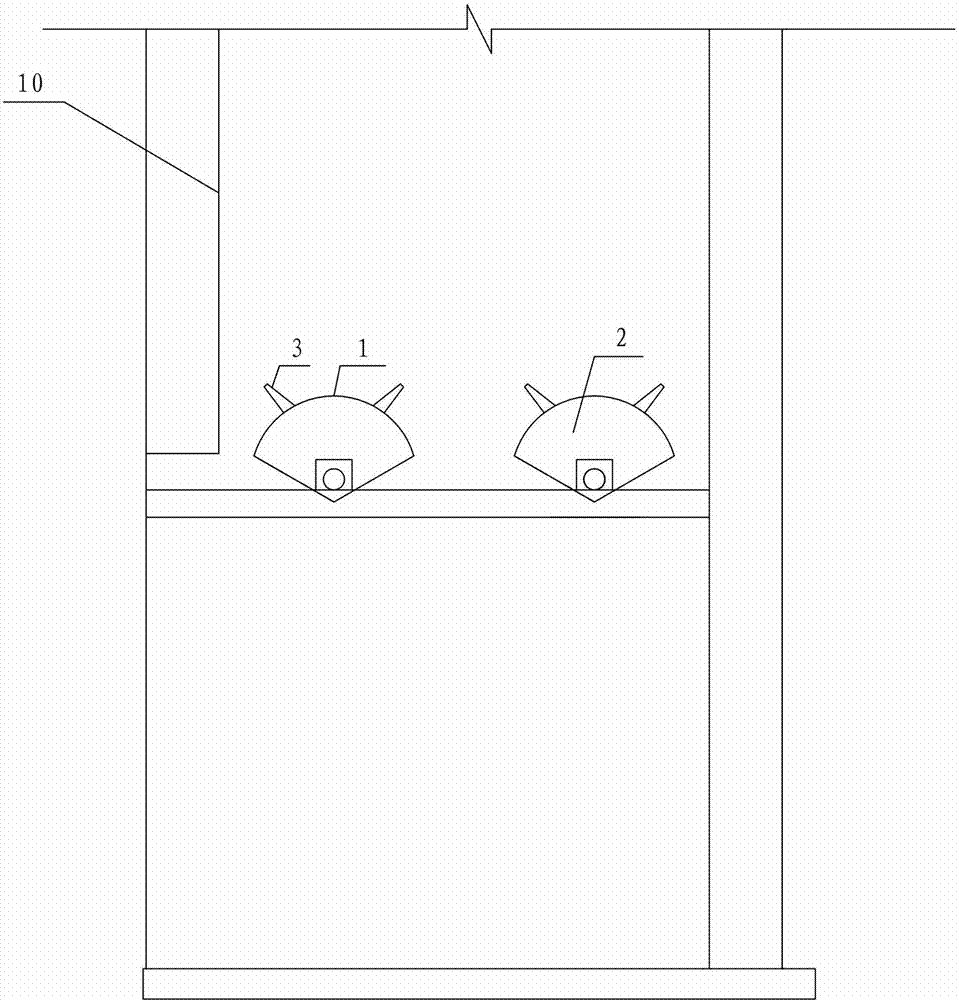

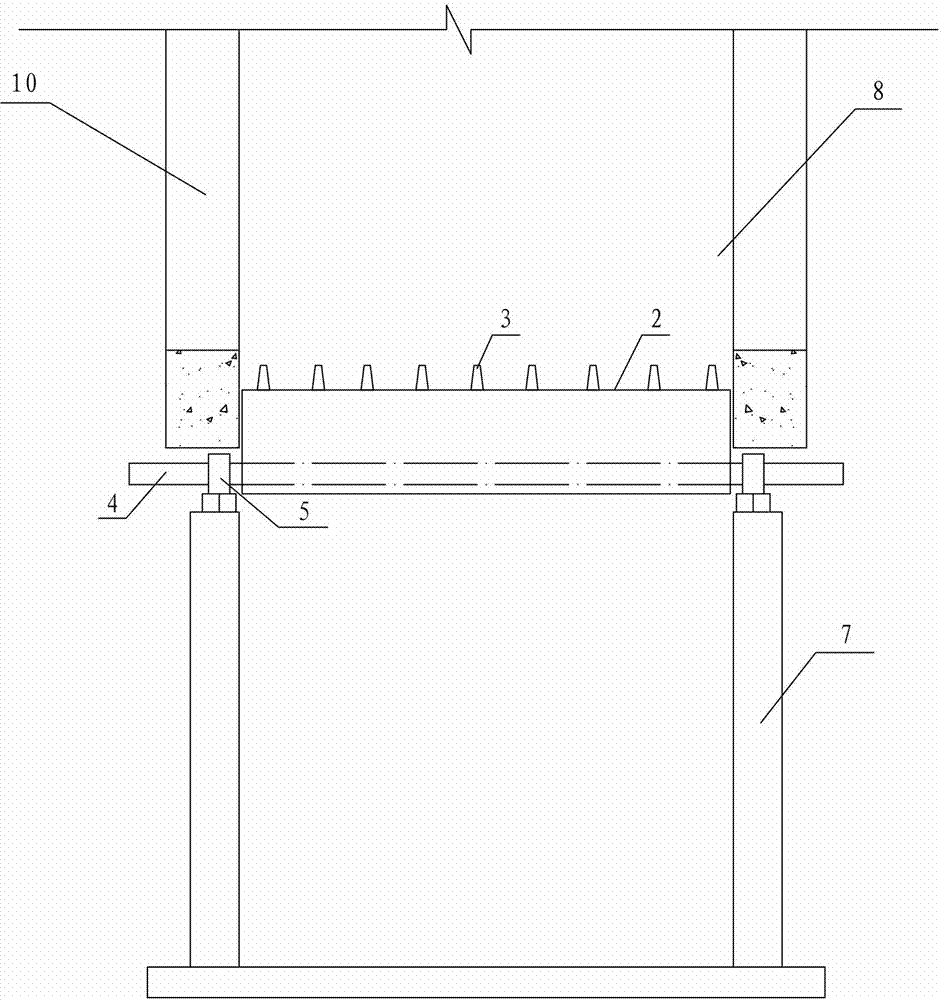

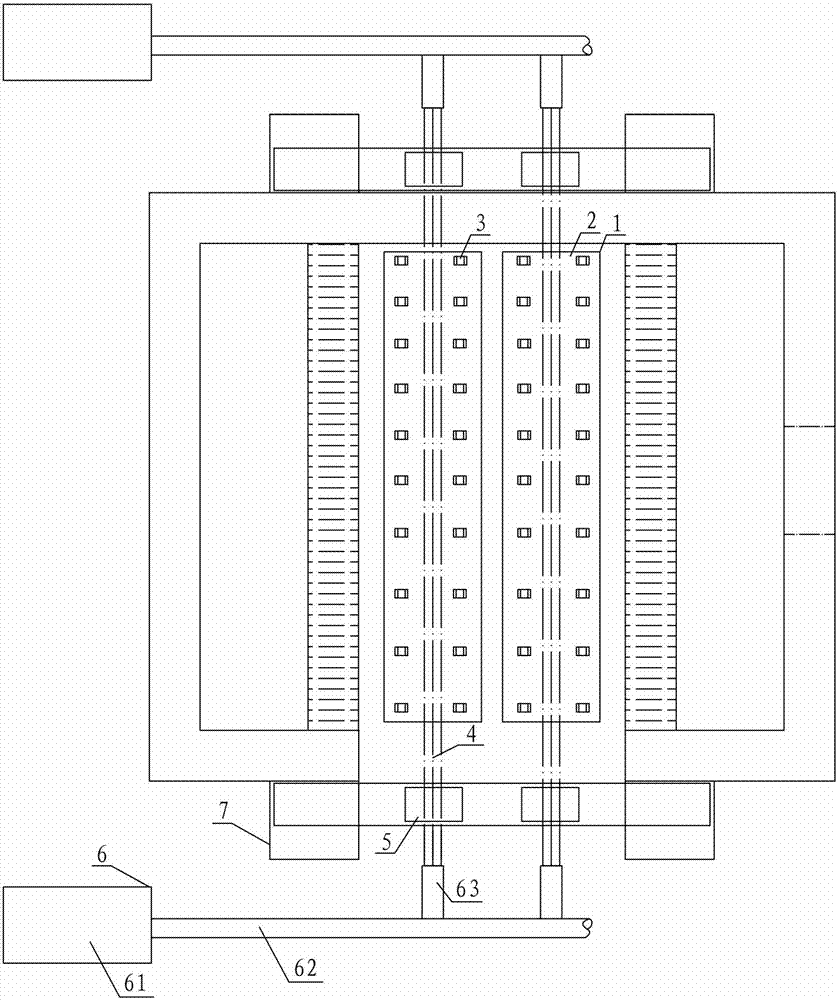

[0039] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

[0040] Through long-term practical research, it is found that in order to realize the smooth discharge of waste, it is necessary to analyze the mechanical properties of waste. Generally speaking, the mechanical properties of garbage are:

[0041] 1. Garbage contains fiber components (paper, plastic, fabric, rope, iron wire, etc.), which makes it difficult to separate the garbage.

[0042] 2. Garbage contains a large amount of organic matter that can be decomposed by microorganisms and physical, chemical, and biodegradable components, resulting in a reduction in the volume of garbage.

[0043] 3. Garbage has obvious strain hardening law during and after fermentation. That is, the shear resistance increases with the increase of strain or shear displacement.

[0044] 4. Due to the law of strain hardening during and after fermentation of ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com