Preparation method of high-temperature resistant modification polyisocyanurate foamed plastic

A technology of polyisocyanurate and foamed plastics, which is applied in the field of preparation of foamed plastics and modified polyisocyanurate foamed plastics, can solve problems such as difficult processing and brittle products, and improve high temperature resistance , Improve the effect of flame retardancy and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

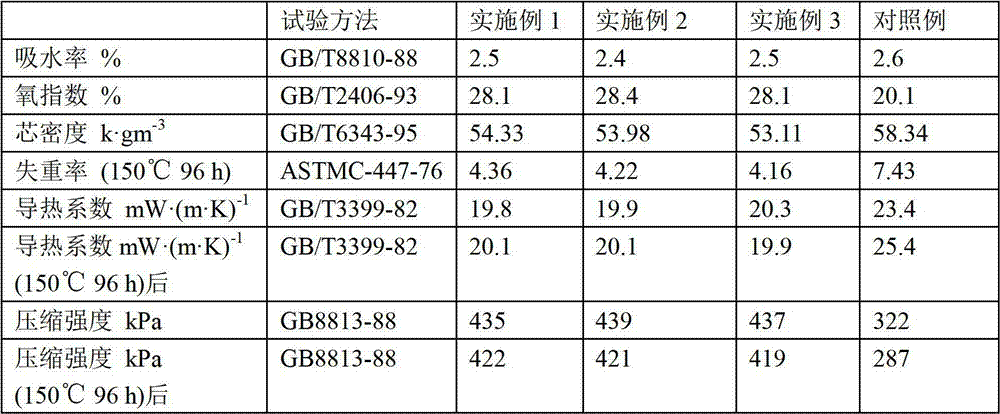

Examples

Embodiment Construction

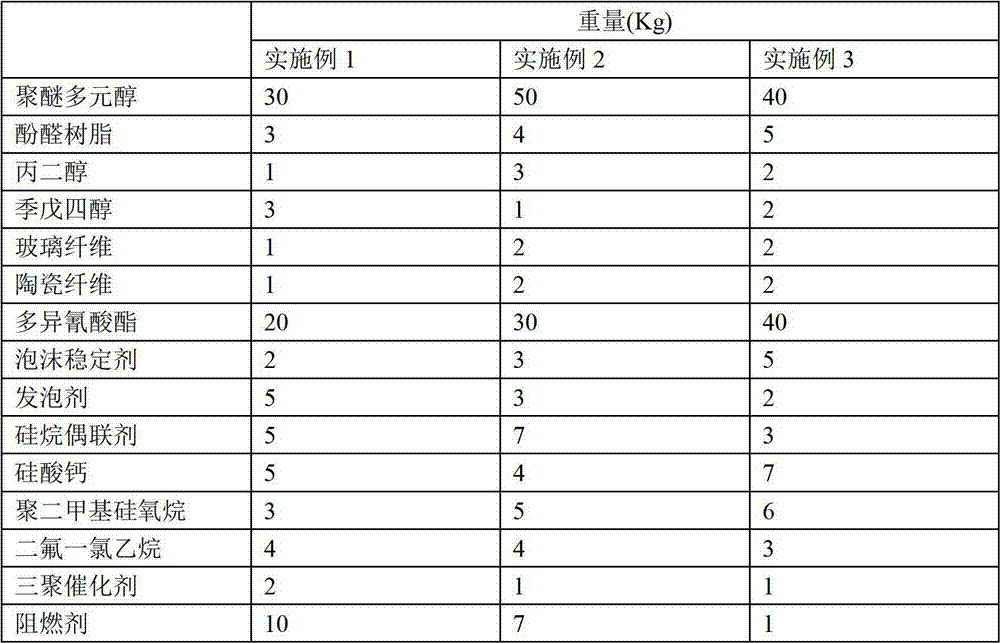

[0020] The weight proportion of table 1 embodiment 1~embodiment 3

[0021]

[0022] The above-mentioned polyether polyol is polyether polyol 403, and its hydroxyl value is 300KOH / g.

[0023] The aforementioned foam stabilizer is silicone oil.

[0024] The blowing agent mentioned above is cyclopentane.

[0025] The trimerization catalyst mentioned above is potassium isooctanoate.

[0026] The polyisocyanate mentioned above is a diisocyanate with a functionality of 2.10.

[0027] The aforementioned catalyst is tetramethylethylenediamine.

[0028] The above-mentioned phosphate ester flame retardant is triisobutyl phosphate.

[0029] The preparation method is:

[0030] S1: Polyether polyol, phenolic resin, propylene glycol, pentaerythritol, glass fiber, ceramic fiber, foam stabilizer, foaming agent, silane coupling agent, calcium silicate, polydimethylsiloxane, difluorochloro Ethane, trimerization catalyst and flame retardant are mixed evenly in a certain proportion;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap