Calibrating method of electrolyte analyzer

An electrolyte analyzer and calibration technology, applied in the direction of material analysis, material analysis by electromagnetic means, instruments, etc., can solve problems such as cross-contamination, accuracy and real-time performance cannot be guaranteed, and the amount of electrode drift fluid used is large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

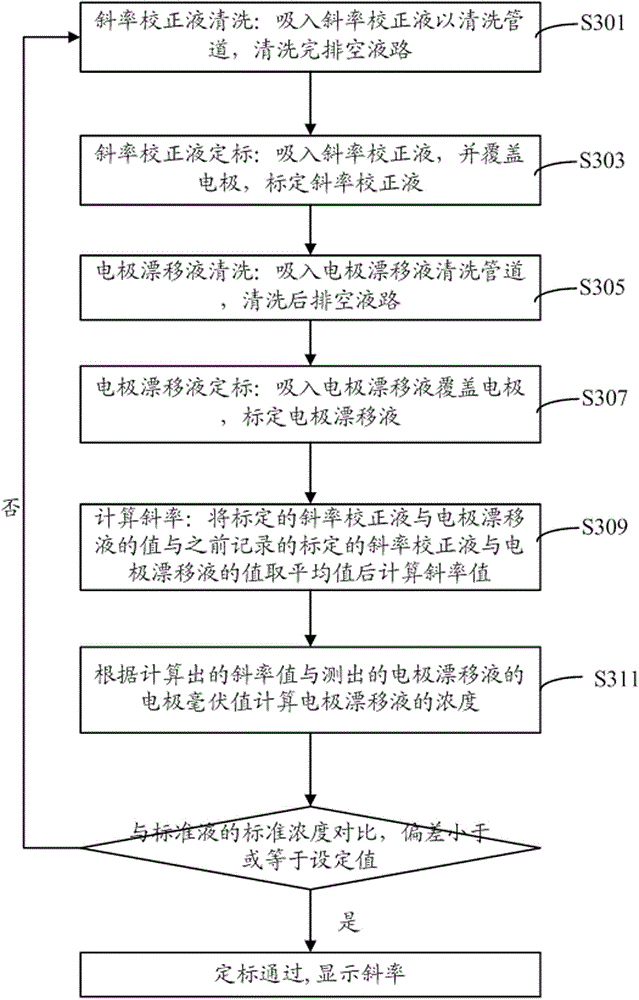

[0034] Such as figure 1 As shown, the calibration method of the electrolyte analyzer of an embodiment of the present invention includes:

[0035] Step S301, cleaning the slope correction fluid: inhaling the slope correction fluid to clean the pipeline, and emptying the fluid path after cleaning.

[0036] Step S303, calibrate the slope correction solution: absorb the slope correction solution, cover the electrodes, and calibrate the slope correction solution.

[0037] Furthermore, the process of calibrating the slope correction liquid in this embodiment is mainly the process of measuring the millivolt value measured by the corresponding ion electrode when the slope correction liquid enters the electrode.

[0038] Step S305, cleaning the electrode drift liquid: inhaling the electrode drift liquid to clean the pipeline, and emptying the liquid path after cleaning.

[0039] Step S307, calibrate the electrode drift liquid: absorb the electrode drift liquid to cover the electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com