Distributor and plate-fin heat exchanger with same

A technology for distributors and heat exchangers, which is applied in the field of distributors and heat exchangers with the distributors, can solve the problems of few dynamic studies on logistics distribution rules, improve anti-sloshing performance, avoid gas-liquid stratification, The effect of solving the problem of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

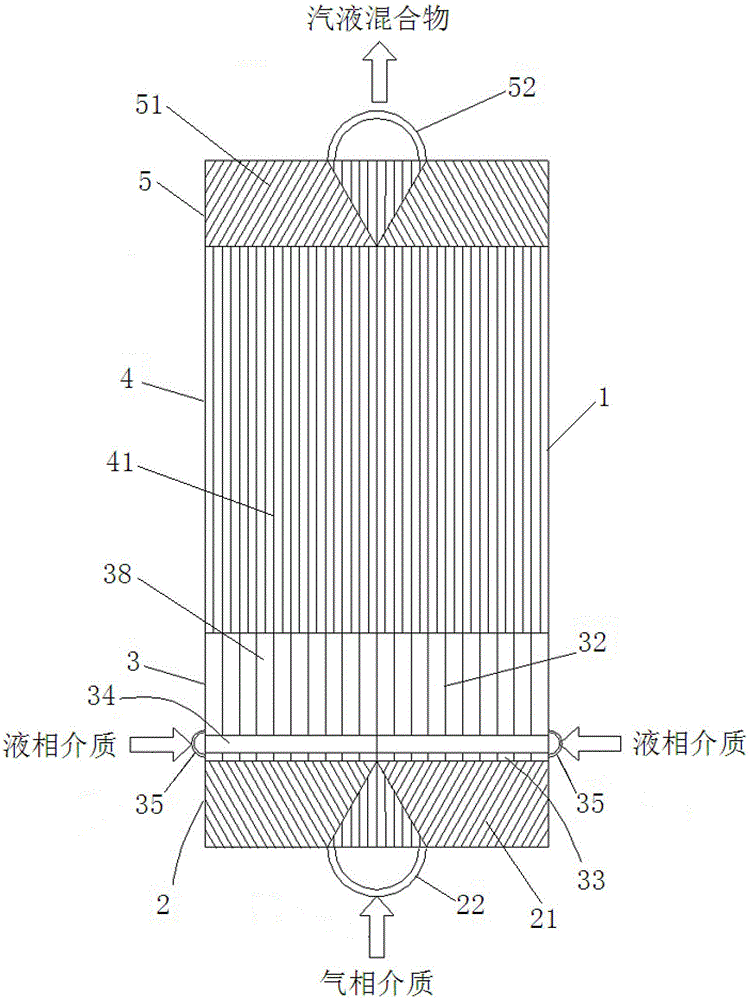

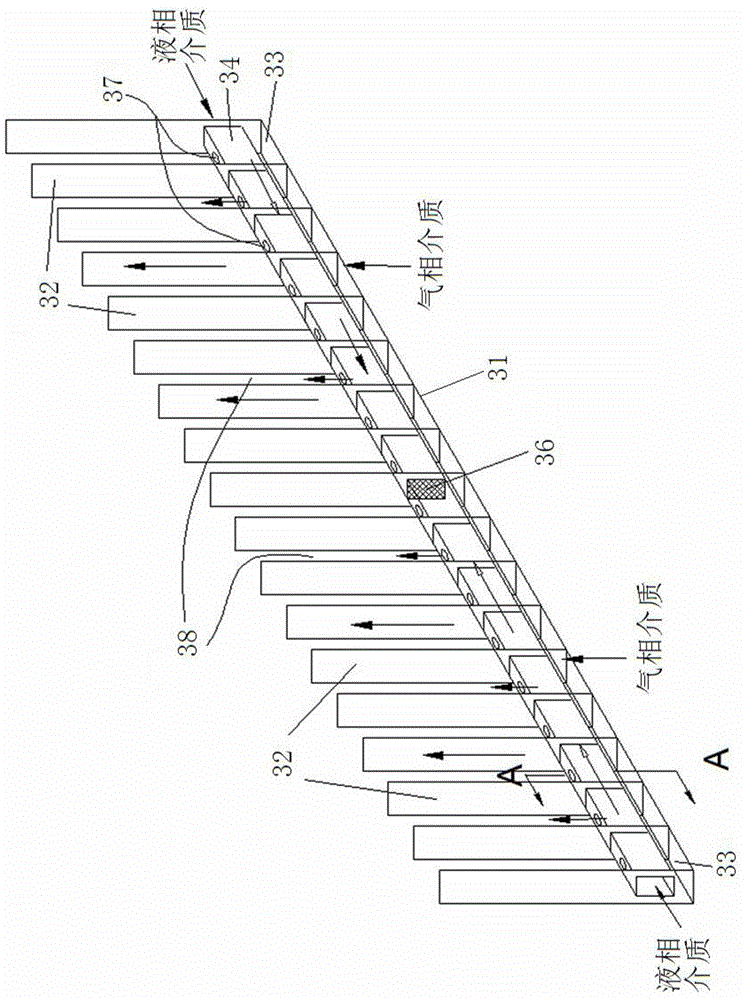

[0013] Such as figure 1 As shown, the present invention includes a heat exchanger shell 1, and the inside of the heat exchanger shell 1 is sequentially arranged as a gas phase flow guide area 2, a distribution area 3, a fin area 4 and a gas-liquid mixing flow guide area 5.

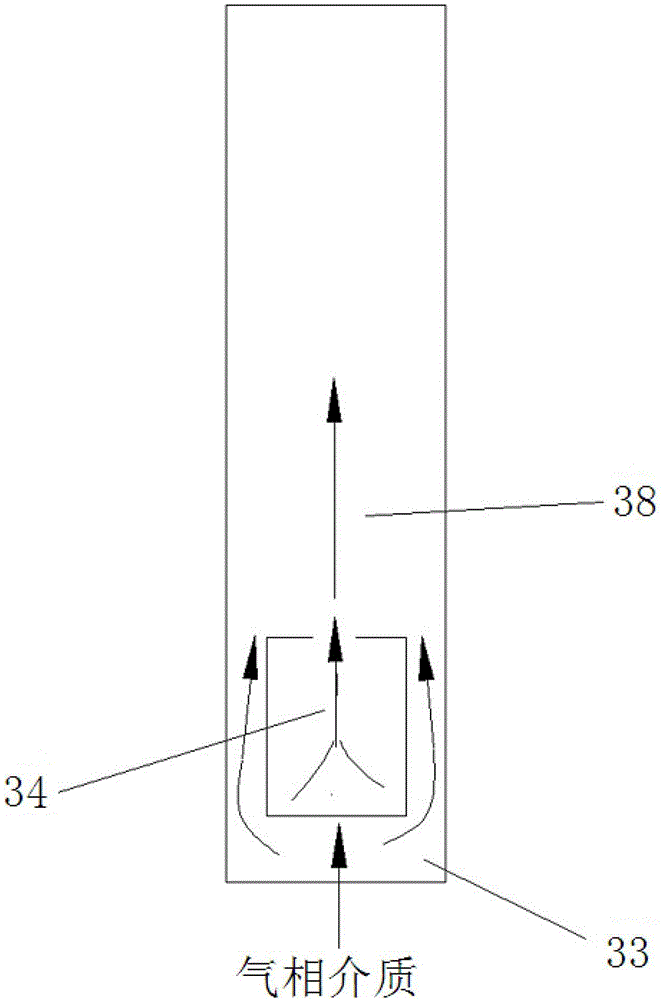

[0014] Such as figure 1 As shown, a wave-shaped gas-phase medium deflector 21 is arranged in the gas-phase diversion area 2, and a gas-phase inlet is arranged at the middle of the bottom of the heat exchanger shell 1 where the gas-phase diversion area 2 is located, and a gas-phase inlet is arranged outside the gas-phase inlet. The inlet head 22 is opened, the gas phase inlet head 22 is opened, the gas phase medium enters the gas phase guide area 2 through the gas phase inlet, and the gas phase medium enters the distribution area 3 through the action of the gas phase medium guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com