Balance valve with separated valve body and valve seat

A technology of balancing valve and valve body, applied in the field of balancing valve, can solve the problems of poor preheating before welding and post-welding heat treatment, cracks on the sealing surface of cemented carbide surfacing welding, low grinding quality and efficiency of valves, etc., so as to shorten the maintenance period. time, reliable performance, improved labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

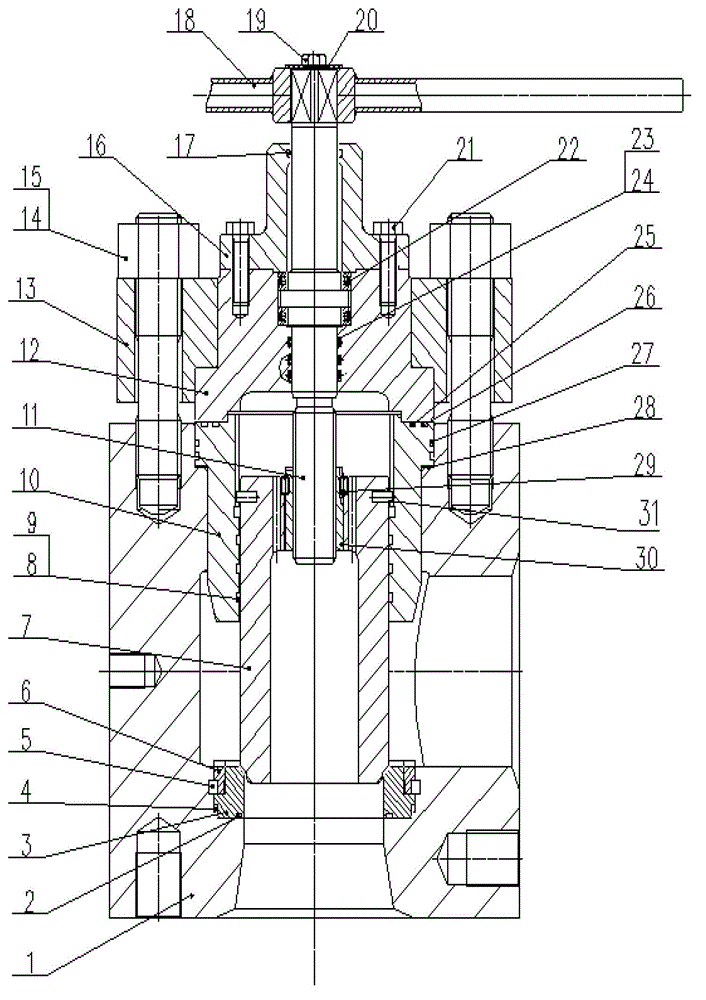

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

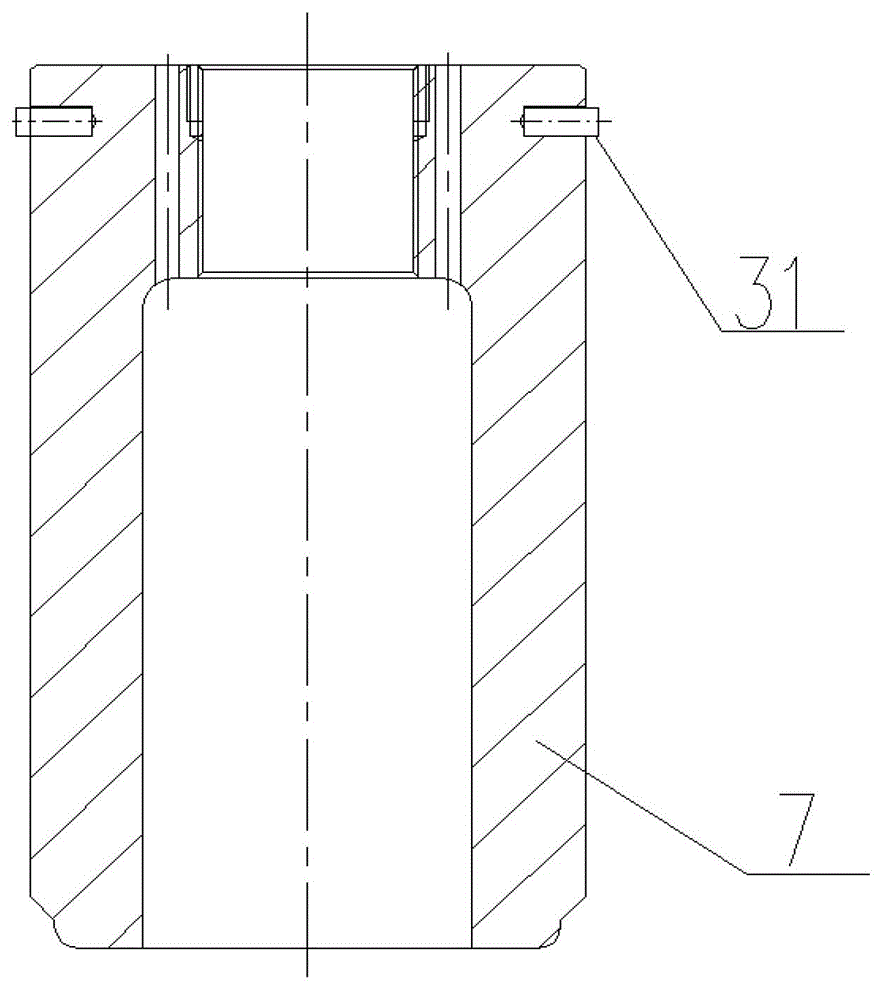

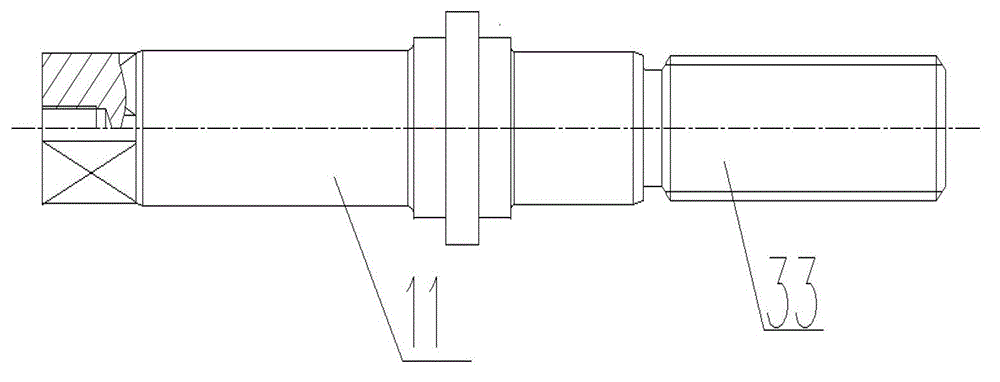

[0028] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the valve body 1 is located at the lowermost end of the entire balance valve. A detachable valve seat 3 is installed at the lower end of the inner cavity of the valve body 1. A bushing 6 is installed on the upper end of the outer surface of the valve seat 3. The outer surface of the bushing 6 The lower end of the Liuhe ring 5 is installed, one end of the Liuhe ring 5 is built in the valve body 1, the other end is in the bushing 6, the outer surface of the valve seat 3 is equipped with an O-ring 4, and the bottom surface of the valve seat 3 is installed with an O-ring. type sealing ring 2. The upper end of the inner cavity of the valve body 1 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com