Carrying apparatus and composition of carrying apparatus and carried subject

A technology for carrying devices and loaded objects, which is applied to the types of packaging items, special packaging items, packaging, etc., and can solve the problems of wasteful use of box space, poor use, and cumulative thickness not as good as the box body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

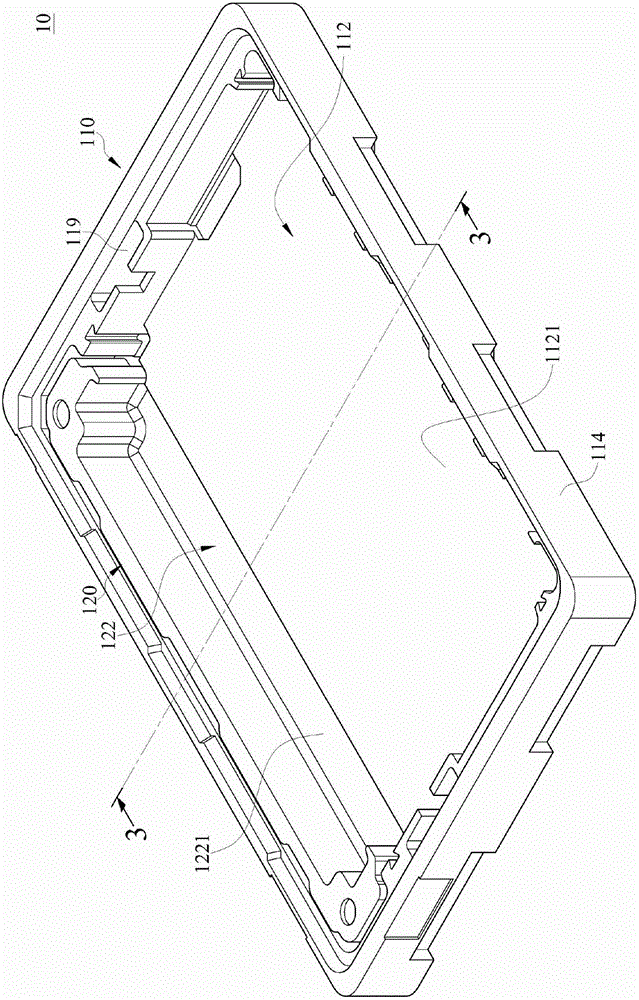

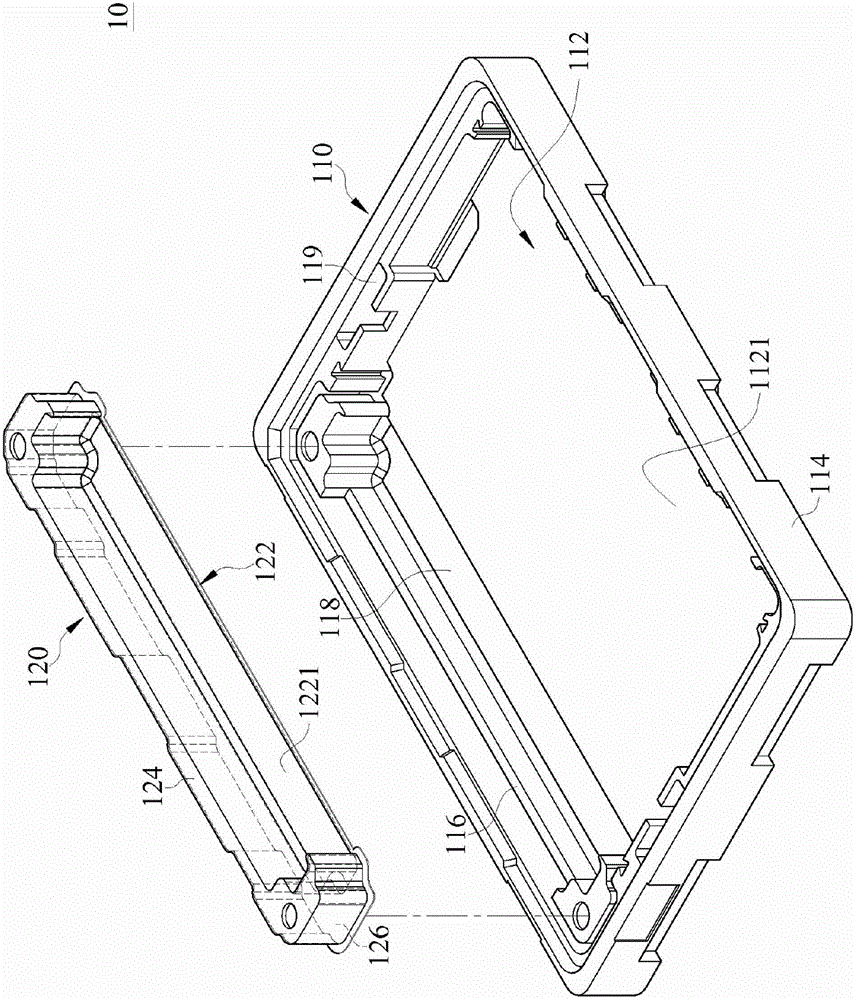

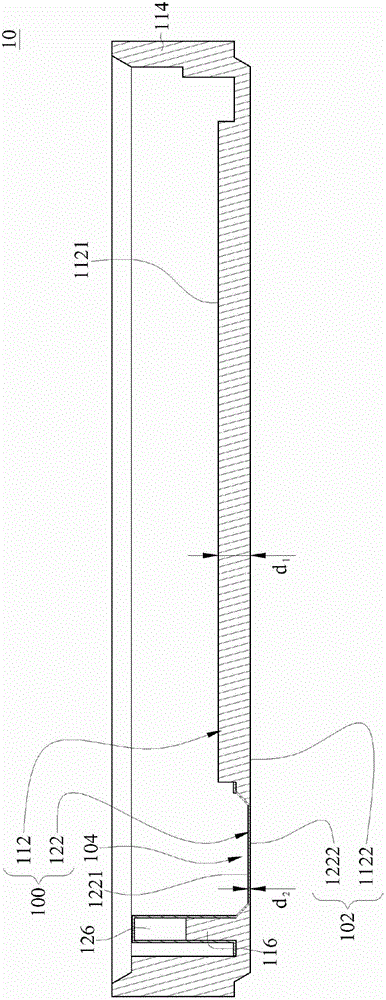

[0020] Please refer to Figure 1 to Figure 3 , figure 1 is a structural perspective view of a carrying device according to an embodiment of the present invention, figure 2 based on figure 1 The exploded view of the structure of the carrying device, image 3 based on figure 1 The structural cross-sectional view of the carrying device on the 33-section line.

[0021] The carrying device 10 of this embodiment is suitable for carrying the semi-finished display panel glass as a packaging material for the semi-finished display panel glass, but the application field of the carrying device 10 is not intended to limit the present invention.

[0022] The carrying device 10 includes a first body 110 and a second body 120 . The first main body 110 includes a first supporting board 112 and an annular side wall 114 surrounding the first supporting board 112 . The first carrying board 112 has a first bottom surface 1122 and a first carrying surface 1121 opposite to each other. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com