Fixing method for phase insulation of motor winding ends for refrigeration compressors

A technology of refrigeration compressor and fixing method, which is applied in laying solid insulation and other directions, can solve the problems of insufficient delivery of phase insulation, slippage or displacement, motor burnout, etc., and achieves the effects of convenient operation, realization of fixing, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

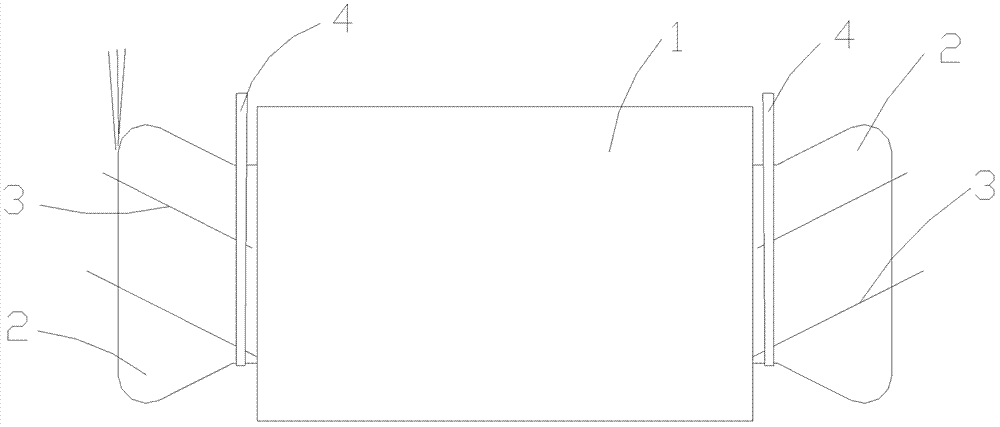

[0014] The technical scheme of the present invention will be further explained below in conjunction with the drawings.

[0015] See figure 1 As shown, a method for fixing the phase insulation of the winding ends of a motor for a refrigeration compressor, the fixing method mainly includes the following steps:

[0016] First, insert the phase insulation 3 between the phases of the winding 2 and insert it into the root of the winding 2, and then wind the binding tape 4 with good insulation performance around the root of the winding 2 along its outer circumference several times. And press the phase insulation 3 under the binding band 4. The binding tape 4 can be one or more of polyester fiber tape, electrical non-alkali glass fiber tape or polyester non-woven fabric tape. In order to prevent the phase insulation 3 from slipping or displacement due to mechanical vibration and other reasons after the binding tape 4 is tied, the phase insulation 3 is pulled out a certain length to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com