Rapier and gripper weaving machine

A shuttle loom, rapier technology, applied in the field of gripper looms, can solve the problem that the wear-resistant element and the rapier cannot be guaranteed to be aligned and firm, the wear-resistant element, the gripper belt warp yarn and/or the guide hook are damaged, defective Fast and simple assembly, preventing unintentional relative movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

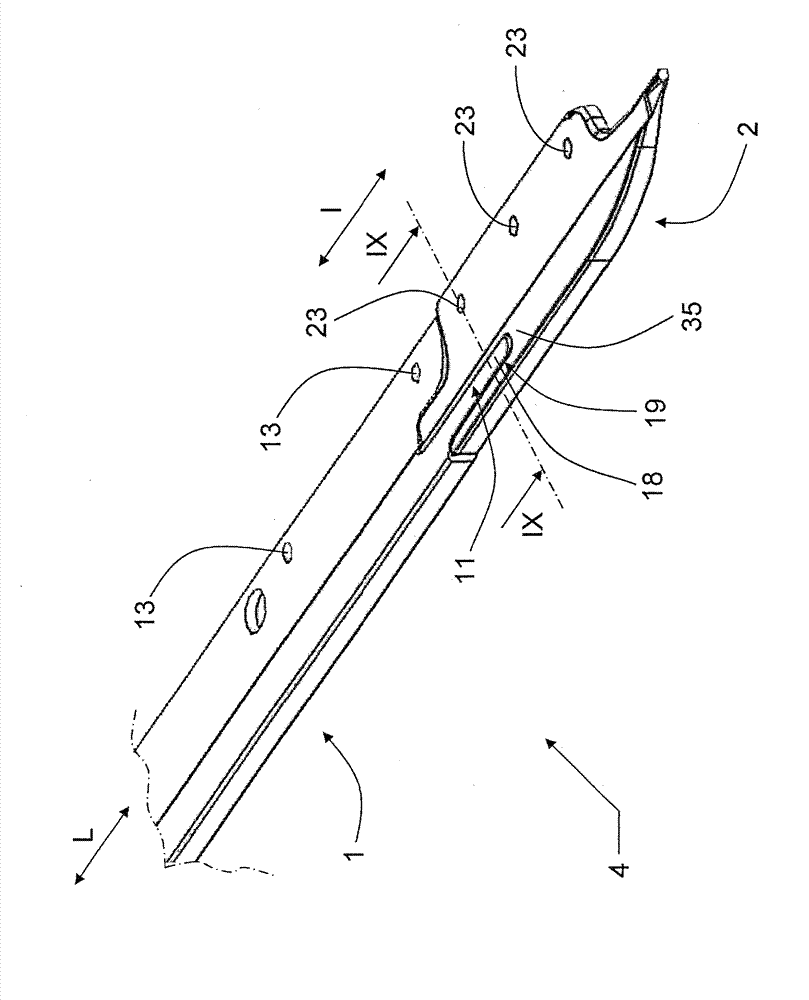

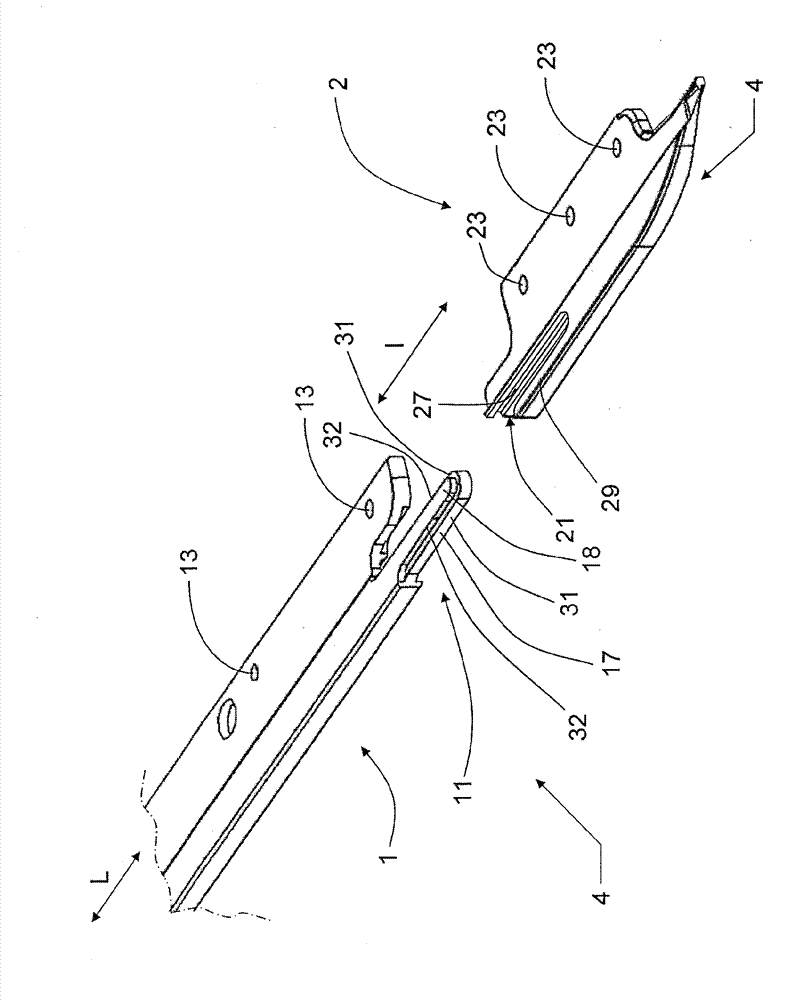

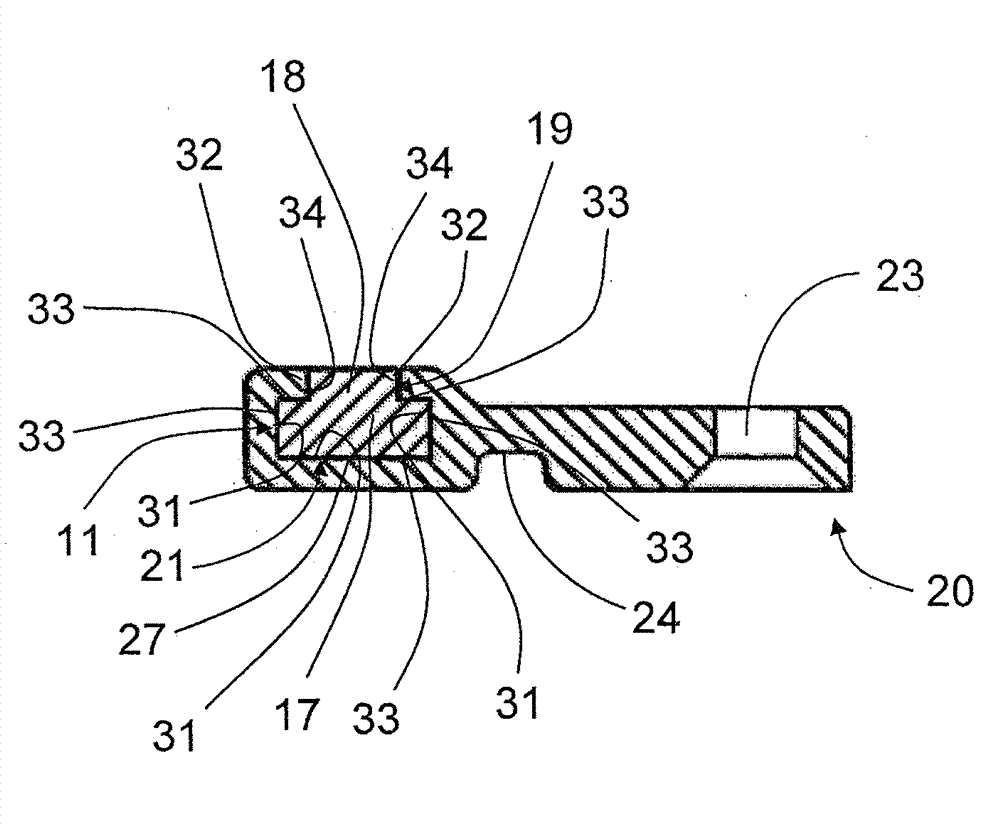

[0043] 1 to 5 show a first embodiment of a rapier 1 comprising a gripper belt 2 provided with a stiff top 10 and a wear element 20 possibly removably connected to the stiff top 10 . Figure 1 shows a view of the rigid top 10 and wear element 20 before they are connected. The rigid top 10 includes an elongated tongue 11 extending beyond the rigid top 10 and the wear element 20 includes a recess 21 with which the tongue 11 can cooperate. FIG. 2 shows a view of the connection of the rigid top 10 and the wear element 20 . FIG. 3 shows a view of the rapier 1 , wherein on the rigid top 10 and the wear element 20 the gripper 3 is connected to the rapier 1 . In this case, the gripper 3 is attached near the front end 4 of the rapier 1, where the wear element 20 is also fitted. FIG. 4 shows a section at the tongue 11 and the recess 21 of the rigid top 10 and shows how the wear element 20 is guided by the guide hook 5 . Such a guide hook 5 is described in more detail in WO2006 / 037619. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com