Flaring mechanism for pipe expander

A tube expander and flaring tube technology, applied in the field of flaring mechanism, can solve the problems of increasing operation difficulty and operation time, high assembly process installation, easy to produce defective products, etc., so as to reduce operation time and operation difficulty and save space , The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in detail:

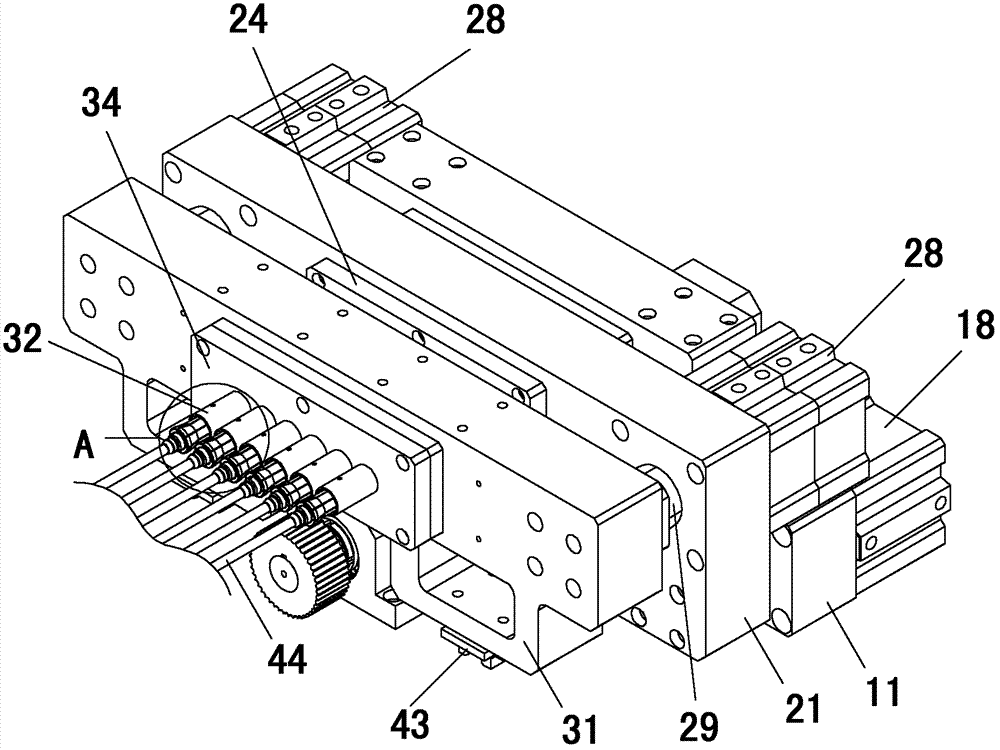

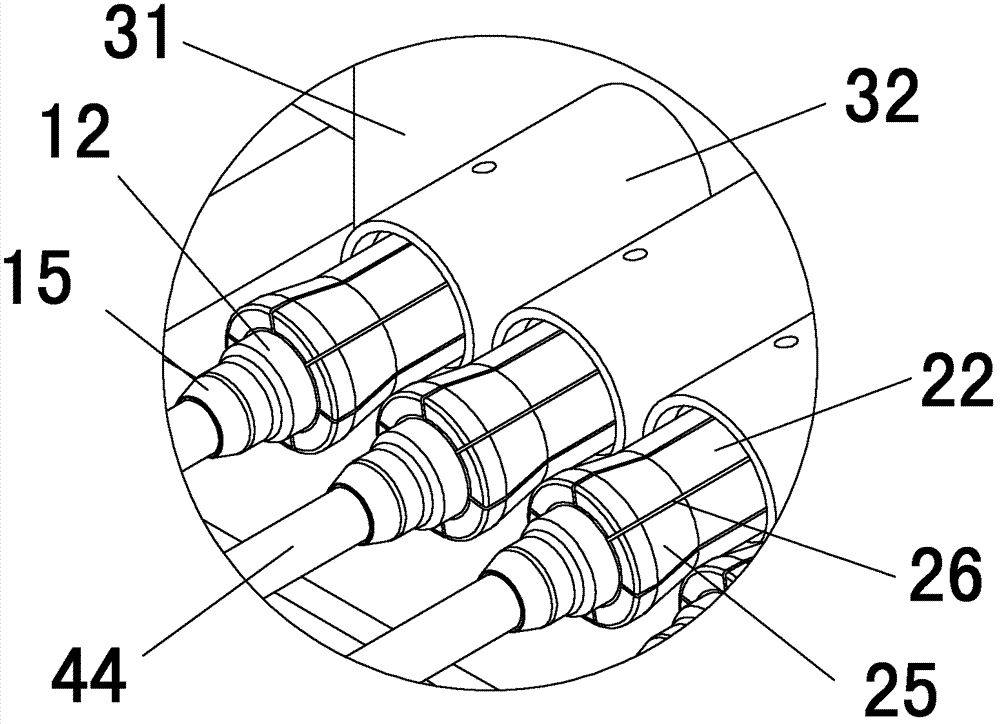

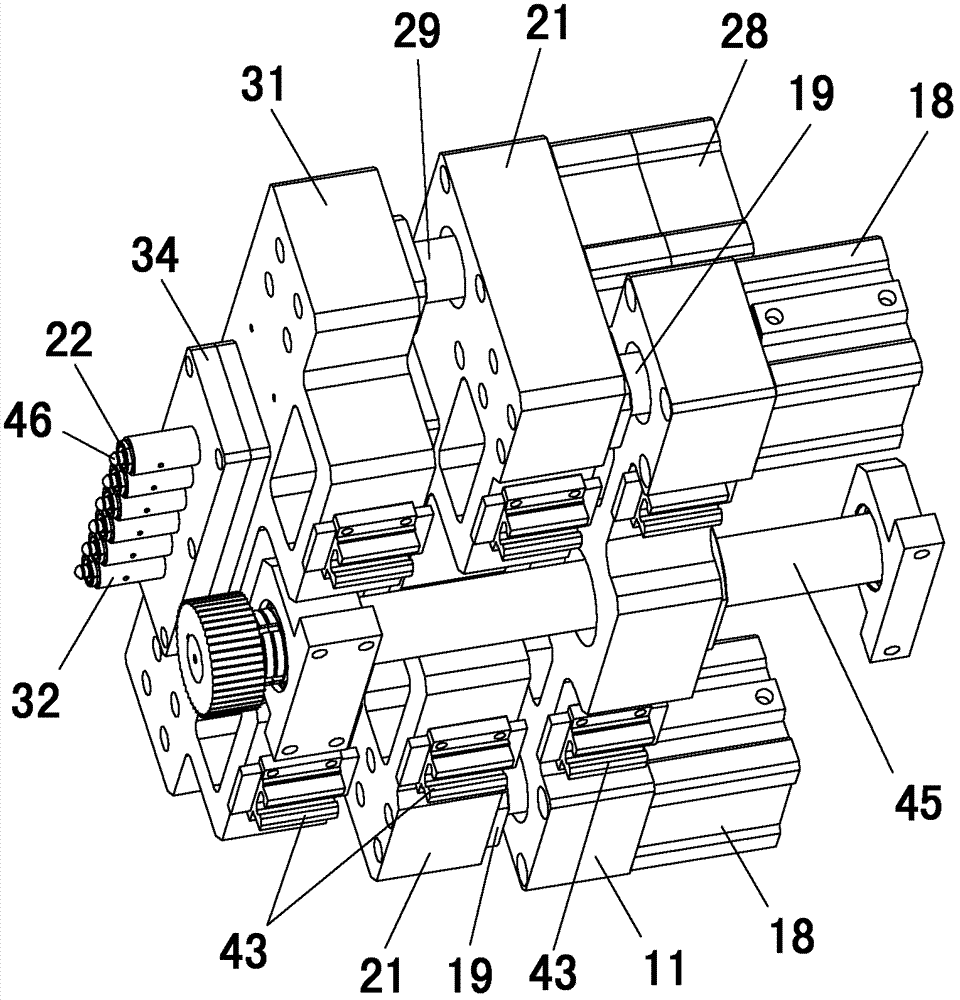

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 as shown,

[0024] The invention is applied in a tube expander and is located on a guide rail close to one end of a U-shaped tube fixing bracket.

[0025] The present invention includes a flared mounting plate 11 connected to the guide rail and a flared pipe 12 installed on the flared mounting plate 11, the flared mounting plate 11 has a first through hole 13, and the flared mounting plate 11 is installed on the front side The first fixed plate 14 is arranged to block the first through hole 13, and several flared tube mounting holes are provided on the first fixed plate 14, and the flared tube 12 is installed in the flared tube mounting hole, and the flared tube 12 front end Flaring head 15 is provided on the outside. The expansion rod 44 of the tube expander passes through the first through hole 13 from the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap