Overload protection device used for sheet-fed automatic die cutting machine

An overload protection, die-cutting machine technology, applied in metal processing, etc., can solve the problems of large load, immediate stop operation of gripper row 6', and unreliable safety protection of large automatic die-cutting machines, etc., to improve the safety level , Improve the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

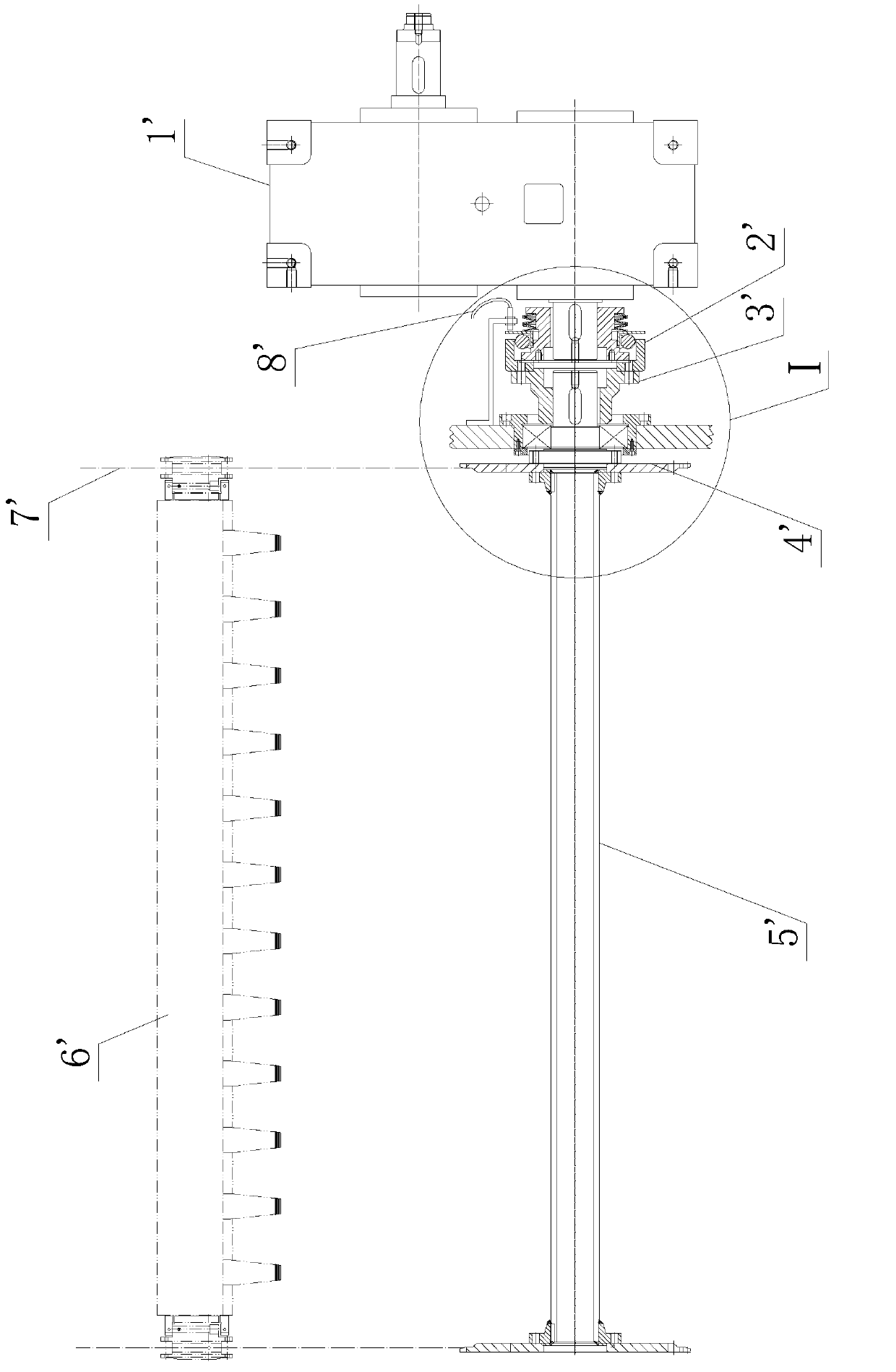

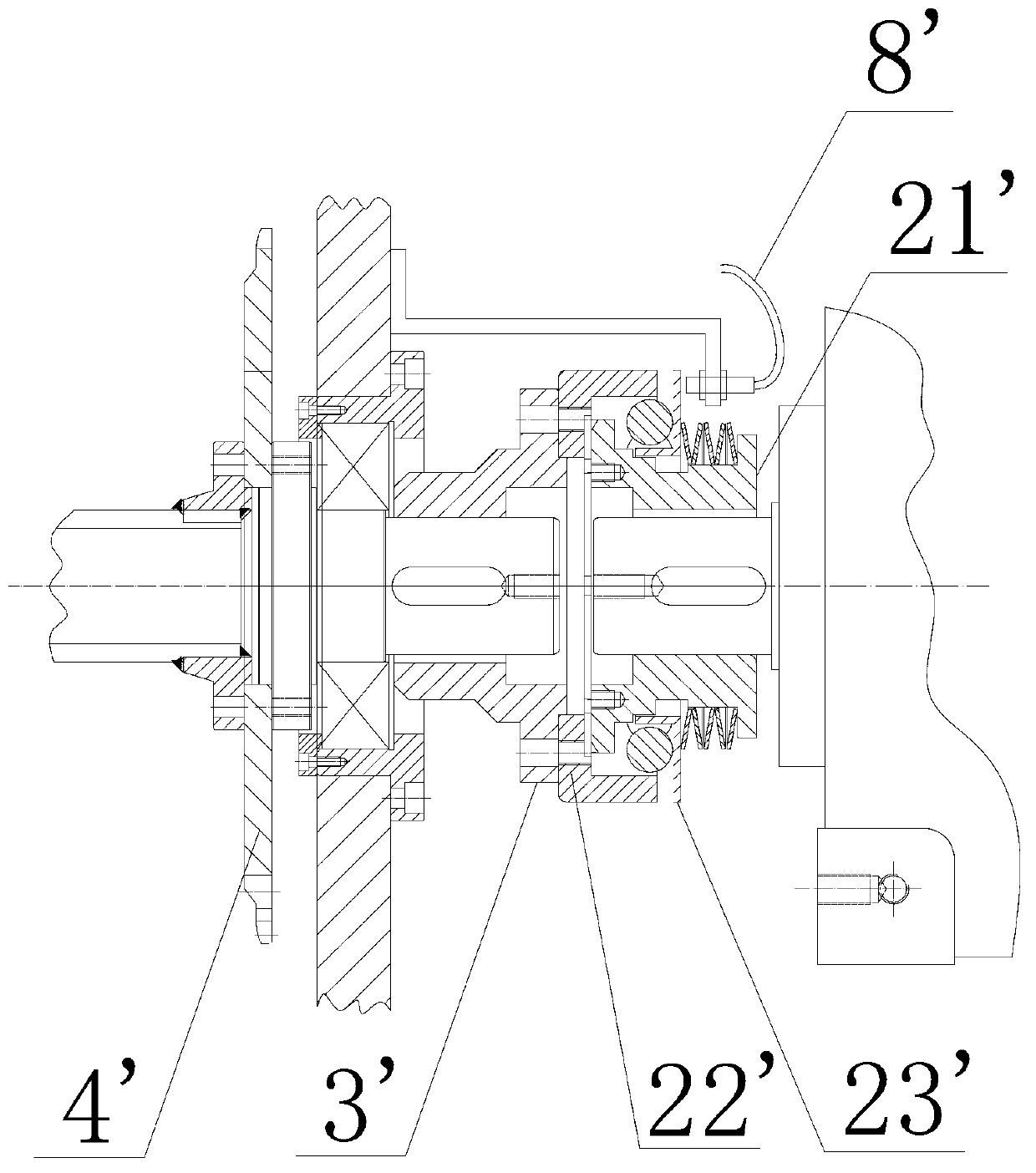

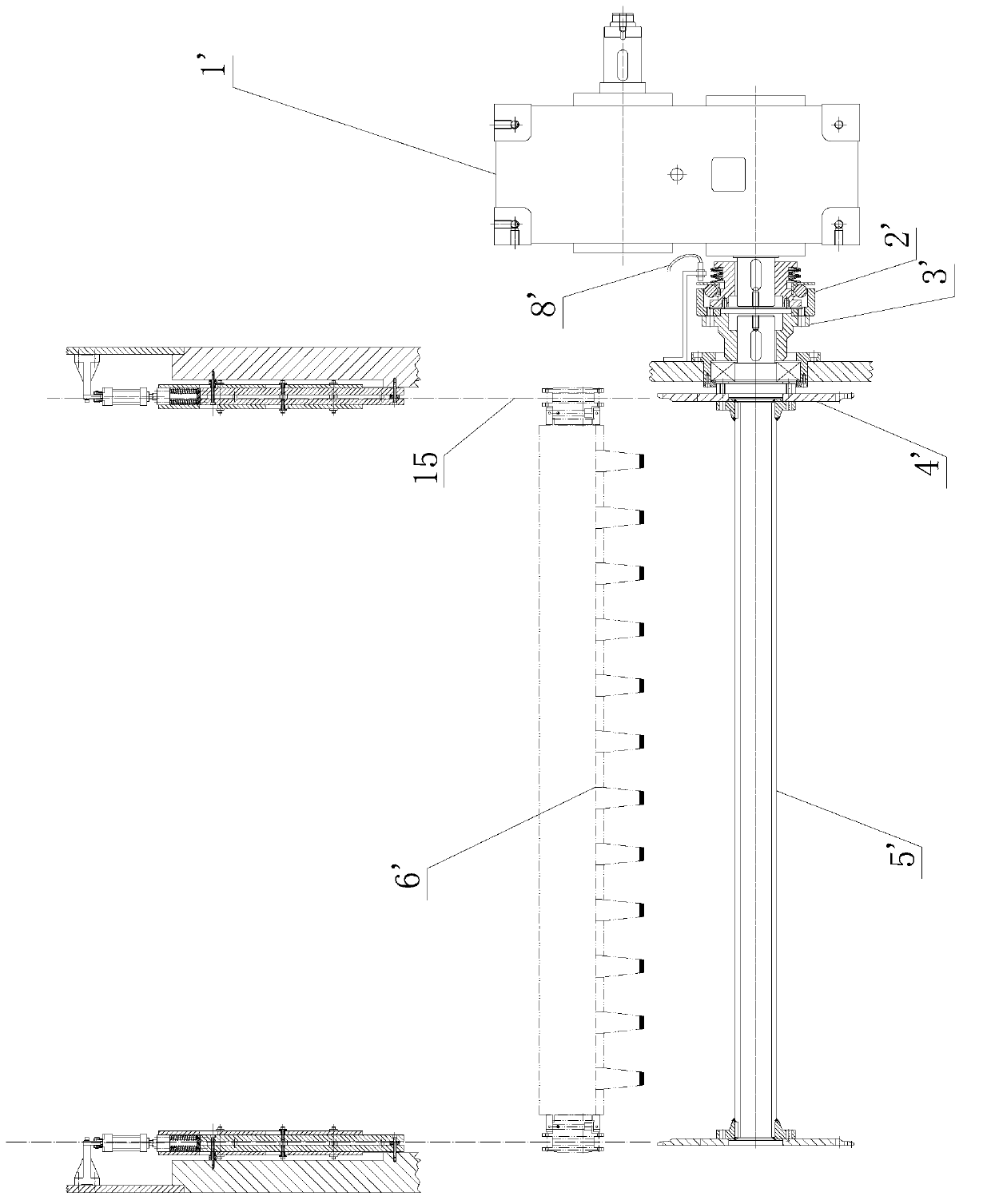

[0043] The overload protection device for sheet-fed automatic die-cutting machine provided by the present invention, such as image 3As shown, it includes a torque limiter 2', which is installed between an intermittent power output device (such as an intermittent mechanism such as an intermittent box 1') and a flange 3', which can trigger an induction switch 8 ', the structure of the torque limiter 2' and the form of the trigger sensor switch 8' are public technologies, so they will not be repeated here. The flange 3' is installed on a main sprocket shaft 5', on which the main sprocket 4' is installed, and the main chain 15 driven by the main sprocket 4' is fixedly connected with the gripper row 6' .

[0044] The overload protection device of the present invention also includes two safety hook mechanisms, such as Figure 5 , Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com