Anti-counterfeiting pigment as well as preparation method and application thereof

A kind of pigment, fluorescent dye technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of anti-counterfeiting pigment, its preparation method comprises the following steps:

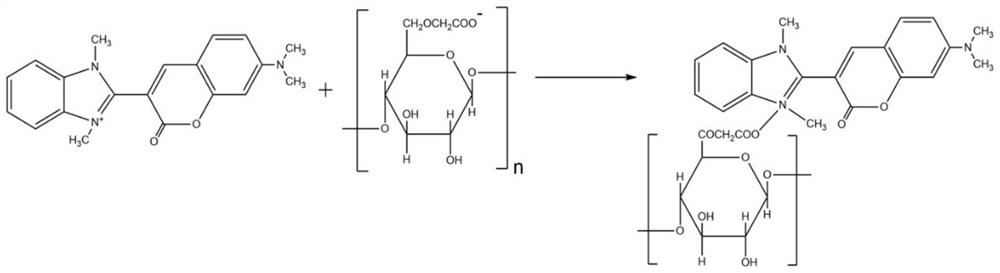

[0040] 1) Add 0.30 g of microcrystalline cellulose and 0.06 g of fluorescent yellow to 600 mL of deionized water, and stir for 65 min at a rotating speed of 3200 r / min under dark conditions to obtain a mixed dispersion (microcrystalline cellulose and fluorescent yellow). The schematic diagram of the self-assembly reaction process is shown in figure 1 shown);

[0041] 2) Add 1.65 g of rosin-modified phenolic resin (analytical grade, Sinopharm Chemical Reagent Co., Ltd.) into the reactor equipped with a mechanical stirring rod, stir continuously at a rotating speed of 6200 r / min, and heat up to 190 ° C, then add Mix the dispersion, 0.02g of hyperdispersant SRE-47000-100HB (Guangdong Fuji Technology Co., Ltd.) and 0.02g of light stabilizer Tinuvin326 (BASF, Germany), continue to stir for 100min, cool to 38°C and filter, and the filtered solid Washing with hot water, then drying...

Embodiment 2

[0043] A kind of anti-counterfeiting pigment, its preparation method comprises the following steps:

[0044] 1) Add 0.38 g of microfibrillated cellulose and 0.075 g of rhodamine B to 607 mL of deionized water, and stir for 55 min at a rotating speed of 3800 r / min under dark conditions to obtain a mixed dispersion;

[0045] 2) Add 1.50 g of rosin-modified phenolic resin (analytical grade, Sinopharm Chemical Reagent Co., Ltd.) into the reactor equipped with a mechanical stirring rod, stir continuously at a rotating speed of 6200 r / min, and heat up to 160 ° C, then add Mix the dispersion, 0.03g of hyperdispersant SRE-47000-100HB (Guangdong Fuji Technology Co., Ltd.) and 0.03g of light stabilizer Tinuvin326 (BASF, Germany), continue to stir for 130min, cool to 38°C and filter, and the filtered solid Washing with hot water, then drying in a vacuum drying box at 95°C for 4.5 hours, and pulverizing to obtain an anti-counterfeiting pigment.

Embodiment 3

[0047] A kind of anti-counterfeiting pigment, its preparation method comprises the following steps:

[0048] 1) Add 0.28 g of bacterial cellulose and 0.065 g of basic brilliant blue to 539 mL of deionized water, and stir at a speed of 3200 r / min for 65 min under dark conditions to obtain a mixed dispersion;

[0049] 2) Add 1.56 g of rosin-modified phenolic resin (analytical grade, Sinopharm Chemical Reagent Co., Ltd.) into the reactor equipped with a mechanical stirring rod, stir continuously at a rotating speed of 6600 r / min, and heat up to 160 ° C, then add Mixed dispersion, 0.025g of hyperdispersant SRE-47000-100HB (Guangdong Fuji Technology Co., Ltd.), 0.02g of light stabilizer Tinuvin326 (BASF, Germany) and 0.01g of surfactant Dowfix2A1 (Dow Chemical Company, USA), Continue stirring for 100 min, cool to 30°C and filter, wash the filtered solid with hot water, then place it in a vacuum drying oven at 85°C to dry for 5.5 hours, and pulverize to obtain an anti-counterfeiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com