Coal plough

A technology of coal plow and plow head, which is applied in the directions of slitting machinery, driving device, earthwork drilling, etc., can solve the problems of increasing the driving power of a single machine, increasing the coal plow, etc., and achieve the effect of solving the increase of the power of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The technical solution of the present invention will be described below with reference to the accompanying drawings and in combination with embodiments.

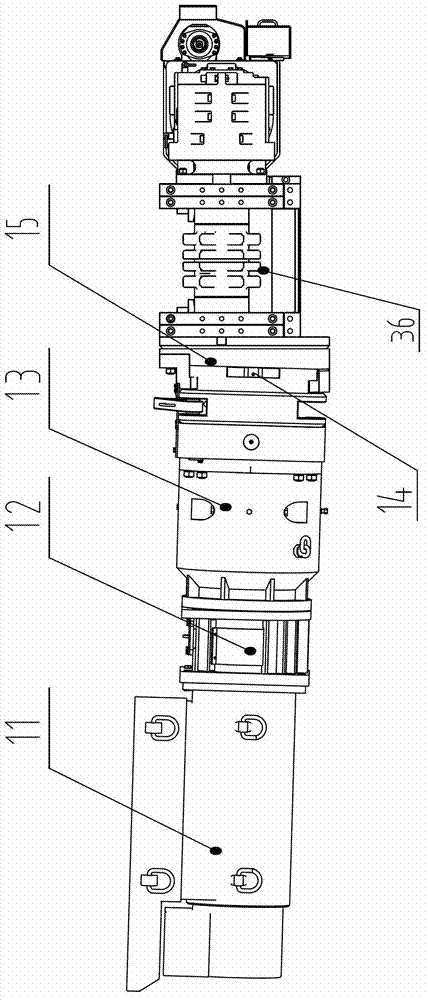

[0040] The basic idea of the present invention is to design a coal plow, which adopts double-chain traction, and the two ends of the machine head and machine tail are driven

[0041] Below in conjunction with accompanying drawing, each preferred embodiment of the present invention is described further:

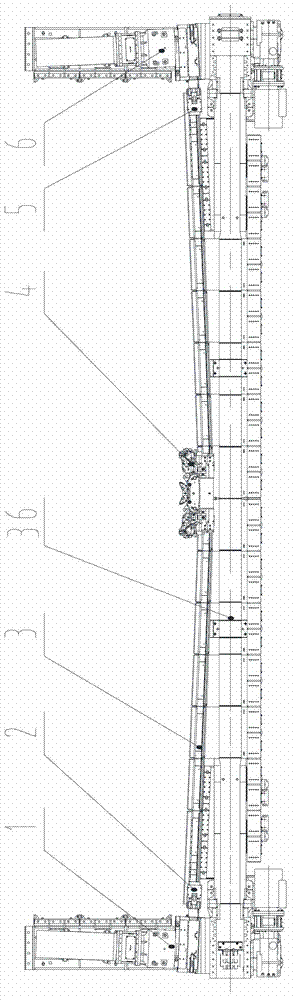

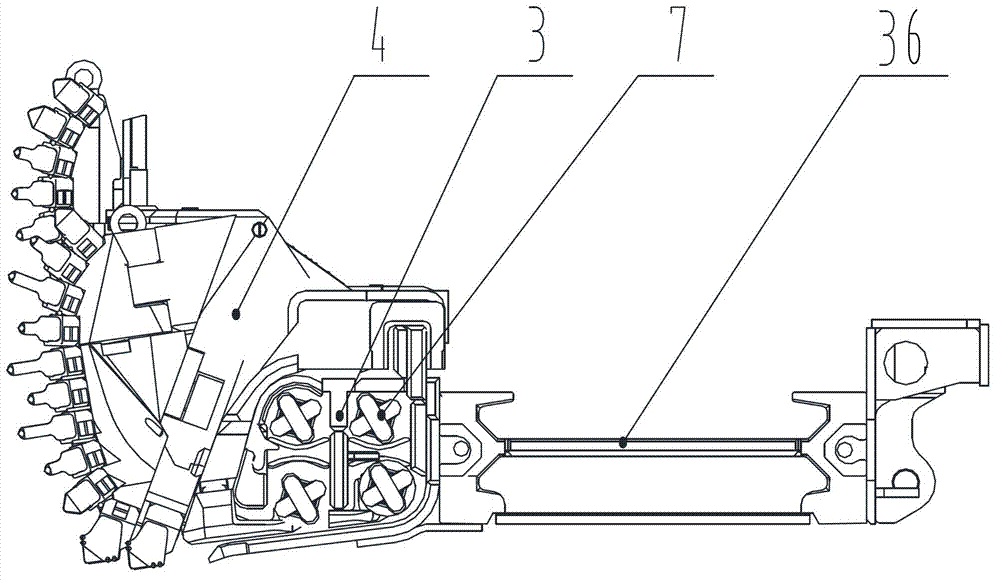

[0042] refer to figure 1 with figure 2 , shows the structure of the coal plow proposed in this embodiment, and the coal plow includes: a coal plow conveying part 36, a plow head 4, a sliding frame 3 matched therewith, and a double infinite chain 7.

[0043] In this embodiment, one end of the plow conveying part 36 is provided with a head drive device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com