Transmission tower plate-type three-rope foundation structure

A transmission pole tower plate type and infrastructure technology, which is applied in infrastructure engineering, construction, etc., can solve problems such as difficulty in process and size inspection and construction difficulty, achieve high safety and reliability, reduce excavation depth, and improve safety and reliability. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

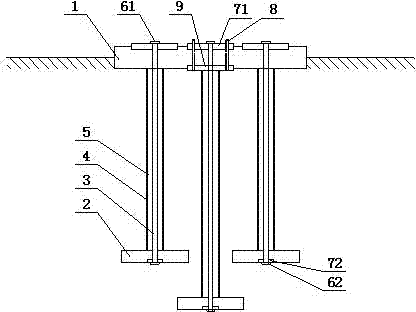

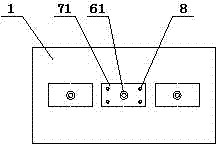

[0013] Such as Figure 1-2 As shown, the transmission pole tower-type three-cable foundation structure described in the embodiment of the present invention includes an upper slab 1 laid on the ground surface and three lower slabs 2 buried in the ground, between the upper slab 1 and each lower slab 2 Respectively connected by a steel strand rope 3, the three lower plates 2 are set in a straight line, the length of the steel strand rope 3 in the middle is greater than the length of the steel strand rope 3 on both sides, and the steel strand ropes on both sides 3 are equal in length, and each steel strand 3 between the upper plate 1 and the lower plate 2 is provided with a rubber sleeve 4, and each of the two ends of the rubber sleeve 4 is connected with the upper plate 1 and the lower plate 2 respectively. A lower plate 2 is in contact, and the inside of the rubber sleeve 4 is filled with anti-corrosion filler 5; the two ends of the steel strand 3 are respectively provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com