Bi-stable three-way valve

A three-way valve and bistable technology, applied in the field of three-way valve, can solve the problems of power consumption, unsafe and reliable, high manufacturing cost, and achieve the effects of energy saving, stable work, safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

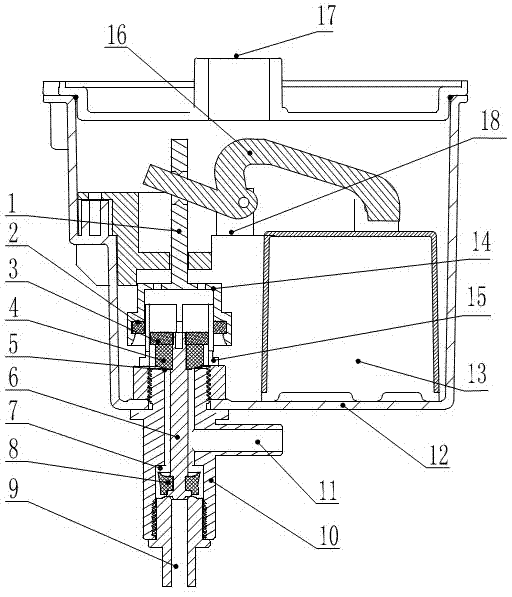

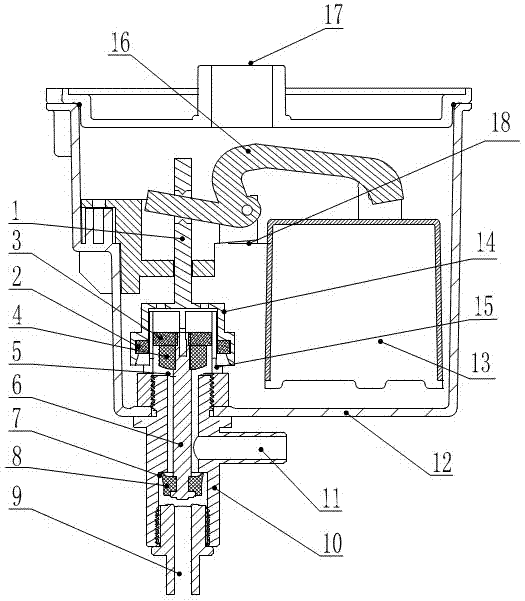

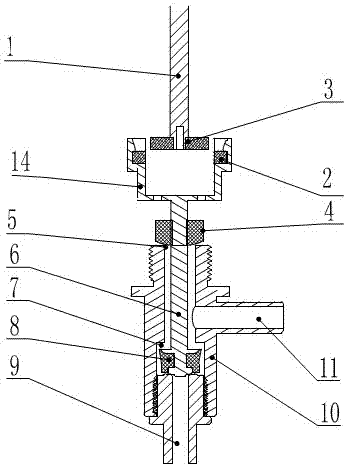

[0013] The structure and working state of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as Figure 1~2 As shown, the float 13 located in the water tank 12 and the magnetic ring assembly located on one side of the float 13, the three-way valve body 10 that is located under the magnetic ring assembly and communicates with the water tank 12, and the three-way valve body 10 that is located in the three-way valve body 10 The three-way valve core 6, the upper and lower ends of the three-way valve core 6 are nested with the upper valve plug 4 and the lower valve plug 8, and the side wall of the three-way valve body 10 is provided with a water outlet 11, an upper water inlet 5 and a lower water inlet 7, and the three-way The upper end of the valve core 6 and the upper valve plug 4 are fixedly connected with the lower end of the inner magnetic ring 3 of the magnetic ring assembly. The outer magnetic ring 2 of the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com