sewing machine

A sewing machine and motor technology, applied in sewing machine components, sewing machines, sewing machine control devices, etc., can solve the problems of loss of component replacement and lack of versatility, and achieve the goal of suppressing axial size, improving versatility, and ensuring durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

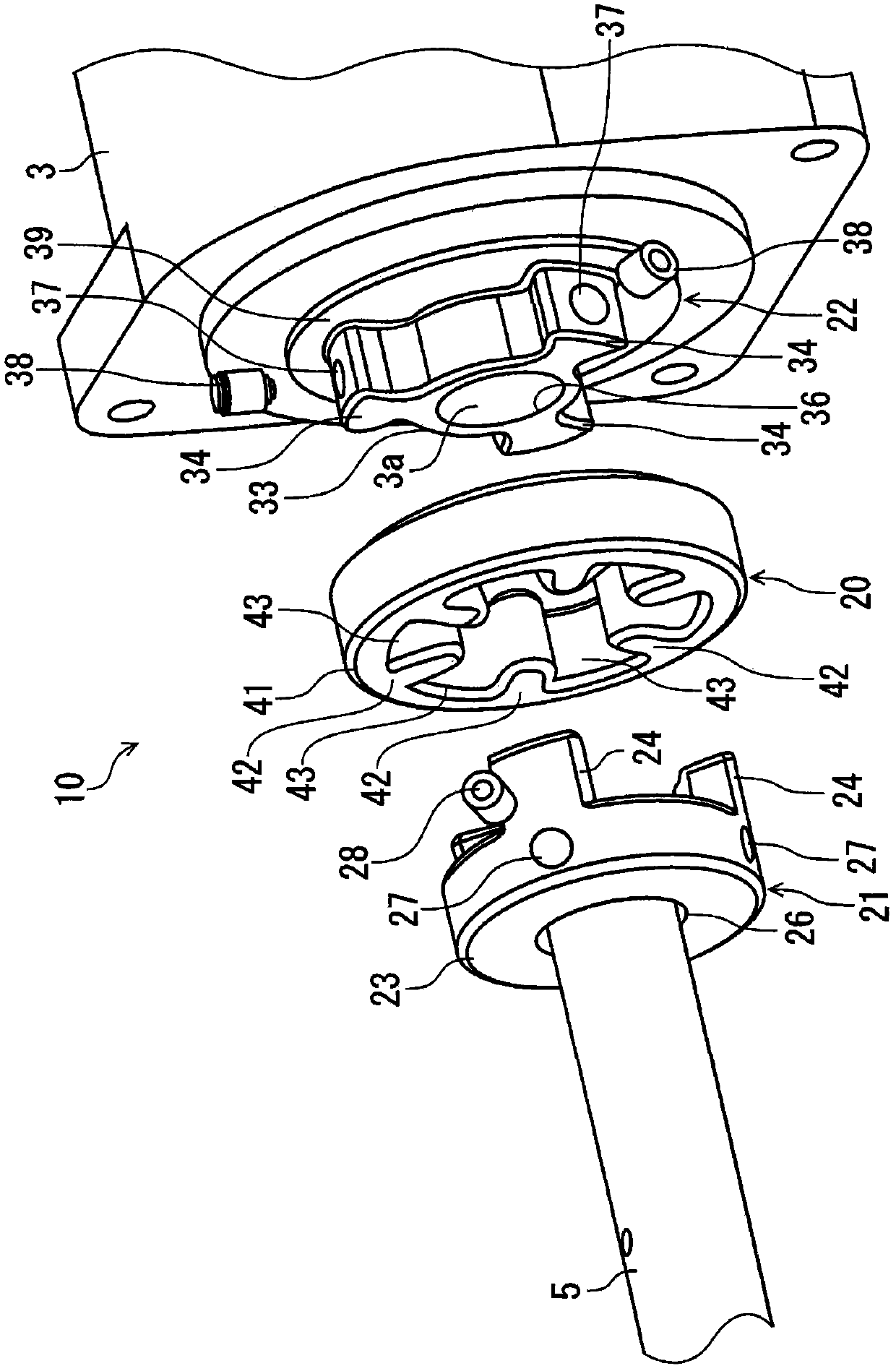

[0044] Below, refer to Figure 1 to Figure 5 , and the first embodiment of the present invention will be described.

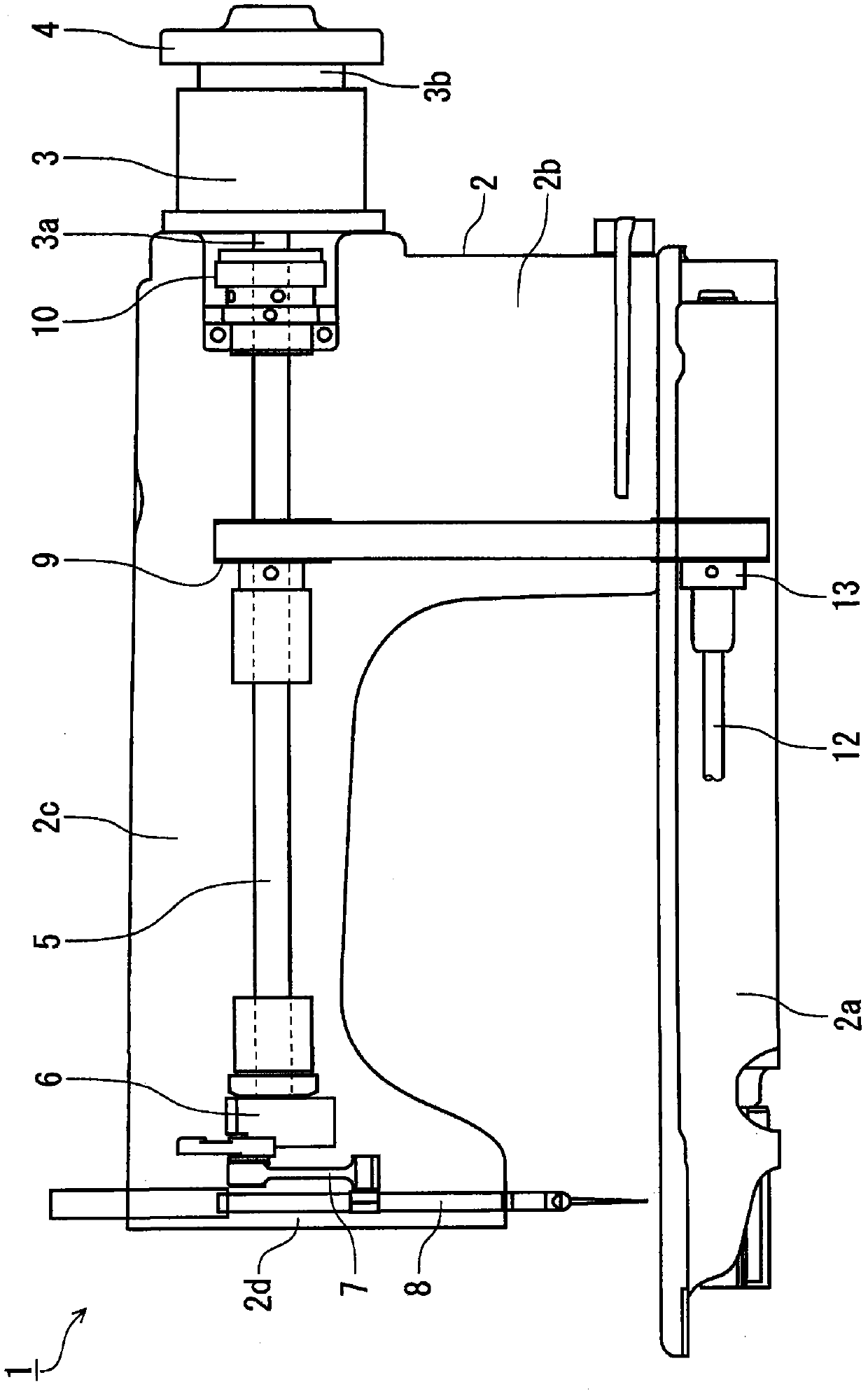

[0045] Such as figure 1As shown, the sewing machine 1 has a sewing machine frame 2 . The sewing machine frame 2 has: a base portion 2a; a vertical body portion 2b, which is erected on the base portion 2a; an arm portion 2c, which is disposed substantially parallel to the base portion 2a from the upper portion of the vertical body portion 2b; and a head portion 2d, which It is arranged at the front end of the arm portion 2c.

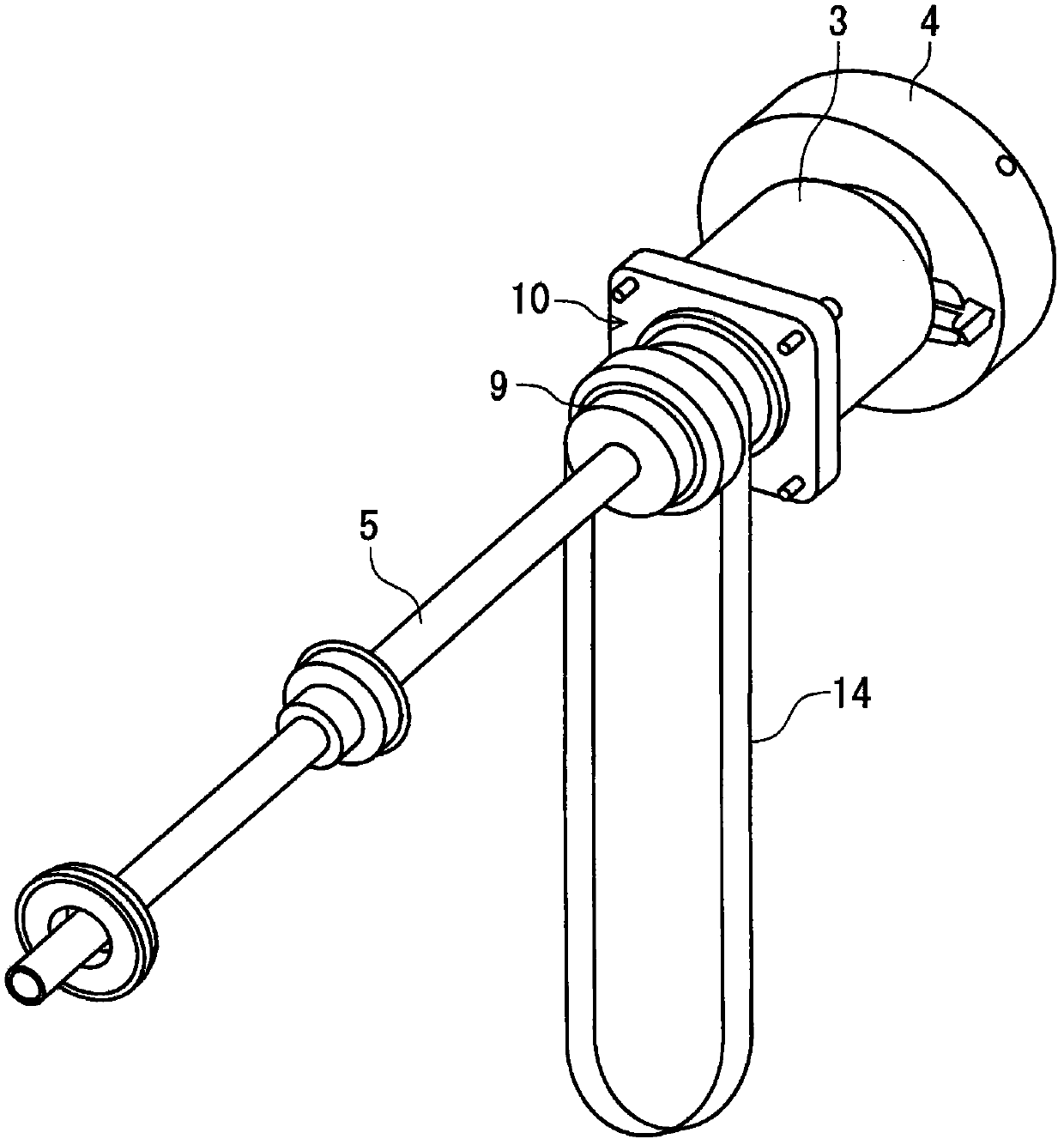

[0046] The electric motor 3 is disposed outside the upper portion of the vertical body portion 2b. The motor 3 has a pair of rotating shafts 3a, 3b protruding from both sides in the axial direction. The rotating shaft 3 a is connected to the upper shaft 5 , and the rotating shaft 3 b is connected to the flywheel 4 . The flywheel 4 is disposed outside the longitudinal body portion 2b. The outer periphery of the motor 3 is covered by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com