Connection joint for ensuring synchronous movement of rod pieces

A technology of connecting nodes and synchronizing motion, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of geometric constraint failure, singular motion, etc., and achieve the effect of compact connection, beautiful appearance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

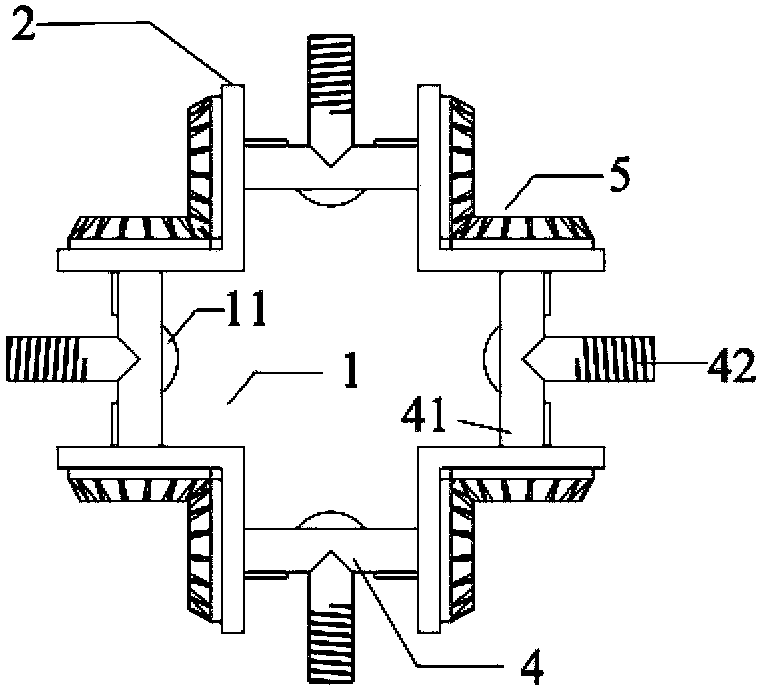

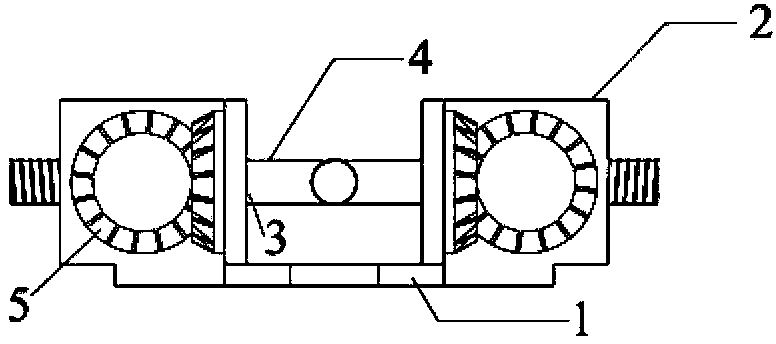

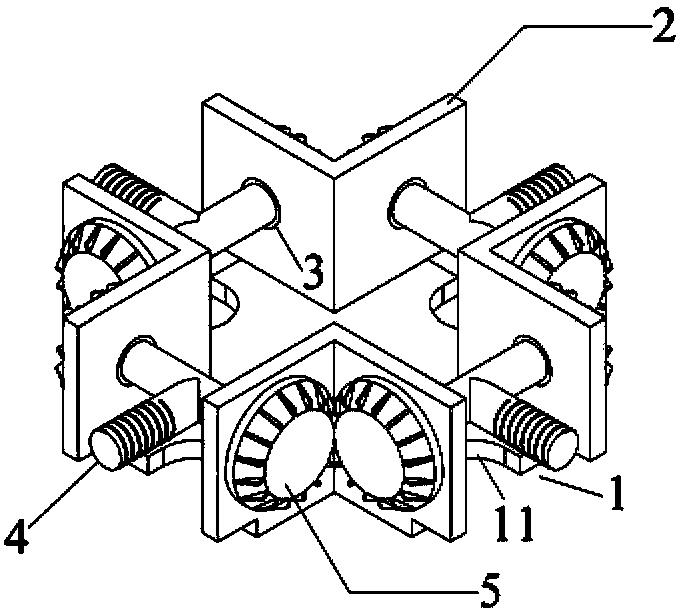

[0022] figure 1, figure 2 They are respectively a schematic diagram of the overall structure and a schematic diagram of the main components of the connection node for ensuring the synchronous movement of the rods in the present invention.

[0023] The connection node to ensure the synchronous movement of the rods of the present invention includes a base 1, N L-shaped plates 2, N T-shaped rotating shafts 4 and 2N bevel gears 5, wherein N is an integer greater than 2, and N L-shaped plates 2 is center-symmetrically arranged on one side of the base 1, and the T-shaped rotating shaft 4 is arranged between two adjacent L-shaped plates 2. The two bevel gears 5 adjacent to each L-shaped plate 2 mesh with each other.

[0024] In the present invention, the L-shaped plate 2 is formed by connecting two straight plates of equal length and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com