Quick joint valve assembly with interlocking device

A valve assembly and interlocking technology, used in mechanical equipment, couplings, etc., can solve the problems of casualties, disconnection, economic losses, etc., and achieve the effects of reliable performance, convenient operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

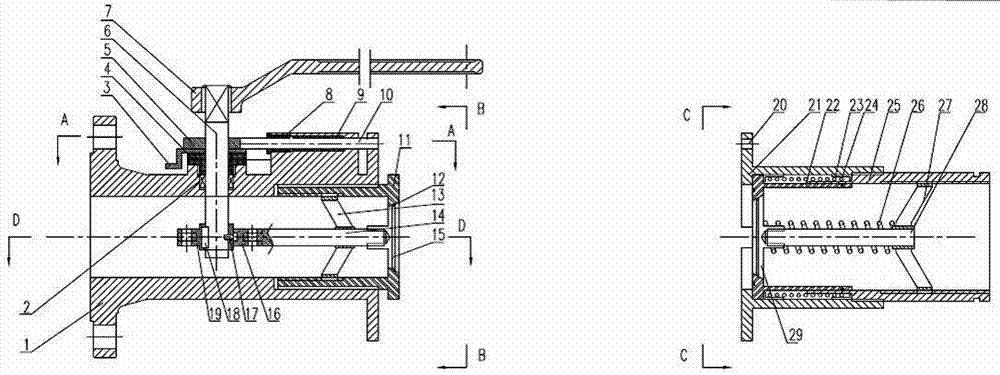

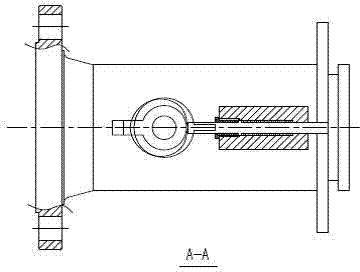

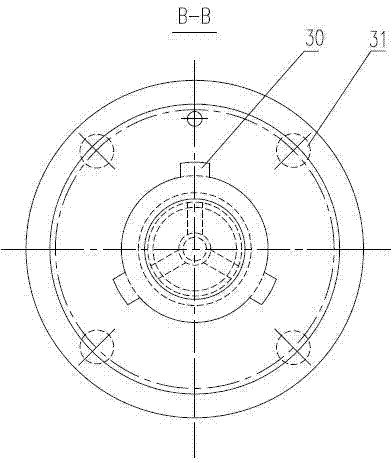

[0014] Such as figure 1 As shown, the male joint assembly includes connecting body A1, sealing packing 2, valve limit stopper 3, compression bolt 4, cam 5, valve stem 6, handle 7, spring compression bolt 8, lock core return spring 9, lock Core rod 10, male joint 11, seal ring 12, support ring guide sleeve 13, slide rod 14, male joint valve core 15, connecting rod 16, fixing screw 17, transmission connecting pin 18, crank 19; the female joint assembly includes a lock hole 20. Female joint 21, sleeve 22, spring sleeve 23, sleeve return spring A24, connecting body B25, self-closing spool spring 26, support ring sleeve 27, slide rod 28, self-closing spool 29.

[0015] The above connecting body A1 is tubular, and one end of the connecting body A1 has a built-in male joint 11, such as figure 1 , 2 As shown, the inner end of the male joint 11 is threadedly connected to the inner wall of the connecting body A1, and the outer end surface of the male joint 11 protrudes from the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com