Test method capable of realizing vibration characteristics physical separation of stator and rotor

A technology of physical separation and rotor vibration, applied in vibration testing, testing of machine/structural components, measuring devices, etc., to achieve the effect of decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

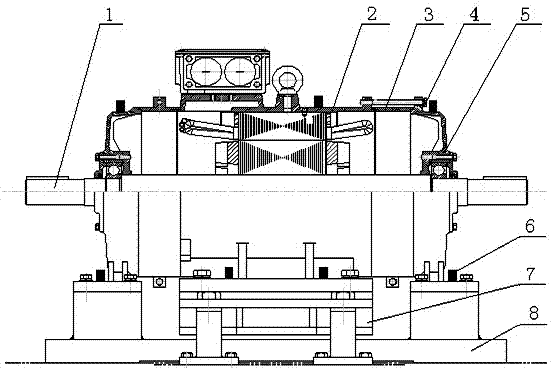

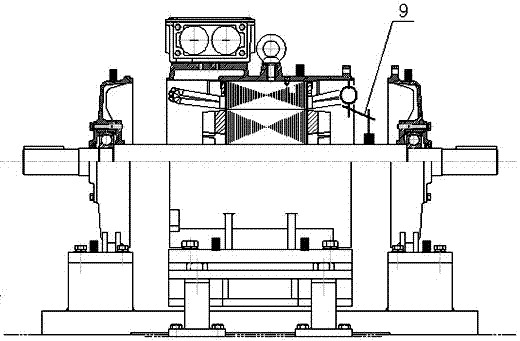

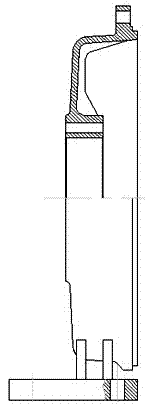

[0022] The present invention uses the test motor to complete the physical separation test of the vibration characteristics of the stator and the rotor, such as figure 1 The schematic diagram of the structure of the motor without the transition sleeve is shown, mainly including the rotor 1, the stator 2, the transition sleeve 3, the front and rear bearing end covers 5, the stator base 7 and the rotor base 8. Both the front and rear bearing covers 5 and the stator 2 have mounting feet, the front and rear bearing covers 5 and the rotor 1 are installed on the rotor base 8, the stator 2 is installed on the stator base 7, and the initial state is that the front and rear bearing covers 5 and The stator 2 is connected by the transition sleeve 3 and the bolt 4. When the transition sleeve 3 is removed, the rotor 1 and the stator 2 are respectively fixed on different bases, thereby realizing the physical separation of the vibration of the rotor 1 and the stator 2.

[0023] The specific i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com