Fan module testing system

A technology for testing systems and fan modules, applied in pump testing, liquid variable capacity machinery, pump control, etc., can solve problems such as the inability to finely adjust the fan speed and affect the accuracy of fan module testing, and achieve the goal of improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

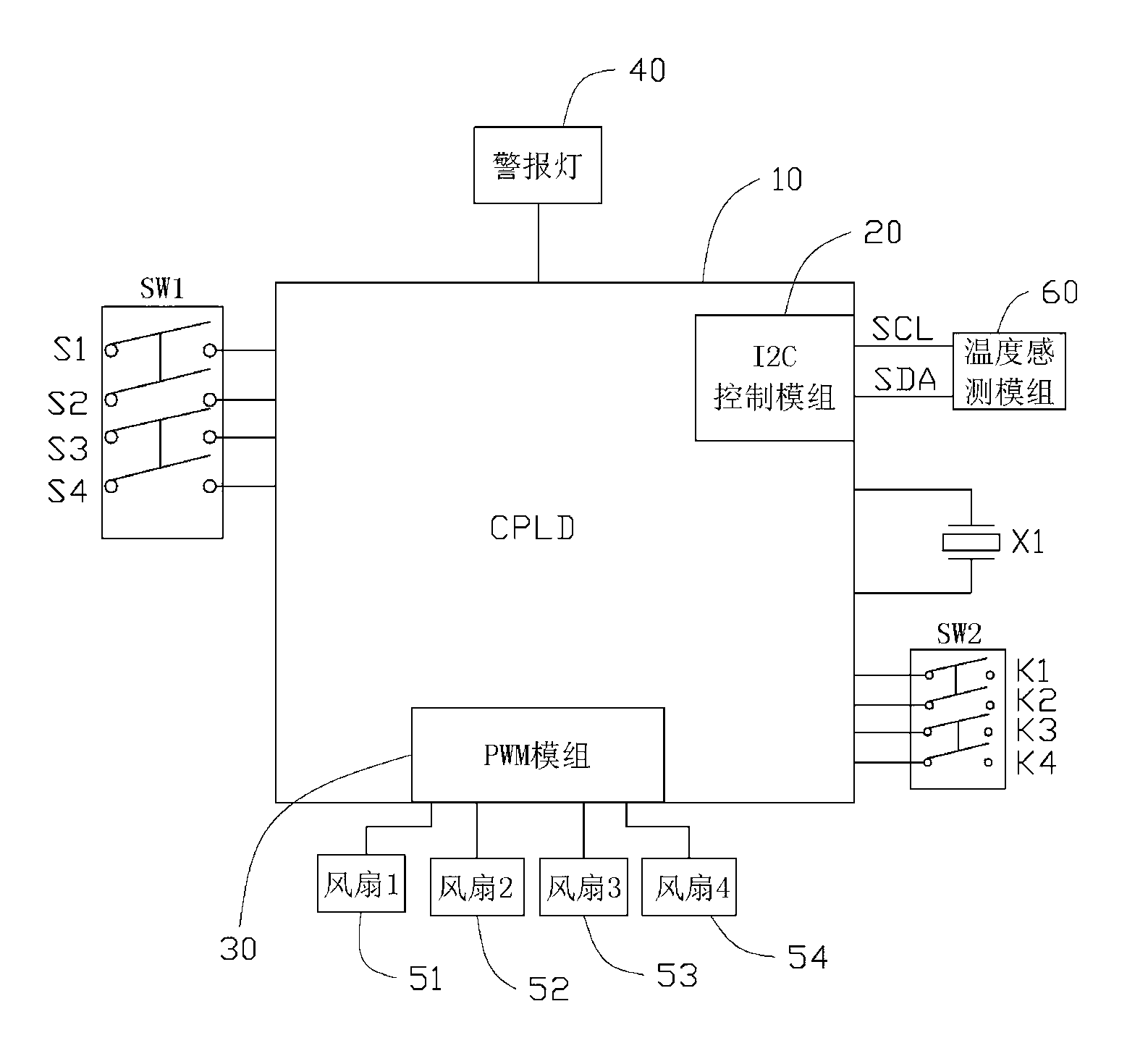

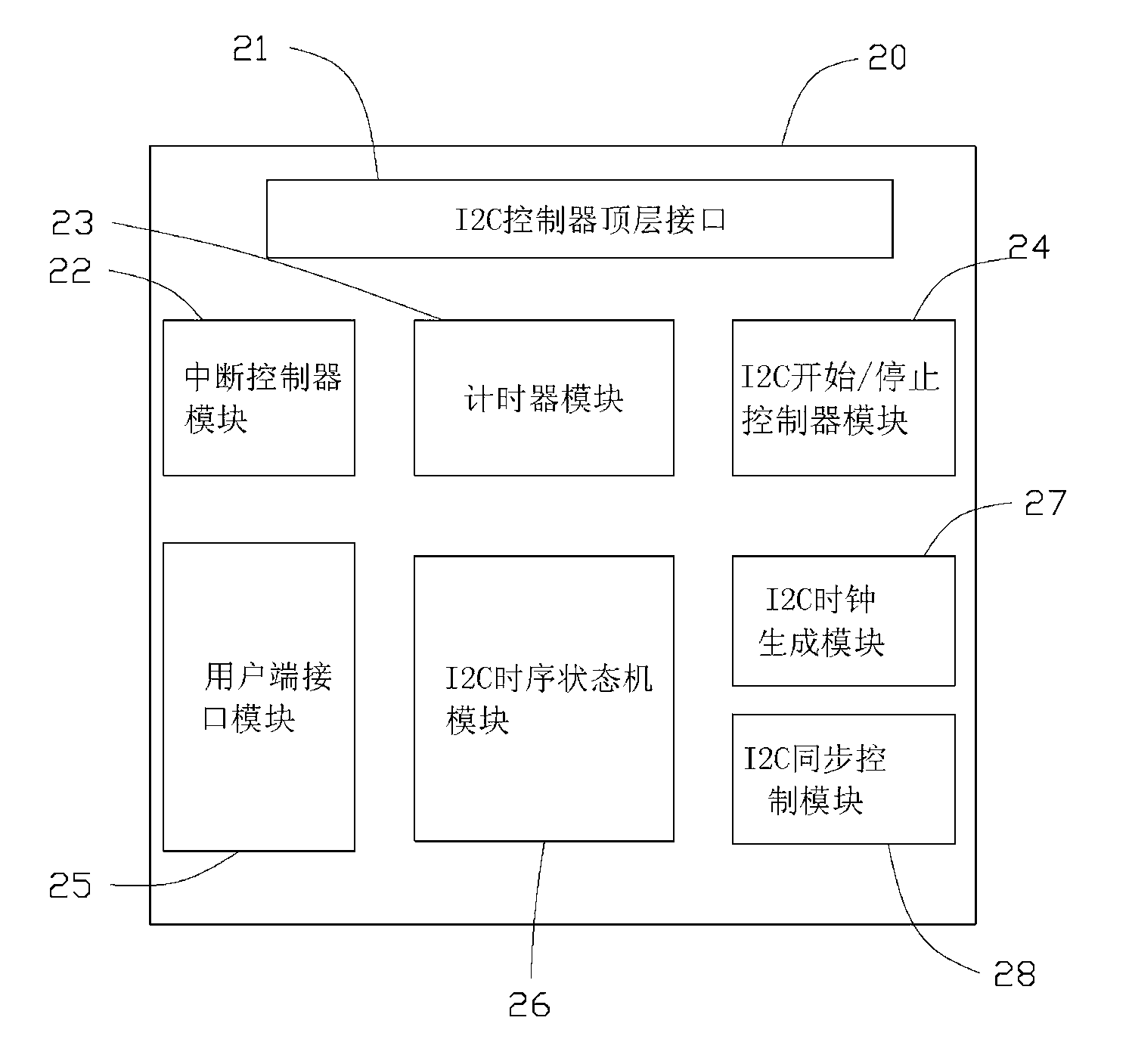

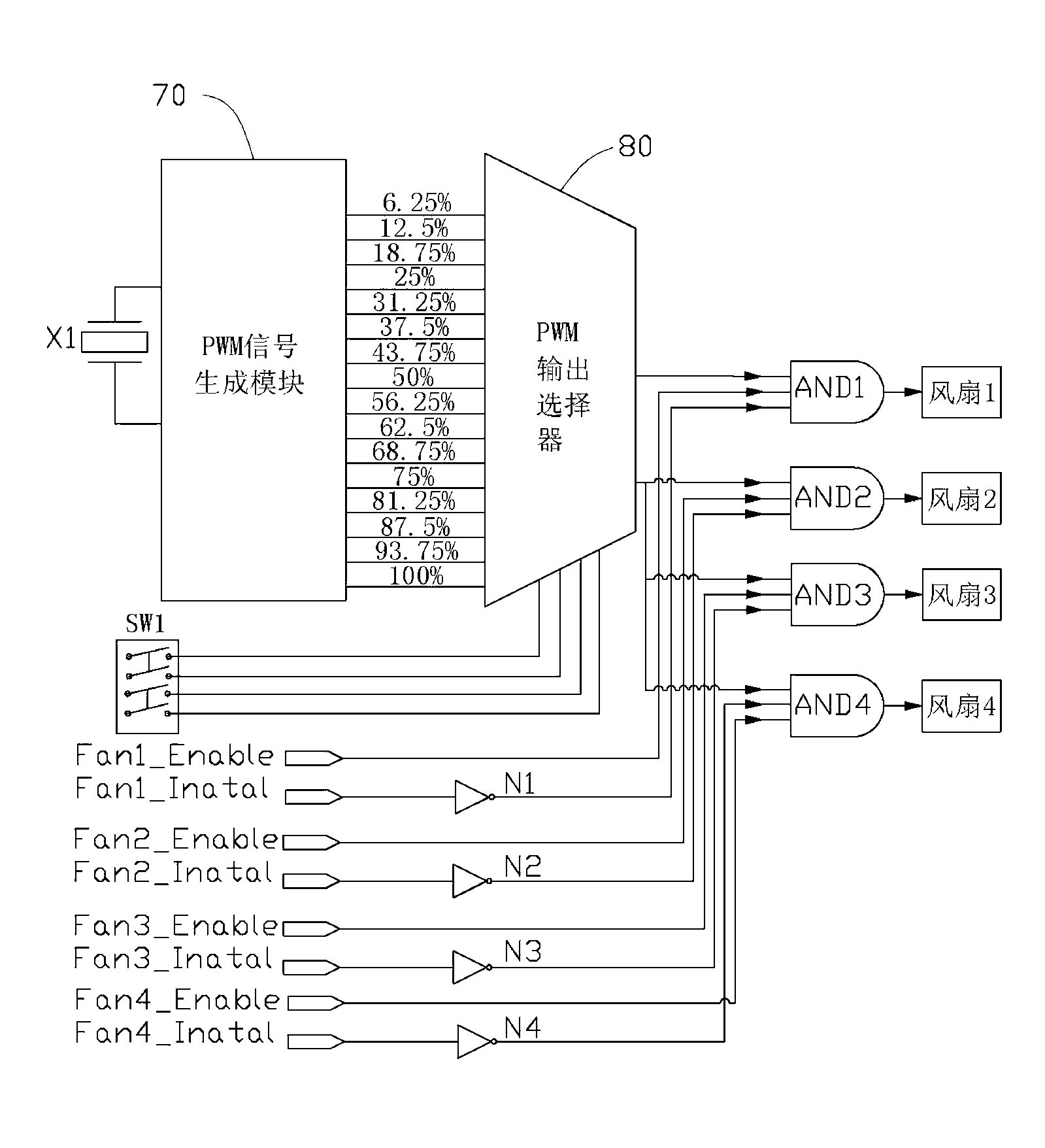

[0012] see figure 1 , the preferred embodiment of the present invention fan module test system includes a CPLD (Complex Programmable Logic Device, complex programmable logic device) 10, the CPLD 10 is externally connected with a first switch module SW1, a second switch module SW2, A crystal oscillator X1 for generating an external clock signal, an alarm light 40, a temperature sensing module 60 and a plurality of fans. The plurality of fans include a first fan 51 , a second fan 52 , a third fan 53 and a fourth fan 54 . The CPLD 10 includes an I2C (a serial communication bus) control module 20 and a PWM (Pulse Width Modulation, pulse width modulation) module 30 . The PWM module 30 is connected to the first fan 51 , the second fan 52 , the third fan 53 and the fourth fan 54 to output PWM signals to control the speeds of these fans. The I2C control module 20 includes a serial clock line SCL and a serial data line SDA, the serial clock line SCL and the serial data line SDA of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com