System and method for realizing real-time tracking of casting blank

A real-time tracking and billet technology, applied in the field of metallurgical continuous casting, can solve the problem that abnormal events cannot accurately match the billet, and achieve the effects of timeliness and effectiveness, improved accuracy, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

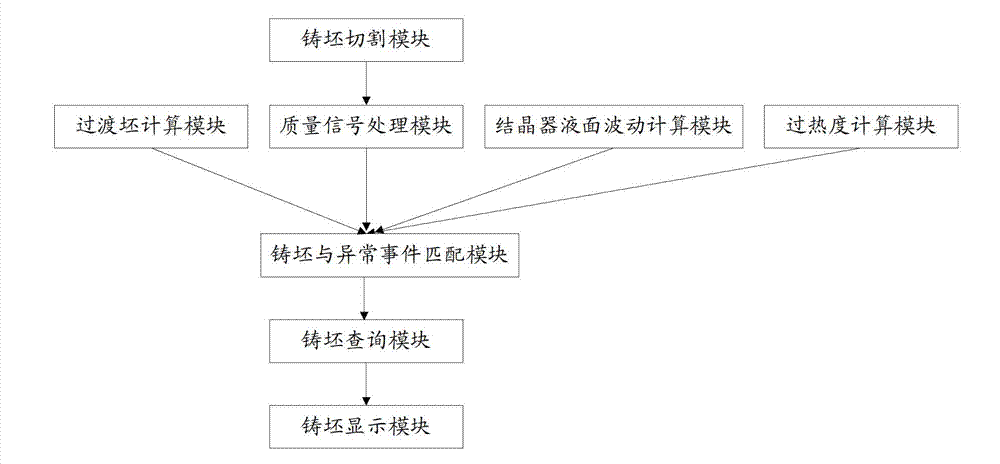

[0050] see figure 1 , a system for real-time tracking of slab provided by an embodiment of the present invention, including a slab cutting module, a quality signal processing module, a crystallizer liquid level fluctuation calculation module, a transition slab calculation module, a superheat calculation module, and a slab and abnormal event matching module;

[0051]The slab cutting module is used to calculate the casting length corresponding to the slab; the quality signal processing module is used to convert different events affecting the quality of the slab during the casting process into different signals, and simultaneously calculate the casting length corresponding to the signal; The crystallizer liquid level fluctuation calculation module is used to calculate the casting length corresponding to the mold liquid level fluctuation data of the slab; the transition slab calculation module is used to calculate the casting length corresponding to the transition slab of the slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com