Differential pressure feedback type flow divider valve

A feedback type, diverter valve technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem that diverter valves cannot realize the lifting movement of equal-thrust single-acting hydraulic cylinders, and are not suitable for walking agricultural machines, Problems such as the bulky size of the diverter valve, to achieve the effect of flexible and convenient configuration, less difficulty in processing, and changing complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

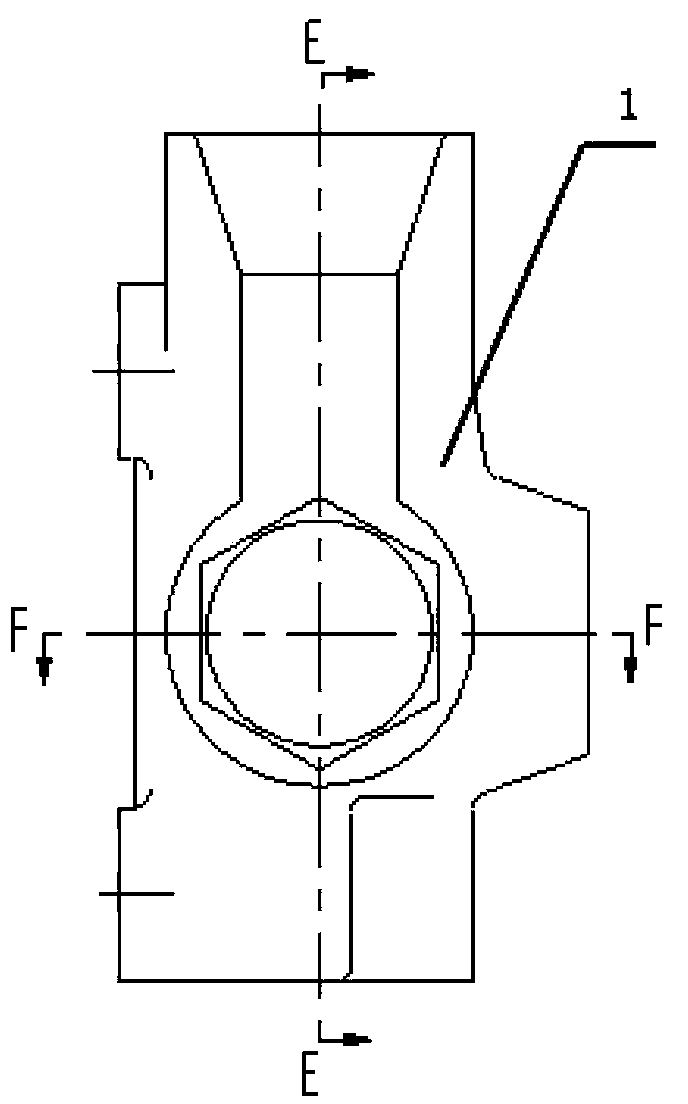

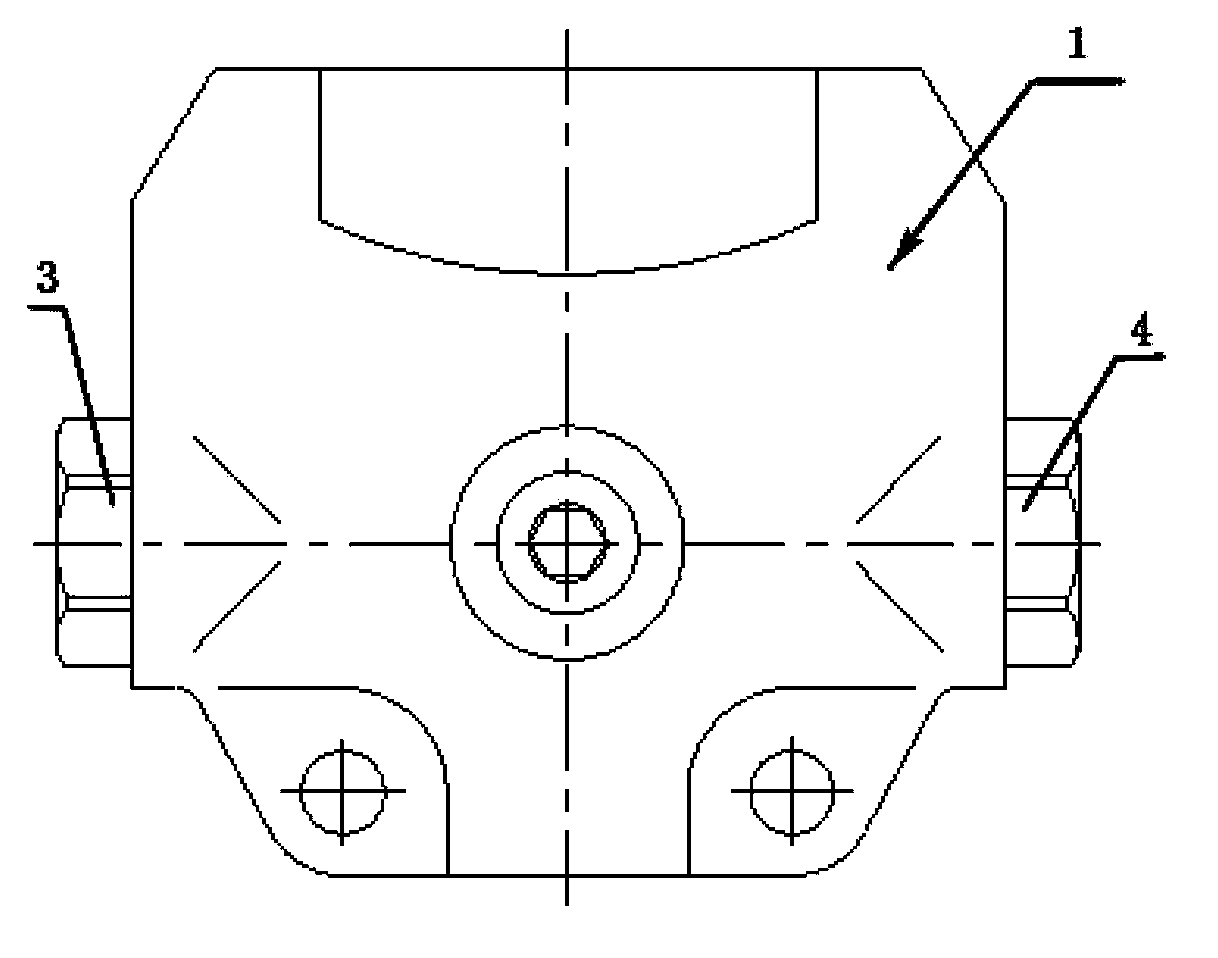

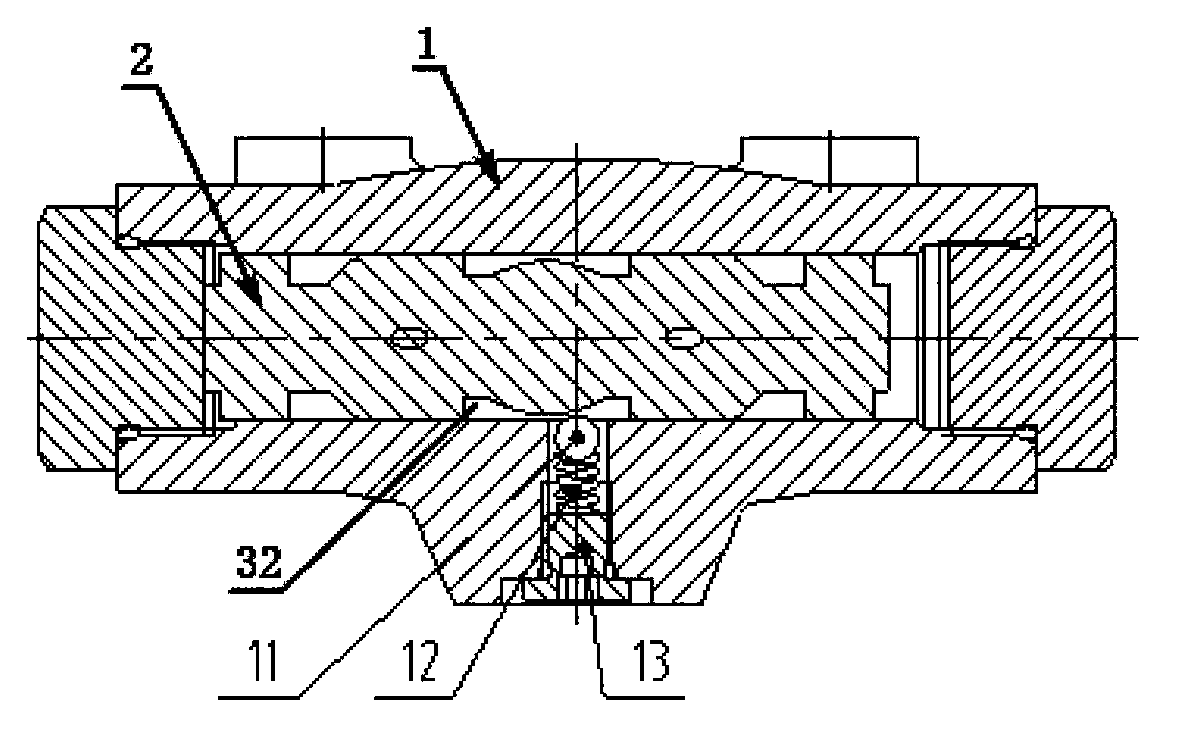

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

[0026] see Figure 1 to Figure 4 The differential pressure feedback diverter valve shown includes a valve body 1, a reversing valve core 2 matching with the valve body hole in the middle of the valve body 1, a first screw plug 3 matching with the left end of the valve body hole and The second screw plug 4 matched with the right end of the valve body hole, the right end of the first screw plug 3, the left end of the reversing valve core 2 and the inner wall of the left end of the valve body hole form the A cavity flow channel 29, and the second screw plug The left end of 4, the right end of the reversing valve core 2 and the inner wall of the right end of the valve body hole form a B chamber flow channel 30, and ring grooves are respectively arranged on the left and right parts of the reversing valve core 2, and the reversing valve core The middle part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com