Method for controlling temperature of super-huge coke oven

A control method and super-large technology, applied in the heating of coke ovens, coke ovens, combustible gas heating coke ovens, etc., to achieve the effects of lower furnace top space temperature, significant benefits, and improved maturity uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

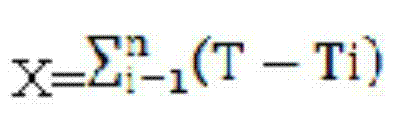

[0043] Using computer to write relevant programs, the main method is to carry out statistics and data processing through the difference between the coal charging time and the current time in the database of Maanshan Iron and Steel's 7.63m coke oven.

[0044] The processed data is stored in the database and provided for other control programs to call. And provide standard ODBC interface.

[0045] This design was successfully applied in the 7.63m coke oven of Maanshan Iron and Steel Co., Ltd.

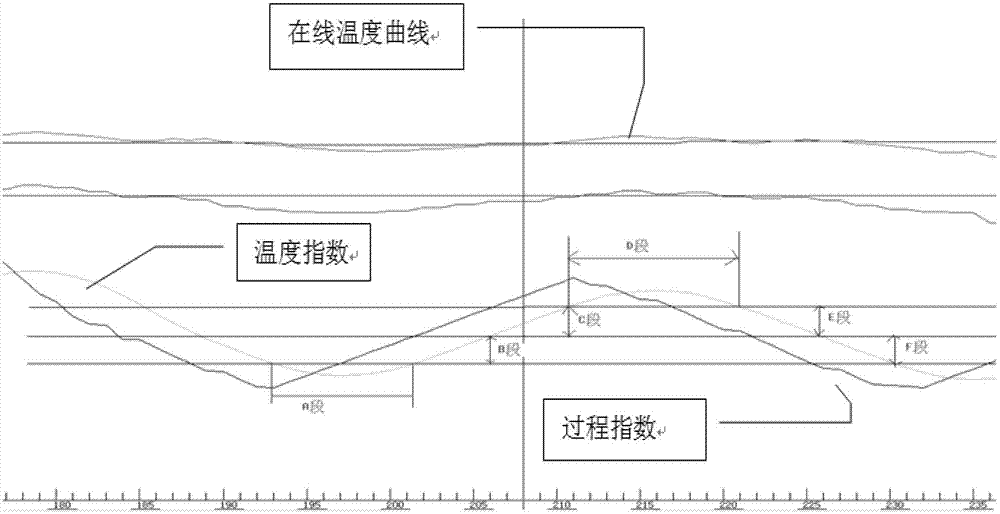

[0046] The programming software imports the production process index and temperature index data of the 7.63m coke oven through the ODBC interface.

[0047] At the same time, read the re-collection temperature, and compare the two sets of data with the set value to obtain the adjustment seconds;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com