Spiral tubular discharging unit for ozone generator

A technology for ozone generators and discharge units, applied in the field of ozone generators, can solve the problems of small discharge specific surface area of ozone generators, large footprint of large-scale equipment, high installation and maintenance costs, and reduce equipment investment and maintenance costs. Increased ozone production and concentration, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

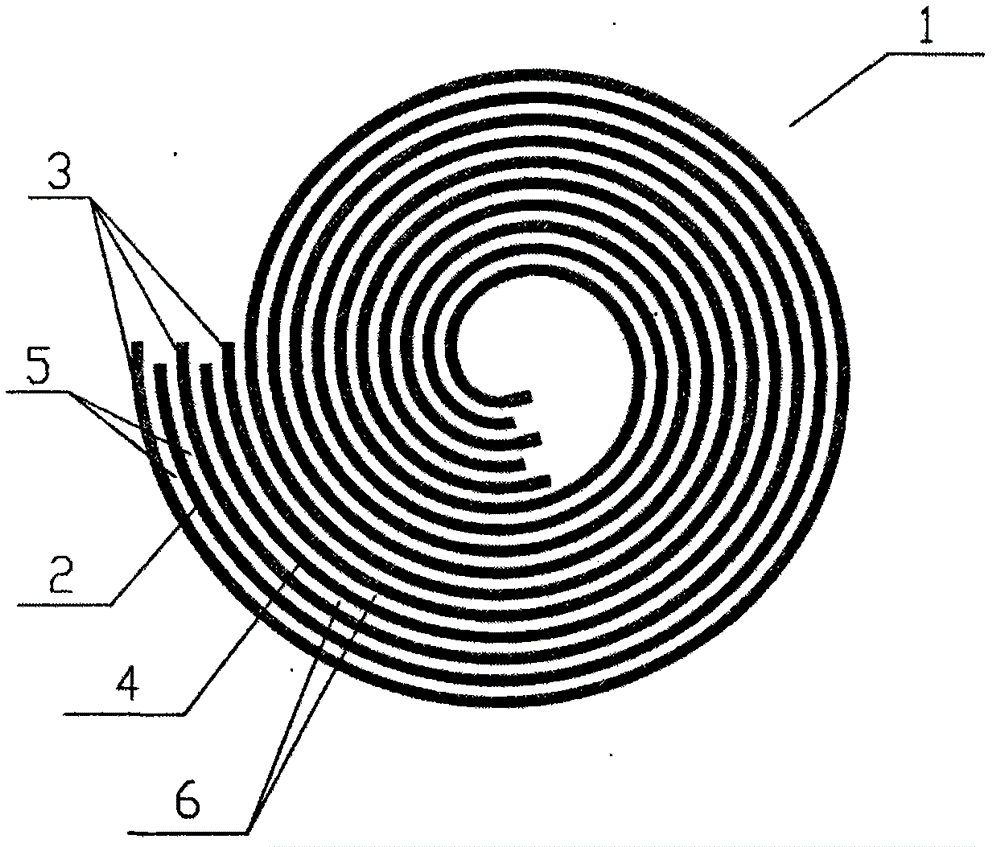

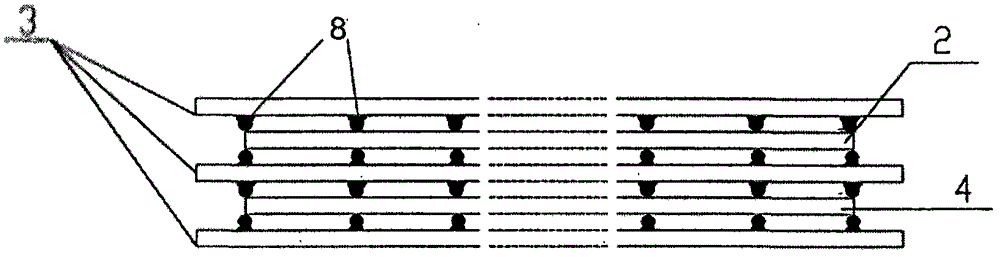

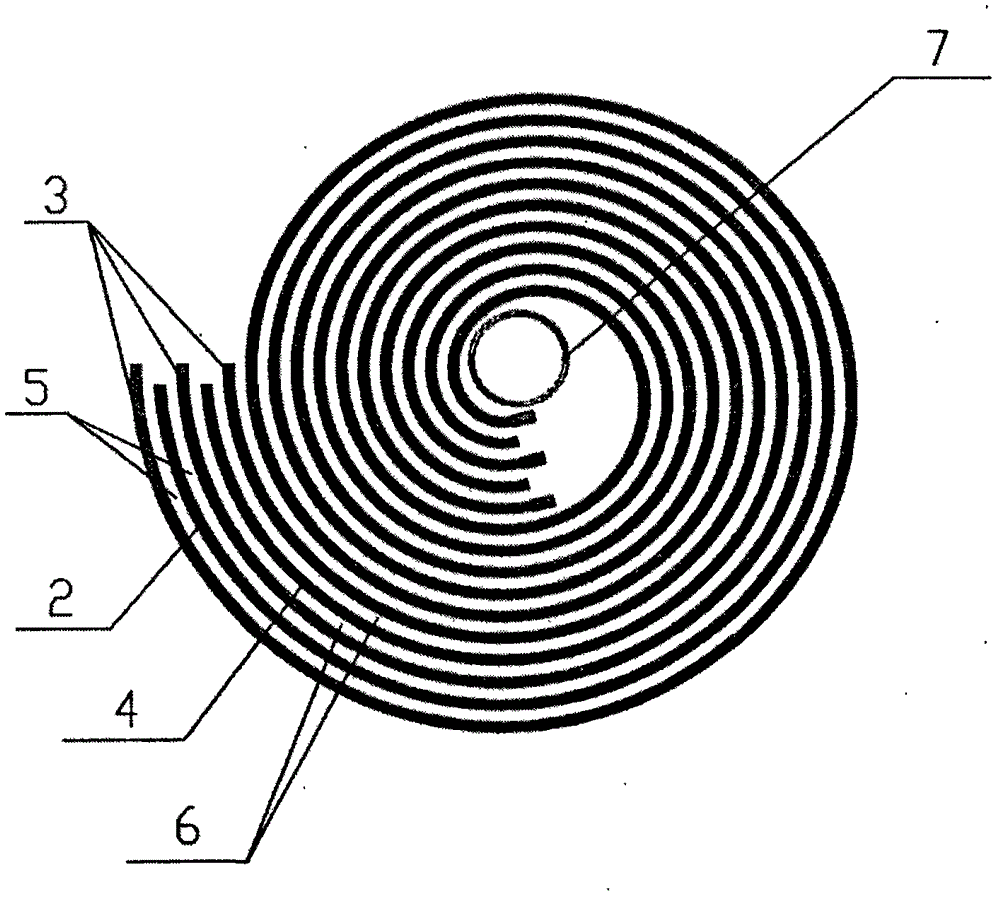

[0033] The following is attached Figure 1-3 Two embodiments of the present invention are described in detail.

[0034] Such as figure 1 As shown, the purpose of the present invention provides a spiral tubular discharge unit 1 for an ozone generator, consisting of a group of not less than one sheet-shaped and rollable ground electrode 2, an insulating layer 3 and a high-voltage electrode 4 overlapping each other And the whole is rolled into a spiral cylinder shape along one edge thereof, the high-voltage electrode 4 and the ground electrode 2 are separated by an insulating layer 3, and one or both surfaces of the insulating layer 3 are simultaneously provided with protrusions 8. The edge of the insulating layer 3 exceeds the edge of the ground electrode 2 and the high voltage electrode 4 , and there are discharge gaps between the ground electrode 2 and the insulating layer 3 and between the insulating layer 3 and the high voltage electrode 4 . Preferably, the size of the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com