Processing method for removing hydrolyzed reactive dyes on cotton knitted fabric by using solvent water system

A technology of hydrolysis activity and processing method, which is applied in the direction of textiles, papermaking, and dry-cleaning fiber products. It can solve the problems of reducing water consumption and increasing energy use, and achieves the effects of reducing sewage discharge, saving energy consumption, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

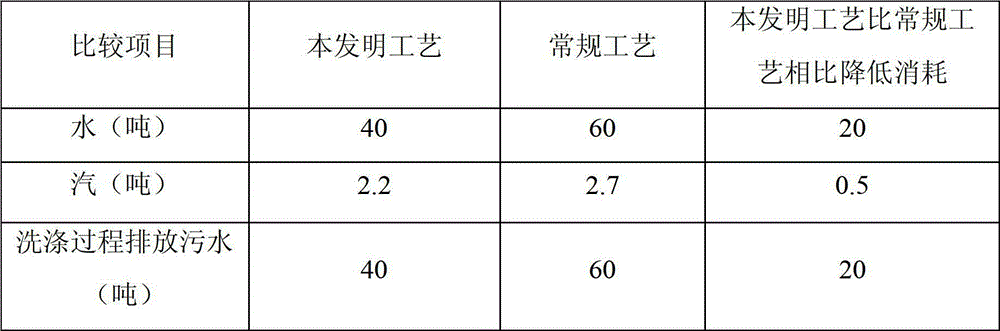

Embodiment 1

[0023] 1. Pretreatment of dyed fabric: After dyeing the cotton fabric, drain the dyeing residue, wash it twice with water at room temperature (water-to-bath ratio 1:10, time 10 minutes), and soap it once (the amount of Shanghai Jiahe soaping agent AST is 1g / l, temperature 95°C, time 20min, bath ratio 1:10); 2. Preparation of acetone water system: under normal temperature conditions, add acetone and water in a volume ratio of 1:1 into the sealing treatment equipment equipped with fabrics , the bath ratio is controlled at 1:10, and the pH is adjusted to 8±0.1 with soda ash; 3. The acetone water system is used to treat the cotton fabric: the acetone water system is heated to 40°C, and after the cotton fabric is treated for 20 minutes, the residual liquid is discharged into the solvent In the recovery equipment, then add the acetone water system in the same way, treat at 40°C for 20 minutes, and discharge the residual liquid into the recovery equipment; 4. Acetone recovery.

[002...

Embodiment 2

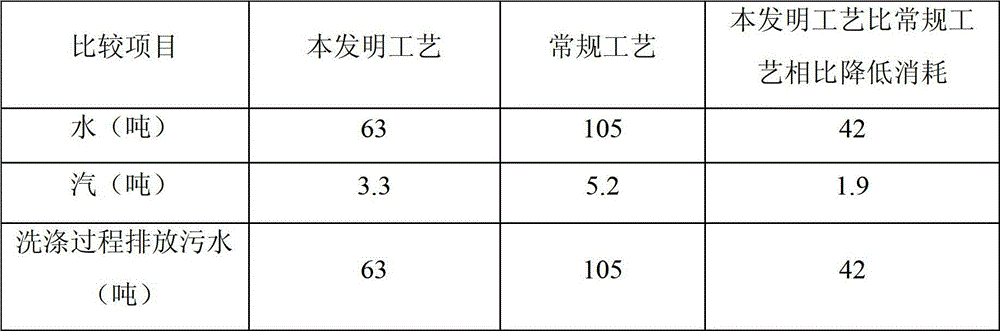

[0027] 1. Soaping of dyed fabrics: Drain the dyed fabrics, drain the dyeing residue, wash them twice at room temperature (water bath ratio 1:15, time 10min), soaping (Shanghai Jiahe AST soaping agent dosage is 2g / l, temperature 95°C, time 20 minutes, bath ratio 1:15); 2. Preparation of solvent water system: under normal temperature conditions, add the sealing treatment equipment equipped with fabric according to the ratio of absolute ethanol to water 1:1.5 In the process, the bath ratio is controlled at 1:15, and the pH is adjusted to 6±0.1 with glacial acetic acid; 3. Treatment of cotton fabrics in the absolute ethanol water system: raise the temperature of the absolute ethanol water system to 50°C, and treat the cotton fabrics for 30 minutes , the residual liquid is discharged into the solvent recovery equipment, and then added to the absolute ethanol water system according to the same method, treated at 50°C for 30 minutes, and the residual liquid is discharged into the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com