Quantum dot fluorescent anti-counterfeiting paper and manufacturing method thereof

A manufacturing method, quantum dot technology, applied in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve the problems of only a few minutes of excitation and emission cycle, easy overlapping of emission spectra, insufficient stability of fluorescent molecules, etc., to achieve good photochemical Stability, stable fluorescent anti-counterfeiting effect, good first-line anti-counterfeiting features and effects of second-line anti-counterfeiting features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a quantum dot fluorescent anti-counterfeiting paper, which is prepared through the following steps:

[0040]1. Process the cotton fiber into a length of 1mm-3mm, soak it into the quantum dot fluorescent material solution with a concentration of 2-5mg / mL for physical penetration, and control the soaking time for 15-30min. The quantum dot is based on CdSe as the core and ZnS is a core-shell structure nanobody with a shell size of 5nm, and the emitted light is yellow-green fluorescence with a wavelength of 520nm;

[0041] 2. After the quantum dot fluorescent material has fully penetrated into the cotton fiber, take it out for use;

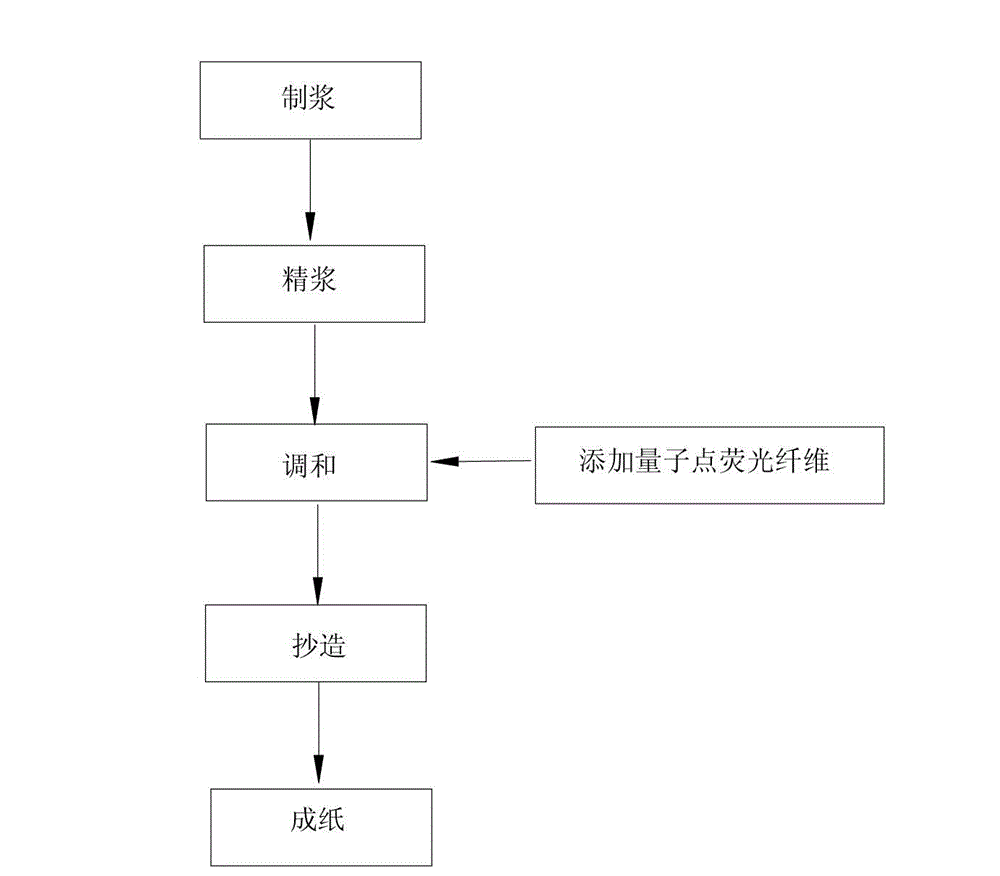

[0042] 3. In the process of papermaking, in the blending process, the cotton fibers infiltrated with quantum dot fluorescent materials are evenly dispersed in the pulp according to the ratio of 0.1%-0.2% of dry pulp (the process flow is as follows: figure 1 shown), uniformly and randomly applied to wet paper sheets, so...

Embodiment 2

[0051] This embodiment provides a quantum dot fluorescent anti-counterfeiting paper, which is prepared through the following steps:

[0052] 1. Process the cotton fiber into a length of 1mm-3mm, soak it into the solution of the first quantum dot fluorescent material with a quantum dot concentration of 2mg / mL in chloroform for physical infiltration, and control the soaking time to 15-30min. The quantum dot is based on The core-shell structure nanobody with CdSe as the core and ZnS as the shell has a size of 5nm and emits yellow-green fluorescence with a wavelength of 520nm;

[0053] 2. After the first quantum dot fluorescent material has completely penetrated into the cotton fiber, take it out, and then soak it into the second quantum dot fluorescent material solution with a quantum dot concentration of 5 mg / mL in toluene solution for physical infiltration. Quantum dots are nanobodies with a core-shell structure with CdSe as the core and ZnS as the shell. The size is 7nm, and t...

Embodiment 3

[0062] 1. Soak the polyvinyl alcohol film with a thickness of 30-100 μm (the area of the film has no clear requirements, it can be determined according to the amount of quantum dots and the size of the dyeing container, and the polyvinyl alcohol film can be reprocessed according to requirements after application) Physically infiltrate into the toluene solution of quantum dot fluorescent materials with a quantum dot concentration of 2-10mg / mL, and the soaking time is controlled at 15-30min. The quantum dot is a core-shell nanobody with CdSe as the core and ZnS as the shell. , the size is 5nm, and the emitted light is yellow-green fluorescence with a wavelength of 520nm;

[0063] 2. After the quantum dot fluorescent material has completely penetrated into the interior of the polyvinyl alcohol film, take it out, cut it into a predetermined shape, and set it aside;

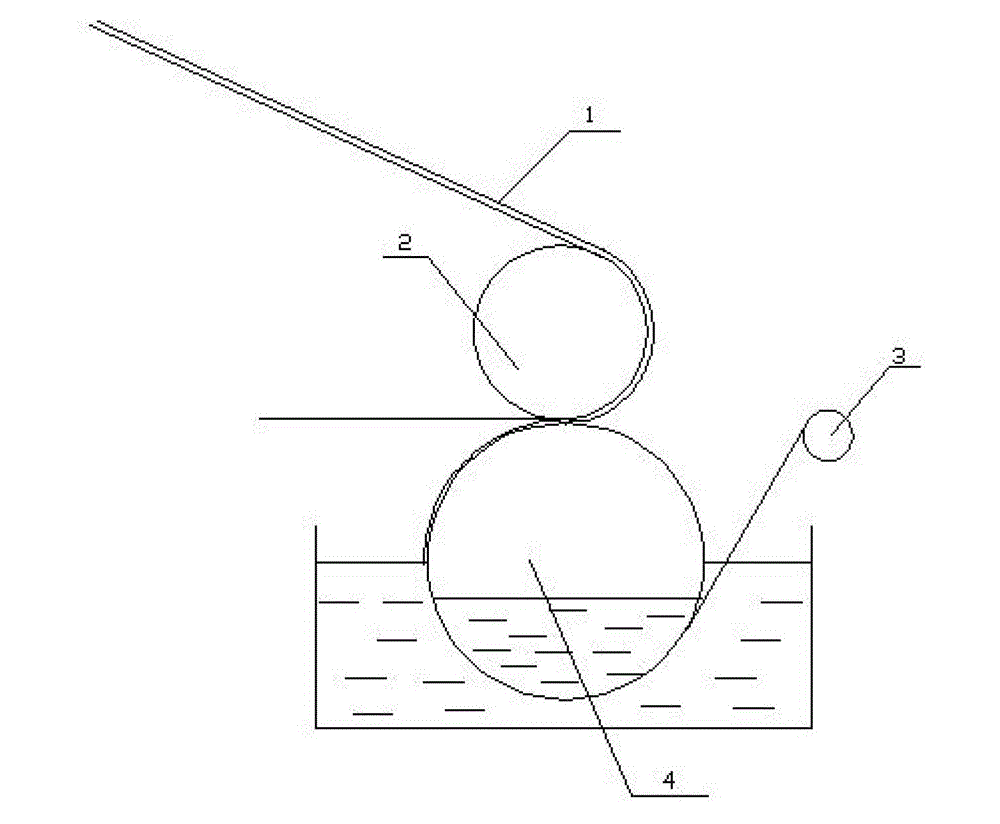

[0064] 3. In the process of paper making, first make a layer of wet paper, and apply a polyvinyl alcohol film cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com