All-solid-state power storage device

An all-solid-state, energy storage technology, applied to fixed capacitors, fixed capacitor parts, capacitors, etc., can solve the problems of low energy density and low power density, and achieve high energy density, short charging time, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

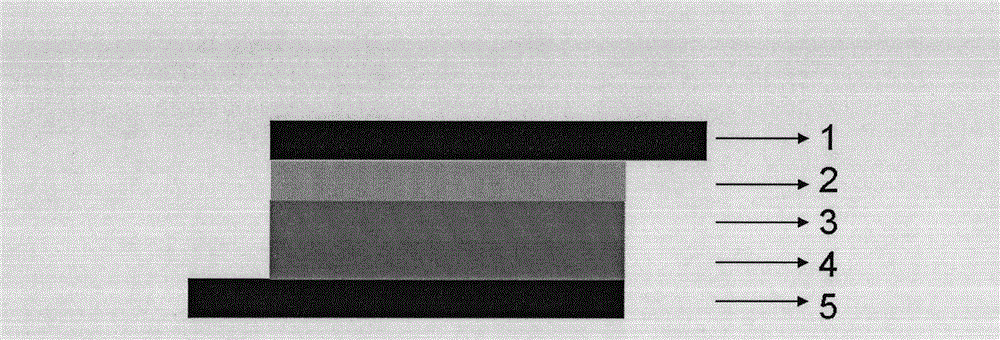

[0021] Prepare a layer with an area of 10×10cm on the surface of metal aluminum by vacuum evaporation technology 2 , 3,3'-dimethyl-5,5'-di-tert-butyldiphenoquinone with a thickness of 1 μm, and then spin-coat a layer of polyimide with a thickness of 5 μm on the surface of the diphenoquinone layer. Finally, a layer of polyvinylcarbazole polymer (average molecular weight: 19325) with a thickness of 750 nm was spin-coated on the polyimide surface. After drying and solidification, a layer of 100 nm metal aluminum is vacuum-evaporated on the surface of the polymer to obtain the all-solid-state energy storage device of the present invention. Tests show that the all-solid-state energy storage device can be charged within 1.5 minutes, with an energy density of 500Wh / kg and a power density of 8.7kW / kg.

Embodiment 2

[0023] Vacuum evaporation technology is used to sequentially evaporate the area of 10×10cm on the glass surface 2 , a thickness of 100nm metal copper, a thickness of 500nm diphenoquinone (3,3'-dimethyl-5,5'-di-tert-butyl diphenoquinone and 3,5-dimethyl-3',5 A mixture of '-di-tert-butyldiphenoquinone, the mass ratio is 1:1), SiO with a thickness of 200nm 2 . Then a layer of poly(p-phenylene vinylene) (average molecular weight 8050) with a thickness of 380 nm was spin-coated on the surface. After drying and curing, a layer of metal copper with a thickness of 100 nm is vacuum evaporated on the surface of the polymer to obtain the all-solid-state energy storage device of the present invention. Tests show that the all-solid-state energy storage device can be charged within 1 minute, with an energy density of 536Wh / kg and a power density of 9.4kW / kg.

Embodiment 3

[0025] Prepare a layer with an area of 10×10cm on the surface of metal aluminum by vacuum evaporation technology 2 , 3,3'-dimethyl-5,5'-di-tert-butyldiphenoquinone with a thickness of 2 μm, and then spin-coat a layer of polydimethylsiloxane with a thickness of 5 μm on the surface of the diphenoquinone layer. Finally, a layer of polyvinylcarbazole polymer (average molecular weight: 1930) with a thickness of 1.8 μm was spin-coated on the surface of the polydimethylsiloxane layer. After drying and curing, a layer of metal aluminum with a thickness of 100 nm is vacuum deposited on the surface of the polymer to obtain the all-solid-state energy storage device of the present invention. Tests show that the all-solid-state energy storage device can be charged within 3.5 minutes, with an energy density of 483Wh / kg and a power density of 8.2kW / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com