Ship-borne attitude and angle sensor detection method

An angle sensor and detection method technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of non-uniform specifications, hidden dangers of data information quality, reliability, accuracy and credibility of observation data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0059] Examples and discussions:

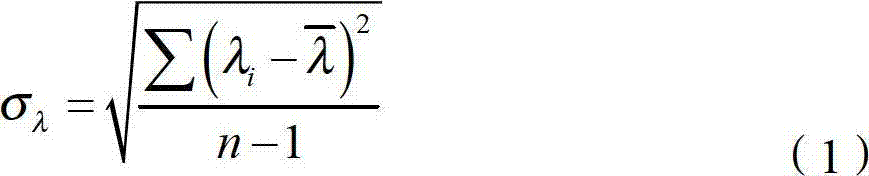

[0060] The detection accuracy of the roll and pitch of the attitude sensor detection device is 0.001 degree, and the detection error after compensation is 0.005 degree.

[0061] The static accuracy of the roll and pitch of the S-108 model attitude sensor is 0.02° (RMS), and the accuracy of the up and down heave within ±10m is 5cm or 5%. The static internal accuracy of the instrument obtained through the above detection process Both the test standard deviation and the external coincidence precision test standard deviation are smaller than the corresponding precision values, meeting the precision requirements.

[0062] The dynamic accuracy of the roll and pitch of the S-108 model attitude sensor is 0.03° (RMS), and the up and down heave accuracy is 5cm or 5%. The standard deviation of the accuracy test is less than the corresponding accuracy value, which meets the accuracy requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com