Independent suspension drive axle housing assembly for heavy-duty truck

A technology of independent suspension and drive axle housing, which is applied to axles, wheels, vehicle parts, etc., and can solve the problems of complex casting process and difficult manufacturing of axle housings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

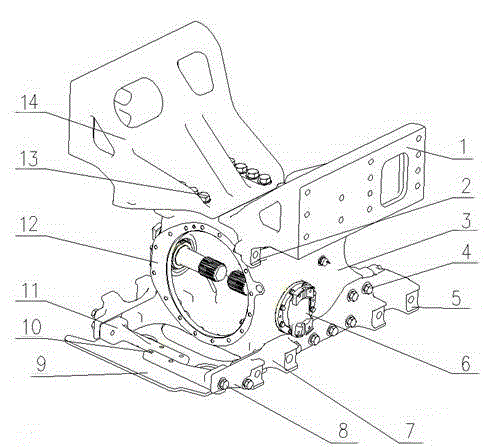

[0014] In order to clearly illustrate the technical characteristics of the solution, the following describes the solution through specific implementations and the accompanying drawings.

[0015] A heavy-duty vehicle independent suspension drive axle housing assembly, such as figure 1 As shown, it includes an axle housing 3 and a half shaft 6 arranged thereon. The half axles 6 are symmetrically arranged on two sides of the axle housing 3. The upper end of the axle housing 3 is fixedly connected with two symmetrically arranged upper brackets 14 through connecting bolts 13. The upper bracket 14 is provided with a frame mounting end surface 1 and a suspension upper swing arm mounting end surface 2; the lower end of the axle housing 3 is connected through The bolts 4 are fixedly connected with two symmetrically arranged lower brackets 7, and the lower bracket 7 is provided with two sets of suspension arm mounting end faces 5; the ends of the two lower brackets 7 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com