Welding apparatus

A welding device and welding condition technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inconvenient management of multiple keys, complicated user interface, and high price of key switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

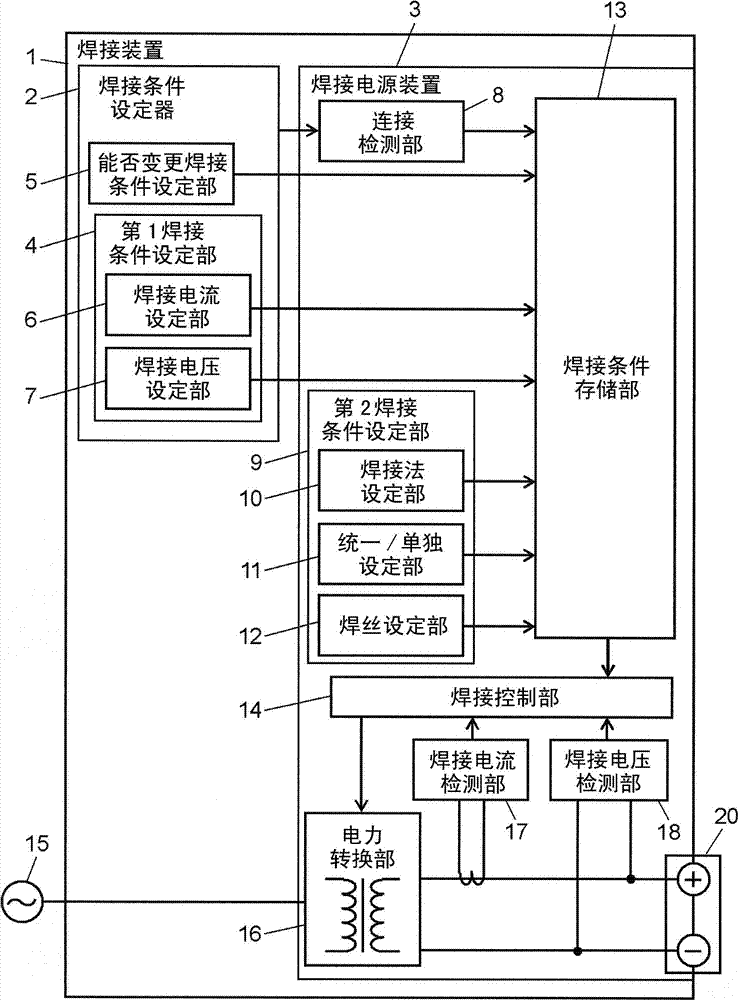

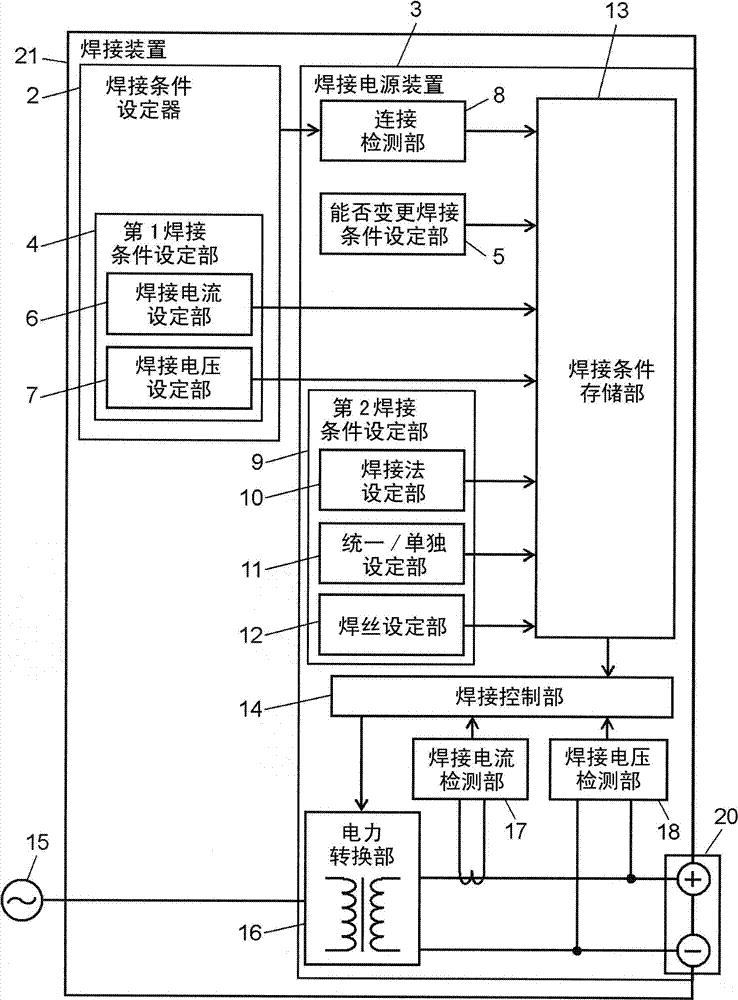

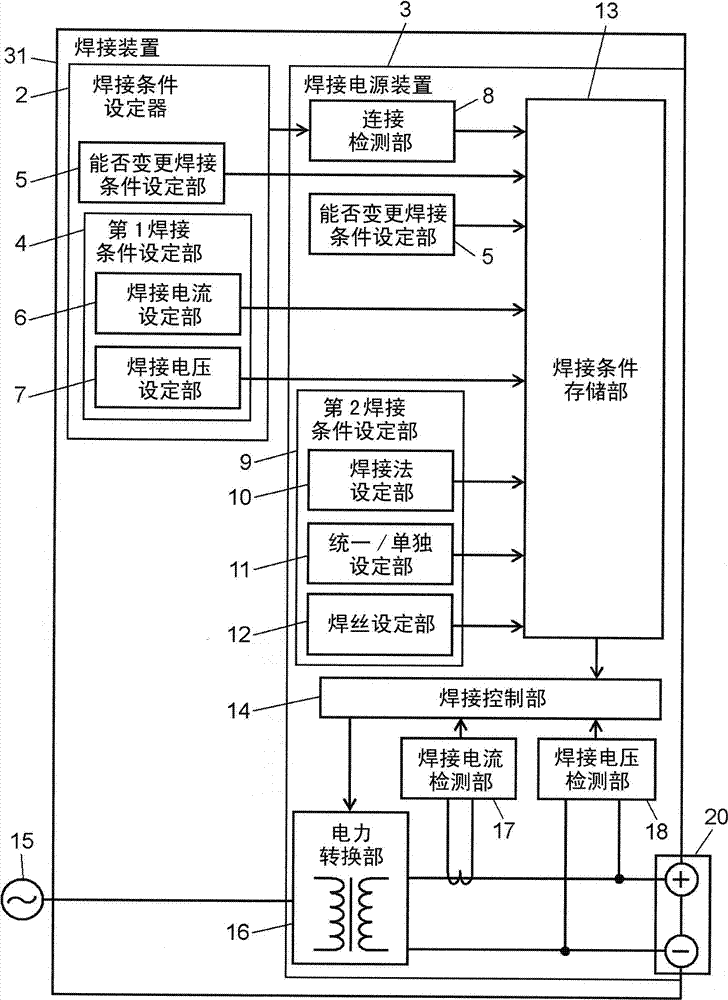

[0024] figure 1 It is a figure which shows the schematic structure of the welding apparatus 1 in Embodiment 1 of this invention. figure 2 It is a figure which shows the schematic structure of another welding apparatus 21 in Embodiment 1 of this invention. figure 2 The welding device 21 with figure 1 The welding device 1 differs in that, figure 2 The possibility of changing the welding condition setting part 5 is included in the welding power supply device 3, and figure 1 The changeable welding condition setting unit 5 is included in the welding condition setting unit 2 . image 3 It is a figure which shows the schematic structure of still another welding apparatus 31 in Embodiment 1 of this invention. image 3 The welding device 31 with figure 1 The welding device 1 and figure 2 The welding device 21 differs in that, image 3 The changeable welding condition setting unit 5 is included in the welding condition setter 2 and the welding power supply device 3 respec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap