Brewing type soybean milk machine for preventing dropping liquid

A soymilk machine and anti-drip technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of residue, dripping, user inconvenience, etc., achieve a simple and smooth pulp outlet, overcome hygienic dead corners, and facilitate cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

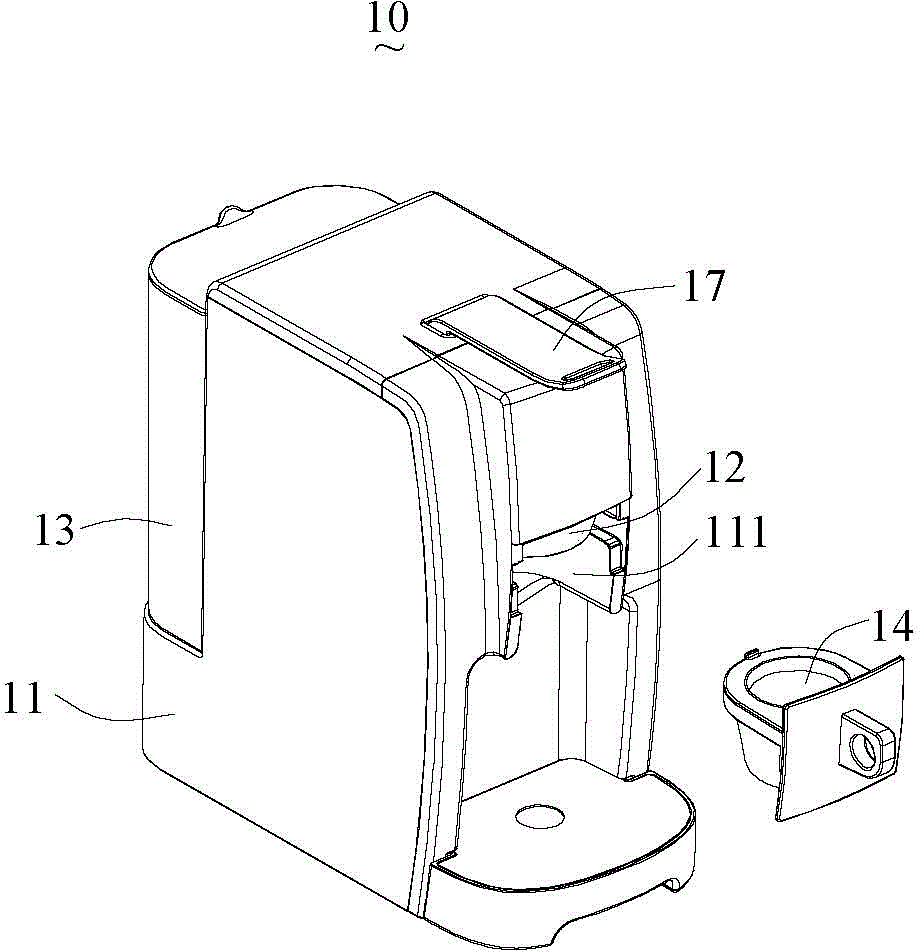

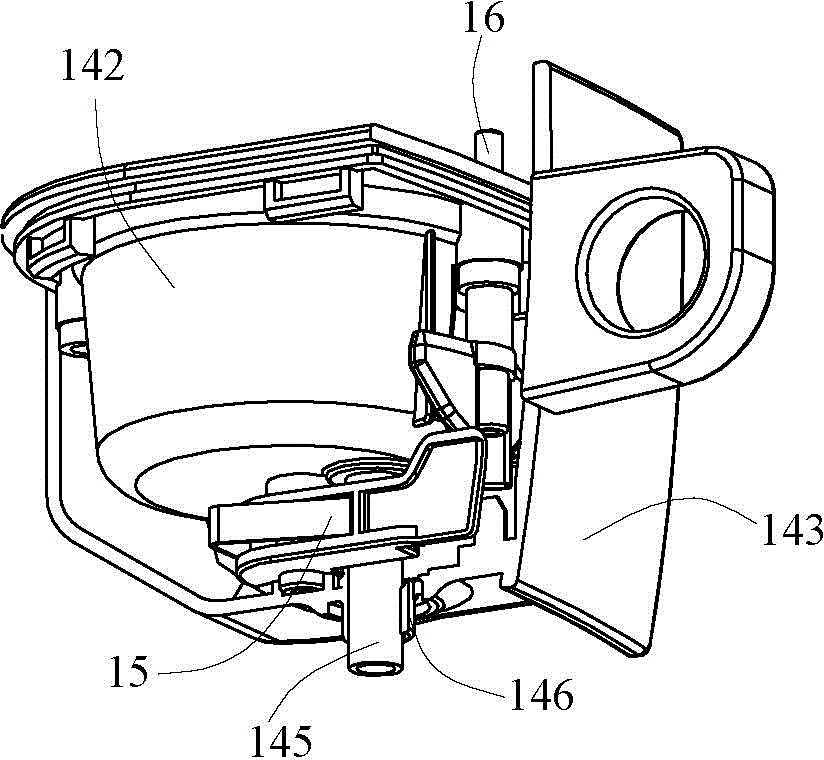

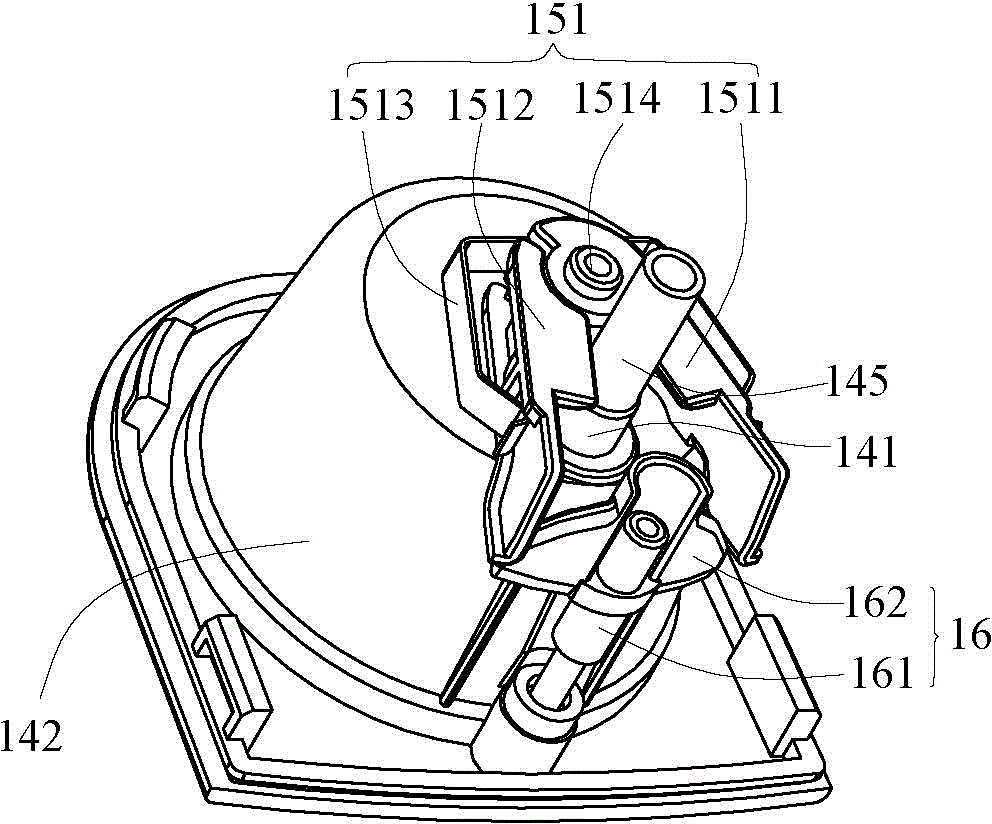

[0035] Please also refer to figure 1 , figure 2 and image 3 Shown is the first preferred embodiment of the anti-drip brewing soybean milk machine of the present invention, the anti-drip brewing soybean milk machine 10 includes a base 11 with a brewing chamber 111, a brewing head 12, and a brewing head 12 A liquid supply mechanism 13 for providing liquid, and a brewing cup 14 for accommodating a bag. The brewing head 12 moves towards or away from the brewing chamber 111 . The liquid supply mechanism 13 is arranged in the base 11 . The brewing cup 14 is freely inserted into or leaves the brewing cavity 111 of the machine base 11. The brewing cup 14 is provided with a slurry outlet channel 141 for the slurry to flow out. The slurry outlet channel 141 is provided with an opening and closing slurry outlet channel. The valve device 15, the brewing cup 14 is provided with a transmission mechanism 16 for driving the valve device 15 to open.

[0036] The machine base 11 is provi...

Embodiment approach 2

[0050] Please also refer to Figure 4 and Figure 5 The second preferred embodiment of the anti-drip brewing soymilk maker of the present invention is shown. The difference between the anti-drip brewing soymilk maker 20 and the anti-drip brewing soymilk maker 10 is that the rotating shaft 21 is set on the first clamping arm 22 and the middle part of the second clamping arm 23, the first clamping arm 22 and the second clamping arm 23 are arranged crosswise, the first clamping arm 22 and the second clamping arm 23 include a clamping end and an abutting end, and the abutting end The opening or tightening of the holding end drives the holding end to open and close the slurry outlet channel. The elastic member is a spring 24, and the two ends of the spring 24 are respectively fixed on the clamping ends of the first clamping arm 22 and the second clamping arm 23. end, the spring 24 provides clamping force for the first clamping arm 22 and the second clamping arm 23 . The transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com