Thermal expansion type ultrahigh-pressure energy conservation device

An energy conversion device and thermal expansion technology, applied in injection devices, liquid injection devices, etc., can solve problems such as high requirements for seals, affecting high-pressure injection, failing to meet sealing requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

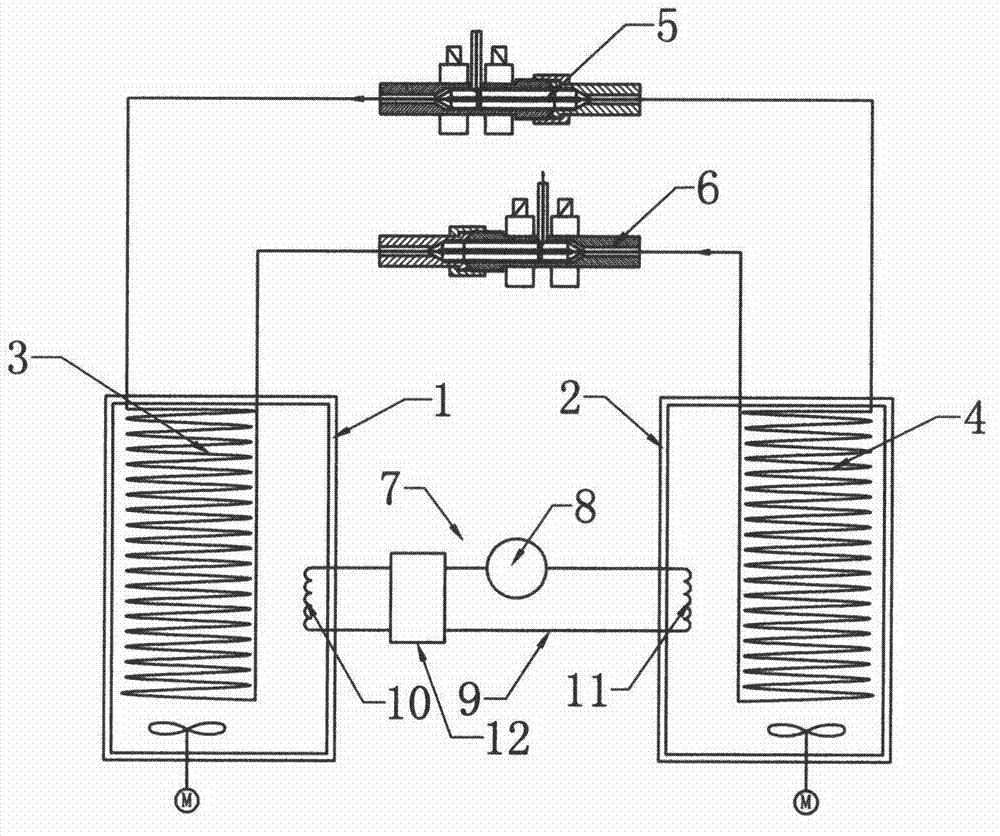

[0015] Such as figure 1 As shown, the thermal expansion type ultra-high pressure energy conversion device of the present invention includes No. 1 cold and heat exchange water tank 1 and No. 2 cold and heat exchange water tank 2, and No. 1 cold and heat exchange pipe 3 and No. Cooling and heat exchange pipe 4; No. 1 cold and heat exchanging pipe 3 and No. 2 cold and heat exchanging pipe 4 are provided with replenishing water switching valve 5 and spray water switching valve 6 respectively connecting the two cold and heat exchanging pipes end to end; water replenishing switching valve 5 and water spray switching valve 6 are set in the opposite direction, so that alternate water spray and alternate water intake can be realized and the liquid medium in the two cold and heat exchange pipes can be alternately switched between cold and heat; A cooling and heating switching device 7 that can switch the liquid medium in the two cold and heat exchanging water tanks between cold and hot,...

Embodiment 2

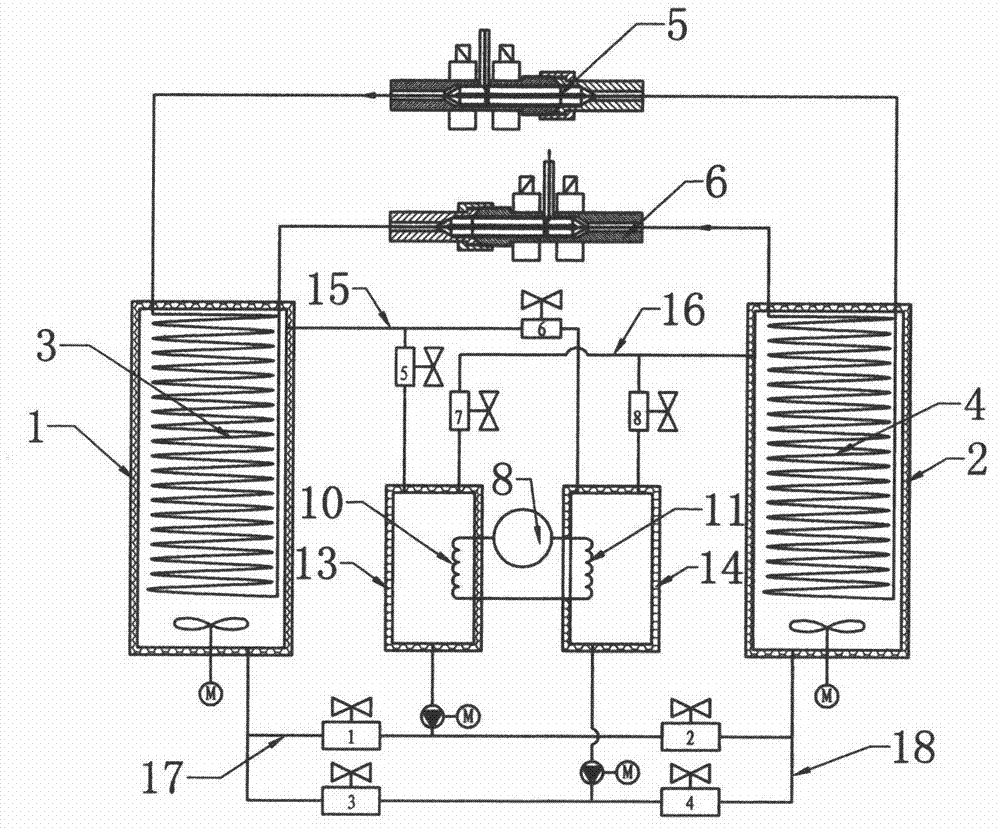

[0018] In this embodiment, the cooling and heating switching device 7 includes a heat pump 8 and a cold and hot medium circulation pipeline 9 connected to the heat pump 8; 11. The evaporator 10 and the condenser 11 are respectively arranged in the hot water tank 13 and the cold water tank 14, and the hot water tank 13 and the cold water tank 14 are respectively connected with the No. 1 cold and heat exchange water tank 1 and the No. 2 cold and heat exchange water tank 2 There are interconnected branches, and a reversing device that can change the flow direction of the medium in the heat pump is arranged on the branch, and the cold and hot media at the cold and heat exchange end can be switched alternately through the reversing device; among them, there are four branches, and they are respectively It is to connect No. 1 water tank 13 and No. 2 water tank 14 in parallel to No. 1 branch 15 on No. 1 cold and heat exchange water tank 1; connect No. 1 water tank 13 and No. 2 water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com