Heavy water reactor spent fuel dry storage shielded transport container

A technology for transporting containers and spent fuel, applied in the field of dry storage of spent fuel of heavy water reactors, can solve the problems of poor stability of a translation door drive mechanism, poor neutrality of gripper heads, poor equipment safety, etc., so as to improve safety and reliability. , The effect of improving alignment accuracy, reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

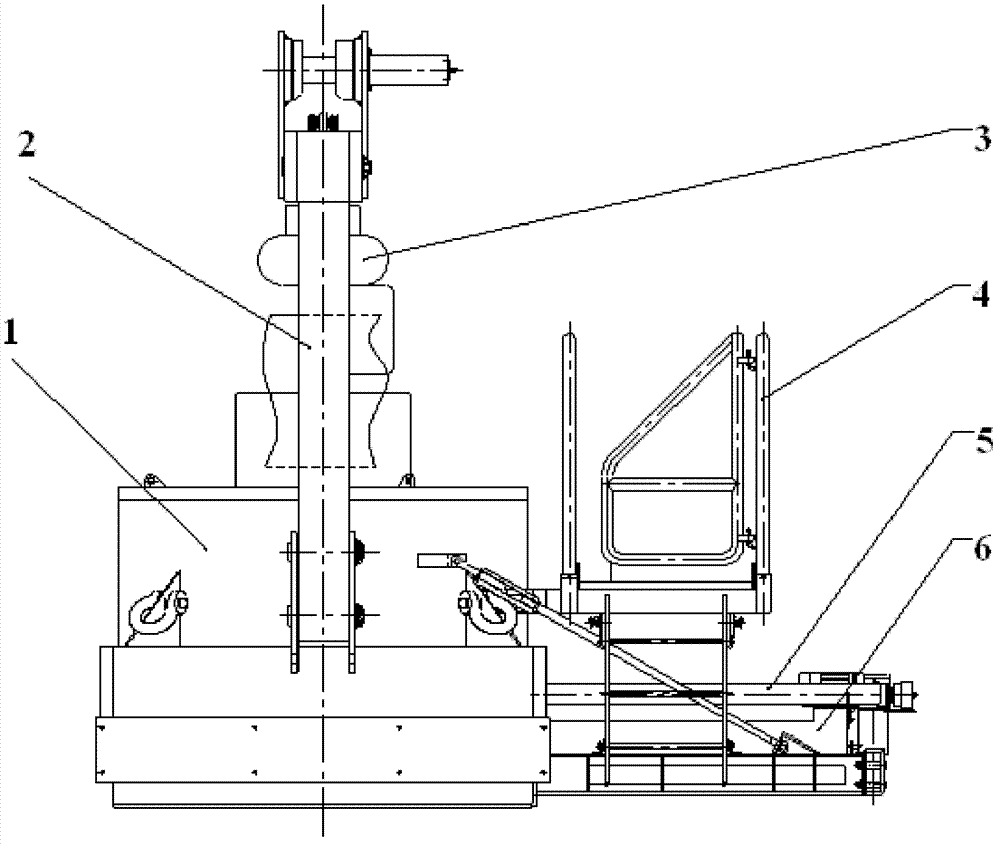

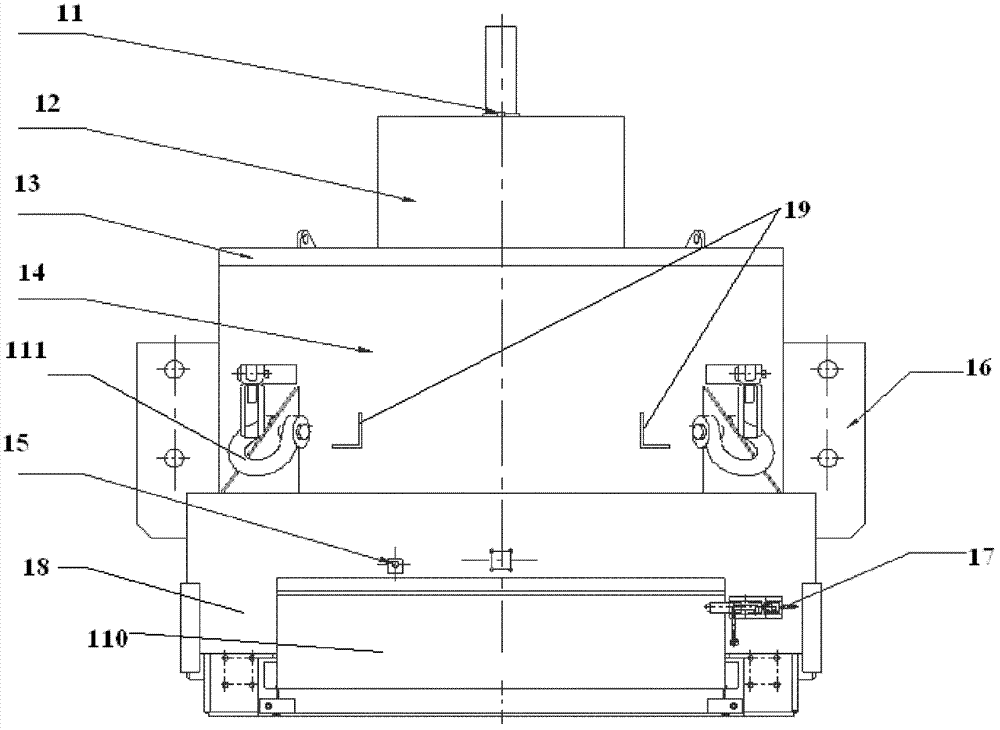

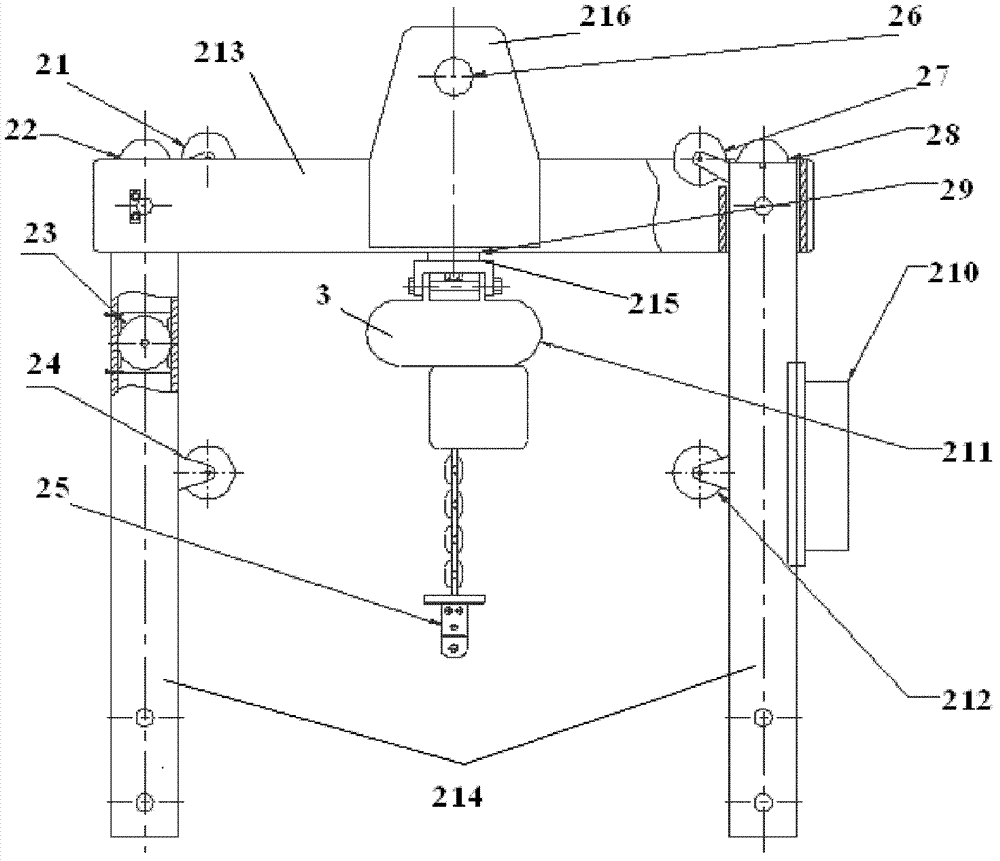

[0036] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the heavy water reactor spent fuel dry storage shielded transport container of the present invention includes a shielded cylinder 1, a suspension yoke assembly 2, an electric chain hoist 3, a bridge frame 4, a translation door drive mechanism 5 and a translation door 6; The yoke assembly 2 is composed of a horizontal beam 213 connected to the upper ends of two vertical connecting columns 214 located at both ends of the beam through pin shafts, and the lower ends of the two connecting columns 214 are respectively connected to the opposite sides of the shielding cylinder 1; The electric hoist 3 is installed at the lower end of the middle part of the beam 213 of the yoke assembly 2; a rectangular translation door slot 110 is opened on one side of the lower part of the shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com