Damping boring tool

A boring tool and boring bar technology, which is applied in the accessories of tool holders, tools for lathes, turning equipment, etc., can solve the problems of boring bar vibration, reduce production efficiency, waste tool materials, etc., and reduce fluctuation and eccentricity Cutting force, improvement of processing quality, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

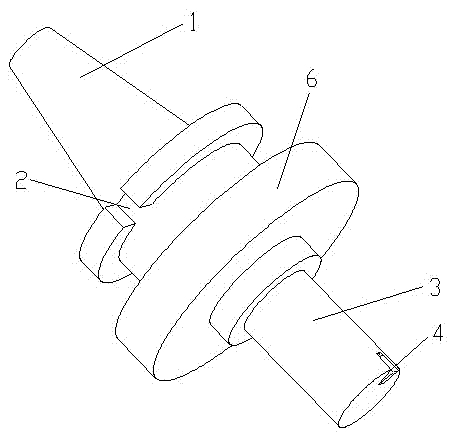

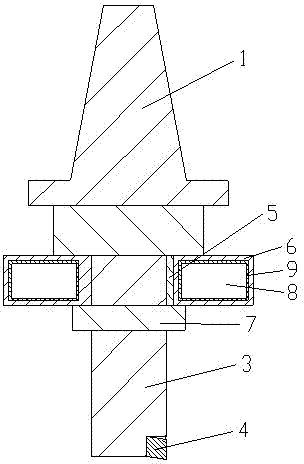

[0012] as attached figure 1 , 2 The shown vibration-damping boring tool of the present invention includes a taper shank 1 inserted into a machine tool, a positioning slot 2, a boring bar 3 and a blade 4; the boring bar 3 is arranged at the lower part of the taper shank 1; the The bottom of the boring bar 3 is equipped with a blade 4; the boring bar 3 is connected to a damping disc 6 through a key 5; a limit block 7 is provided under the damping disc 6; an annular groove is opened in the damping disc 6 8; An elastic vibration-absorbing layer 9 is provided on the inner wall of the vibration-damping disc 6 close to the annular groove 8 .

[0013] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0014] The vibration-damping boring tool of the present invention reduces the fluctuation and ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com