Cloth rolling method for cloth rolling machine

A cloth winding machine and cloth rolling roller technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of large power resource loss, looseness, damage, etc., and achieves convenient operation, simple structure, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

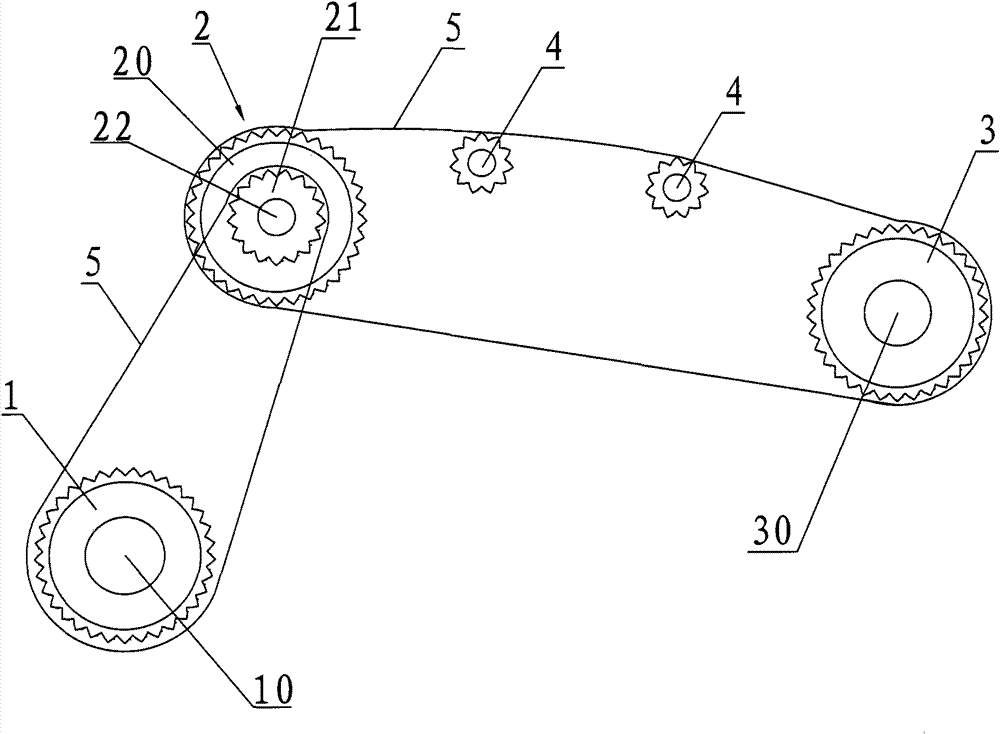

[0010] Such as figure 1 As shown, the cloth rolling method of a cloth rolling machine in this embodiment is that the cloth is rolled up and formed by the conveying roller and the cloth rolling roller under the action of the transmission device, wherein the transmission device includes a transmission device arranged on the frame Motor, the first gear 1 matched with the main shaft 10 of the transmission motor, the second gear 2 arranged at the two ends of the cloth feeding roller shaft 22, the third gear 3 arranged at the two ends of the cloth winding roller shaft 30, the transmission chain 4 and the fixed A tensioning gear 5 arranged on the frame between the second gear 2 and the third gear 3, wherein the second gear 2 includes two coaxial large gears 20 and pinion 21 with a gear outer diameter of 2:1 , the method is as follows: (a), the pinion 21 of the first gear 1 and the second gear 2 is connected through the chain 4, and the pinion 21 is matched with the roller shaft 22 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com