A conveying device for waste disposal

A technology of conveying device and garbage disposal, applied in the direction of garbage conveying, storage device, garbage collection, etc., can solve the problems of increasing equipment cost and occupying space and compressing the garbage disposal volume of equipment, so as to reduce impact, improve extrusion effect and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

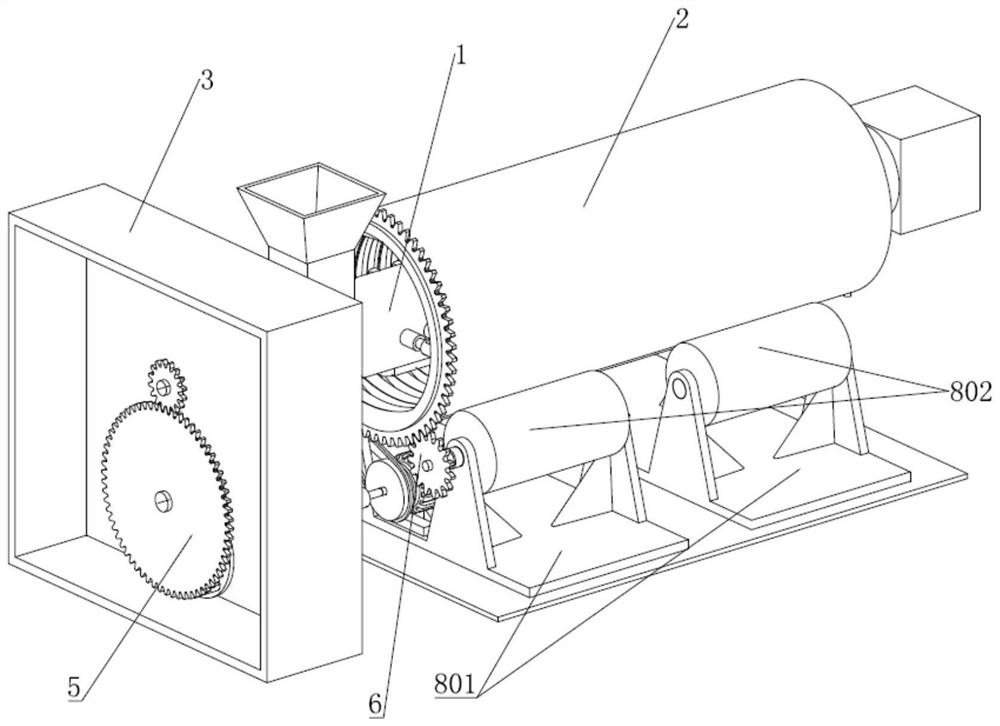

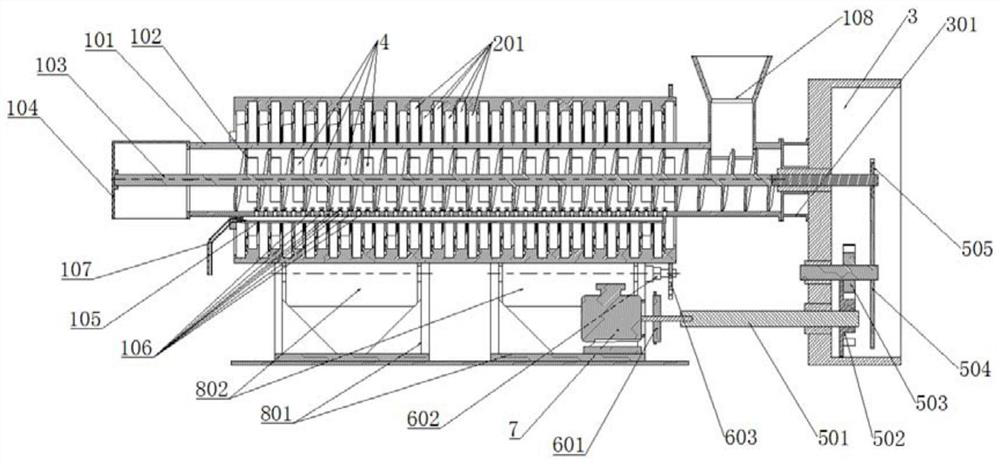

[0030] Such as Figure 1-5 with Figure 8-10 As shown, the present invention provides a conveying device for waste treatment, including a screw conveying mechanism 1, including a drive device 7, a conveying casing 101, and a helix disposed within the conveying cylinder 101 The conveying rod 103 is fixed to the helical transport rod 103, and the top of the conveying cylinder 101 is provided with a feed hopper 108, and the other end is provided with a discharge port 104.

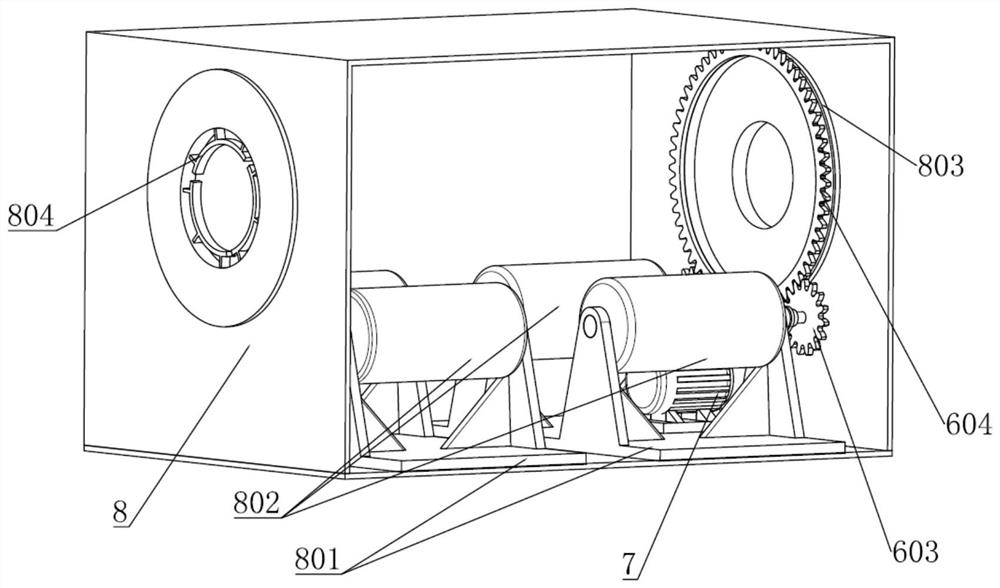

[0031]The conveying device further includes an outer extrusion sleeve 2, a pressure plate mechanism 4, a rotating mechanism, and a support housing 8, and the outer extrusion sleeve 2 is rotated in the support housing 8, the outer extrusion sleeve. The cartridge 2 concentric sleeve is outside the conveying cylindrical case 101 on the compression area of the conveying cylindrical case 101, the drive device 7 drives the outer extruded sleeve 2 by the transmission mechanism; the conveying cylinder housing 101 The side...

Embodiment 2

[0043] The basic structure of this embodiment is similar to that of Example 1, and the difference is that the spiral rod drive mechanism 5. Such as Figure 6-7 As shown, in the present embodiment, a pair of arc shaped extrudation portions, the arc shaped extrudation portion occupies a quarter arc portion of the outer extruded sleeve 2, The arc shaped extrusion portion is configured on the outer extrusion sleeve 2, the active sprocket 601 is equal to the radius of the outer ring gear 604, and the cylindrical pin 5022 is paired and symmetric is located in the On the dial 502, a pair of convex arc 5023 is provided on the dial 502, and the convex lock arc 5023 is a quarter arc and symmetrically disposed, and the transmission gear one 504 and the drive gear two. The speed ratio of 505 is 1: 4. The groove 503 is provided with four pile stopping arc 5032 corresponding to the convex arc 5023 to realize the stationary wheel 503 in the gap cycle. In this case, the conveying state is longer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com