Weaving method and weaving device in a loom

A loom and fabric weaving technology, applied in the field of loom weaving and weaving devices, can solve problems such as the reduction of weaving efficiency, achieve the effects of shortening the deceleration period, avoiding electrical faults, and simplifying the amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

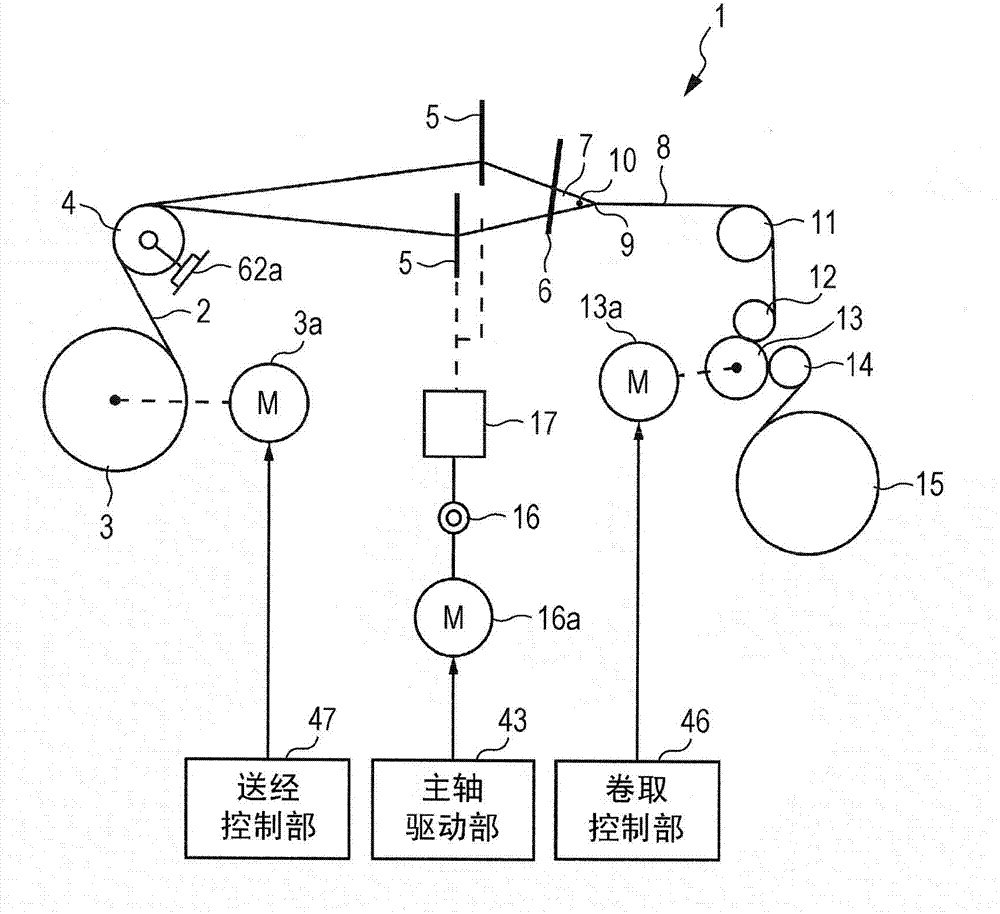

[0052] figure 1 Shown is the overall configuration of the loom 1 to which the present invention is applied, particularly the parts related to the let-off operation of the warp yarn 2 and the take-up operation of the fabric 8 . figure 1 Among them, many warp yarns 2 are sent out in sheets from the warp beam 3, pass through a plurality of heddles 5, 5, ... and reed 6 through the reverse roller 4, and move through the opening of the heddle 5 to warp up and down. 2, 2 forms the opening 7 and reaches the weaving front 9 of the fabric 8. In addition, a tension sensor 62a is installed at the supporting position of the reversing roller 4, and detects the tension value of the warp yarn 2 according to the resultant force of all the warp yarns 2 acting there.

[0053] On the other hand, after the weft yarn 10 is inserted in the opening 7 of the upper and lower warp yarns 2 and 2, it is beaten up before weaving 9 by the beating motion of the reed 6, and becomes the structure of the fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com