Dragline buttress steel dam

A steel structure dam and buttress technology, applied in the direction of buttress dams, dams, sea area engineering, etc., can solve the problems of outstanding stability of steel structure dams, difficulty in meeting the stress and deformation control requirements of the dam body, and achieve simple and reliable structure The effect of flexible connection and hub arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

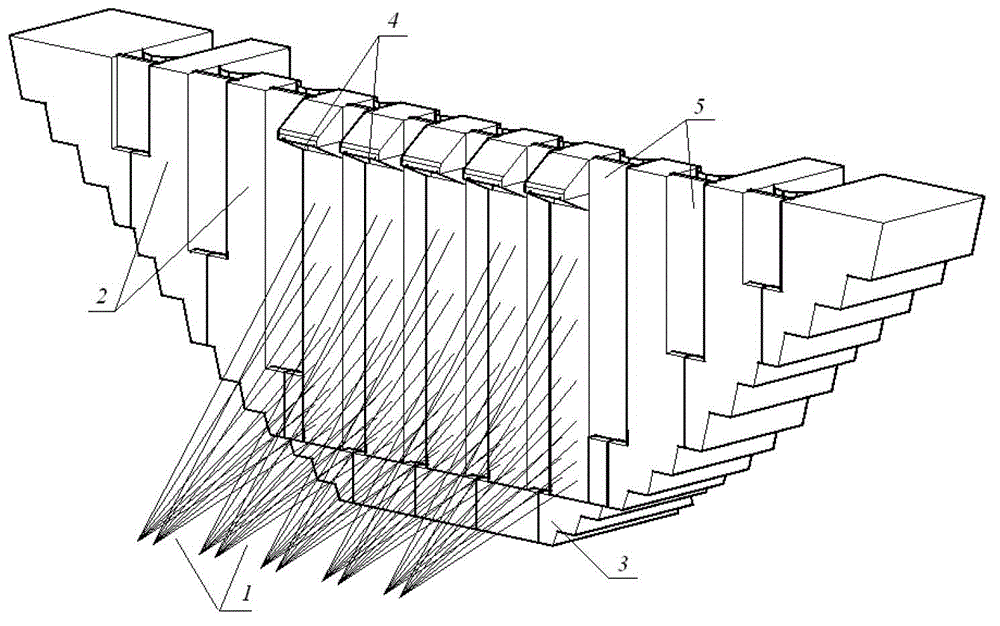

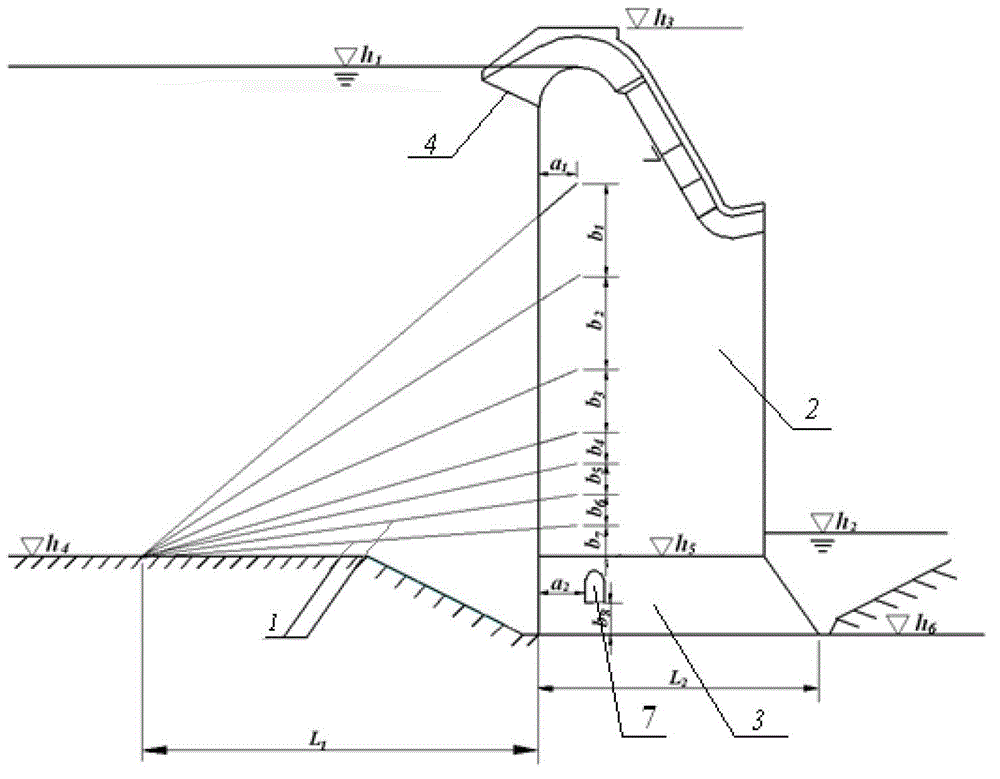

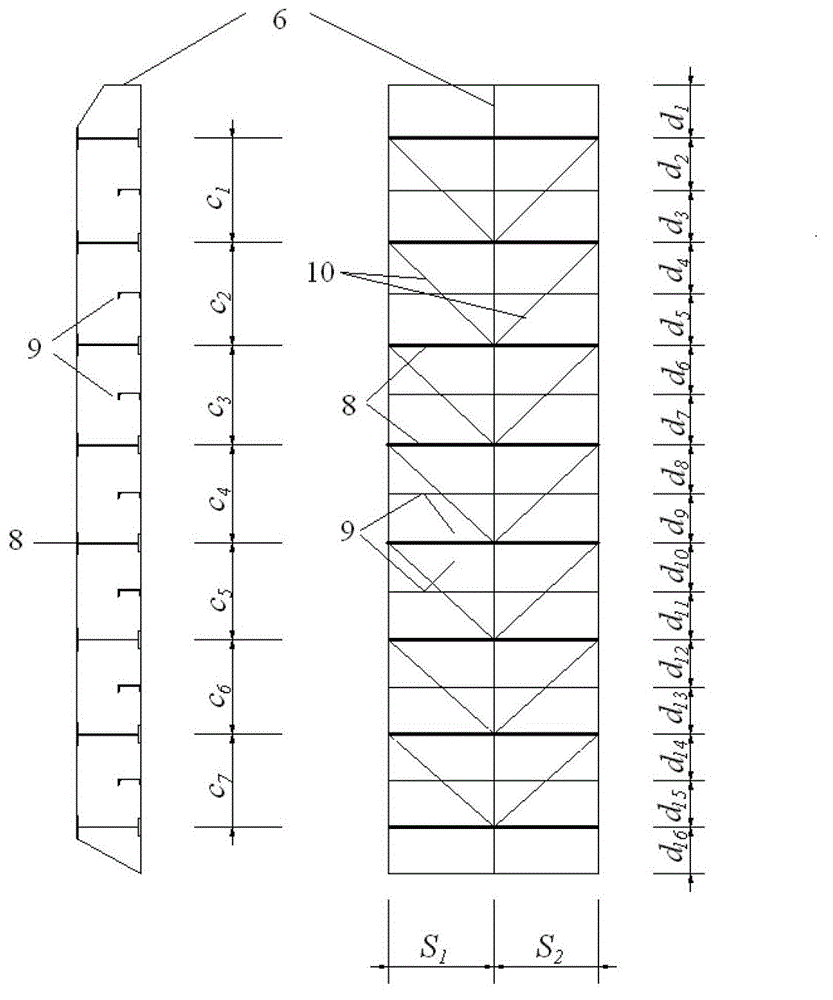

[0024] The steel structure dam with cable buttress is mainly composed of two parts: one is the cable buttress supporting the steel structure panel, its main function is to fix and restrain the steel structure, and transmit the huge water thrust formed by the steel structure to the The foundation is used to maintain the stability of the entire dam body. In addition, the pier structure can also be equipped with a drainage system to discharge excess water. The second is the steel structure panel mainly composed of beams, partitions, panels, etc., and its main function is to retain water. In addition, concrete pedestals are included, whose main function is to connect the steel structure to the foundation. The specific instructions are as follows:

[0025] Such as figure 1 As shown, the overall structure of the cable-supported steel dam of the present invention includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com