Vibrating micro mechanical electric field sensor

An electric field sensor, micro-machine technology, applied in the direction of electrostatic field measurement, etc., can solve problems such as no error and compensation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

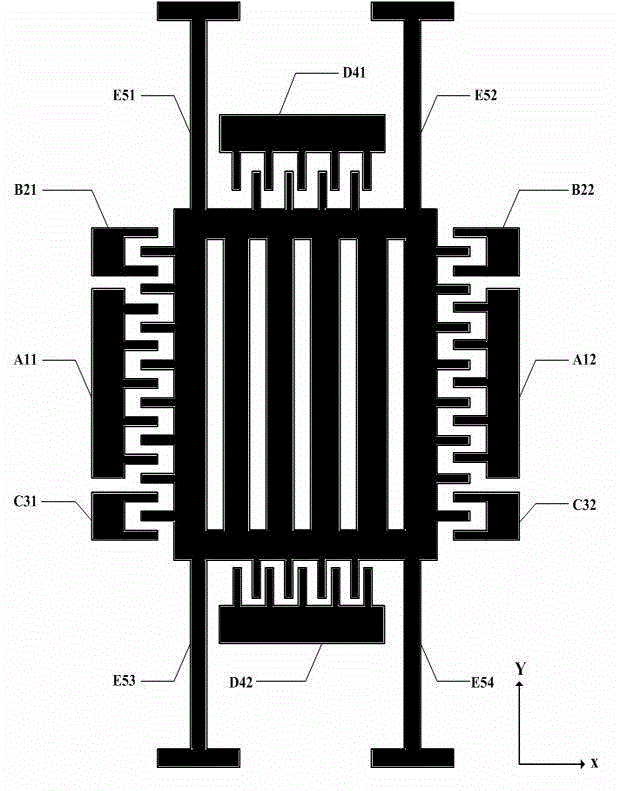

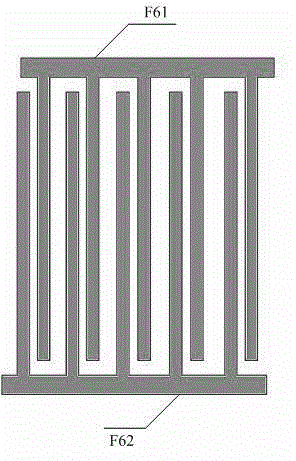

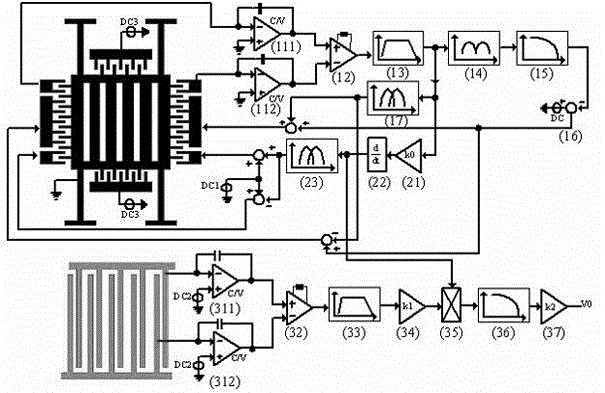

[0044] Such as figure 1 As shown, the vibrating micromechanical electric field sensor of the present invention includes a shielding layer 1 , a sensitive layer 2 and a base 3 . The sensitive layer 2 is made of monocrystalline silicon material through deep etching of bulk silicon to form a designed structure, the sensitive electrode is made of metal platinum material through sputtering, and the base 3 is made of glass material specially used for bonding. In order to make the movable structure have a movable space, there is a certain space between the sensitive electrode layer and the shielding structure layer, and the shielding layer structure and the base are combined through anodic bonding.

[0045] Such as figure 2 As shown, the shielding layer 1 includes a movable structure E5 and a fixed comb structure, wherein the movable structure E5 includes a rectangular mass block with a gap in the center, comb teeth arranged around the mass block, and four corners connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com