Multi-stage runner type waste water treating device and waste water treating method

A waste water treatment, flow channel technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problem, to achieve the effect of low cost of electrode materials, reduced processing cost, and increased oxidation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

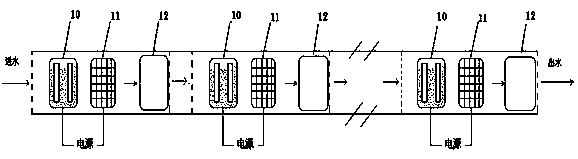

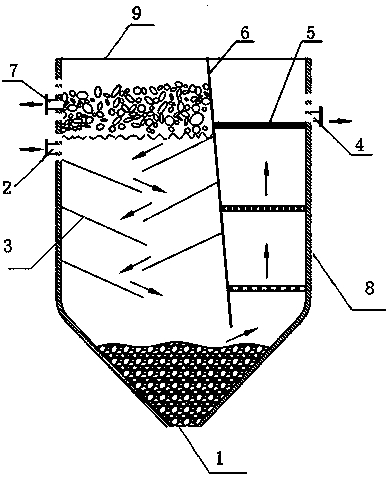

[0051] A multi-stage flow channel type wastewater treatment device is designed. The device includes an open channel in which multi-stage treatment units are arranged in sequence. After the wastewater is introduced, it is degraded and separated when flowing through the treatment units; the treatment unit consists of "Anode 10, cathode 11, oil-water slag separator 12", (1) The anode 10 is a nylon mesh frame filled with large particles of activated carbon and a catalyst. The catalyst is composed of platinum-plated black iron nails and discarded small iron Block (size not more than 1cm 3 ) Composition, the content of which is 15% of the mass of activated carbon, and the particle size of activated carbon particles is 30 mesh), the wire drawn from carbon rod or metal in the middle is connected to the positive pole of the power supply; (2) The cathode 11 is made of stainless steel mesh and connected to the power supply Negative (see attached figure 1 ). (3) The oil-water residue sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com