Automobile roof rack

A technology for luggage racks and automobiles, which is applied to vehicle parts, additional accessories, transportation and packaging, etc., can solve the problems of reduced leg strength, over-prioritized functions, and reduced strength, and achieves the effect of improving appearance, strengthening strength, and improving appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

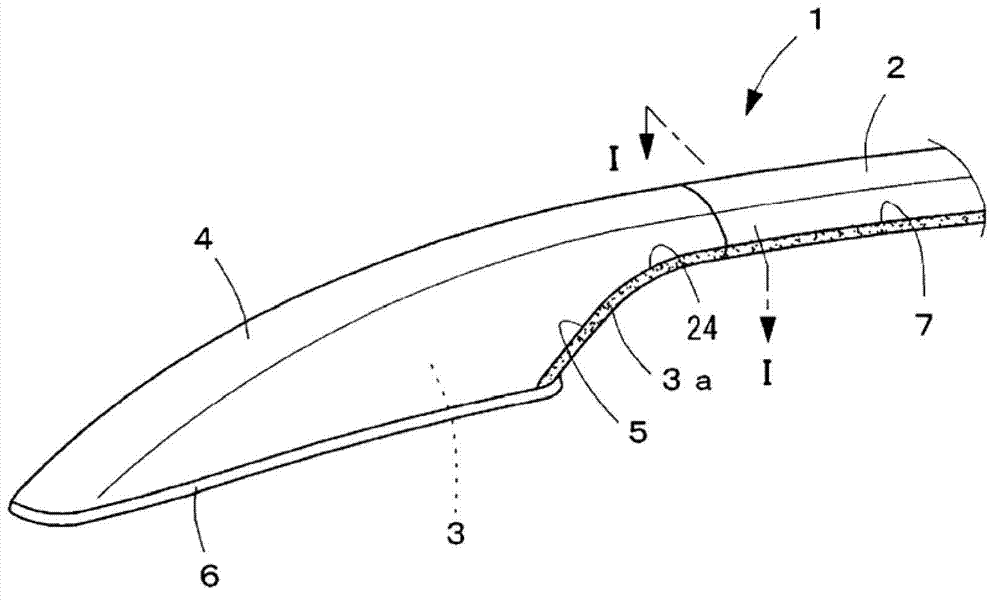

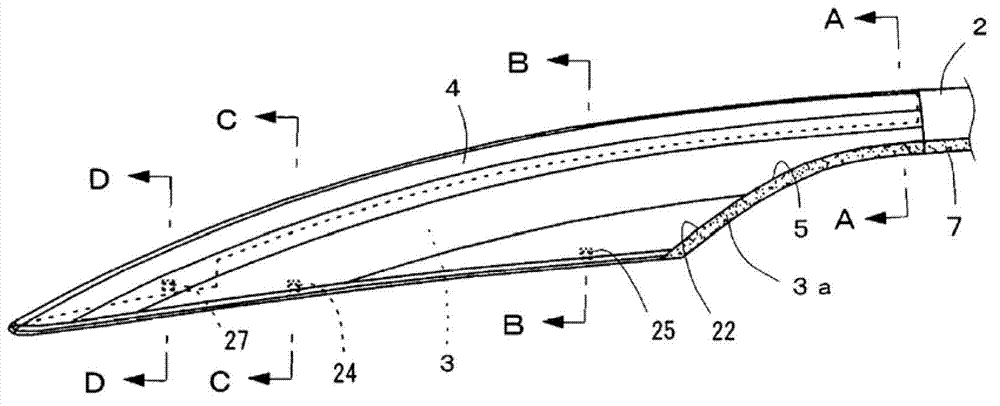

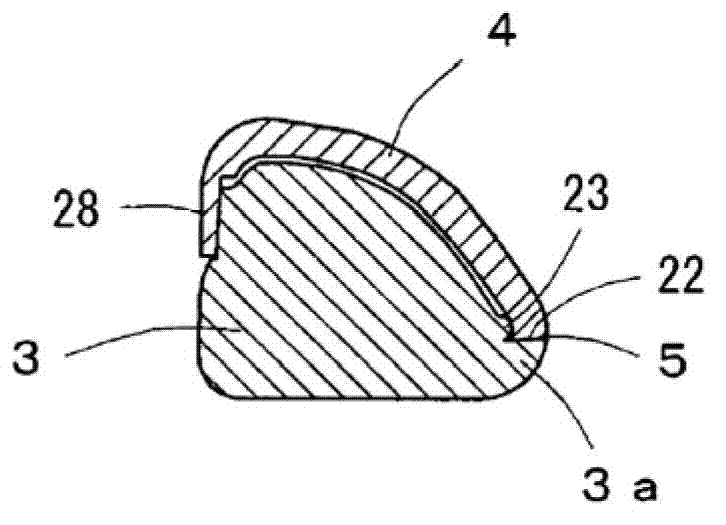

[0072] Hereinafter, the present invention will be described with reference to the illustrated embodiments. Figure 1 to Figure 1 In 7, 1 is a roof rack for automobiles, which is covered by a pair of left and right roof racks 2 made of metal pipes, and synthetic resin legs 3 installed at the front and rear ends of the roof rack 2. The leg part 3 rear part except the synthetic resin leg cover 4 of the upper side peripheral surface of the decorative part mentioned later is constituted, and the boundary part between the lower edge part of the outside rear of the leg part cover 4 and the above-mentioned decorative part is formed to cover it. Divide the curved line-like dividing line (see 切り)5. In the figure, 6 is a sealing gasket assembled under the leg 3 .

[0073] The above-mentioned roof rack 2 is formed by extruding or pulling out aluminum, bending it in a three-dimensional direction, forming its cross-sectional shape into a trapezoidal or triangular shape as shown in FIG. 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com