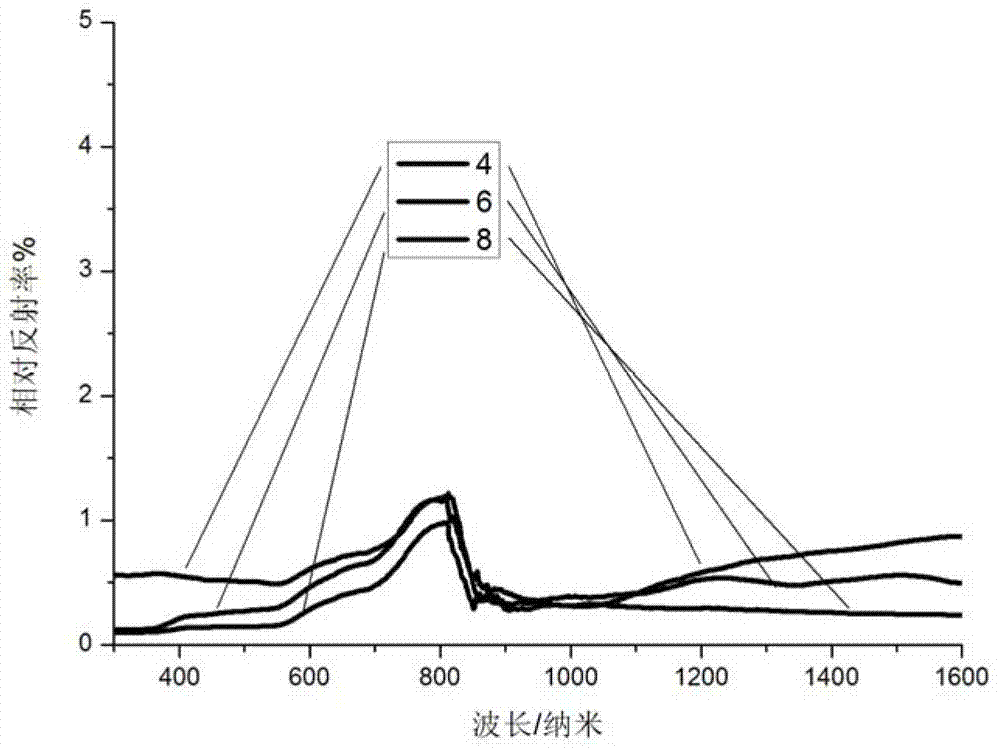

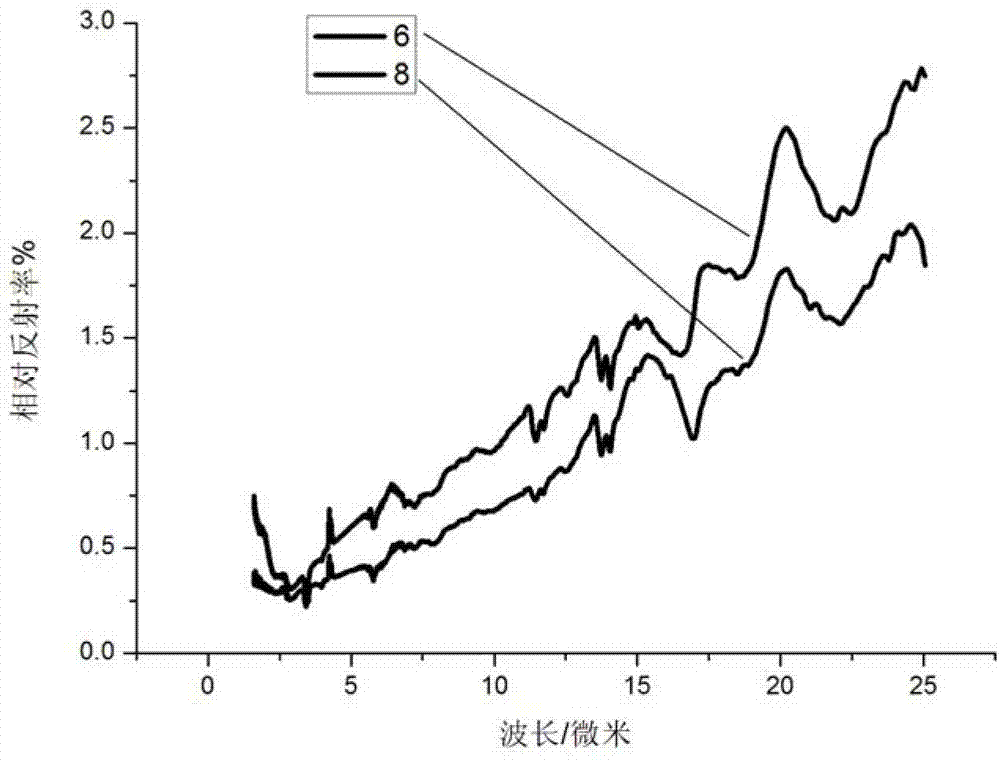

Low-cost coating with self-cleaning and infrared broadband hiding functions, preparation method and application of coating

A self-cleaning, dual-function technology, applied in electrical components, antennas, etc., can solve the problems of inability to achieve broadband stealth, stealth materials do not have self-cleaning functions, etc., to achieve a wide range of practical promotion value, strong repairability, expansion Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Immerse the galvanized engineering material tinplate in a 4mol / L hydrogen ion hydrochloric acid solution for 30 seconds, then take out the corroded galvanized engineering material, rinse it repeatedly with deionized water, and dry it with nitrogen; Micron-scale periodic groove structure;

[0038] (2) Use a magnetron sputtering apparatus to sputter a layer of ZnO seed crystal layer on the surface of the corroded galvanized engineering material for growing ZnO nanorods; the thickness of the seed crystal layer is controlled at about 10nm;

[0039] (3) Put the sample into the muffle furnace for annealing at 550℃ for 1h;

[0040](4) Soak the sample sputtered with a ZnO seed layer into a mixed solution of zinc acetate and hexamethylenetetramine, the ratio of the two substances is 0.5:1, and the concentration of zinc acetate is 0.01mol / L. In the case of 90 ℃ water bath reaction 2h. An array of nanoscale ZnO rods was grown.

[0041] (5) On the ZnO surface, a layer of l...

Embodiment 2

[0045] (1) Soak the white iron sheet of the galvanized engineering material in 1mol / L hydrogen ion sulfuric acid solution for 10 seconds, then take out the corroded galvanized engineering material, rinse it with deionized water, and dry it with nitrogen; this process grows micron The periodic gully structure of the level;

[0046] (2) Use a magnetron sputtering apparatus to sputter a layer of ZnO seed crystal layer on the surface of the corroded galvanized engineering material for growing ZnO nanorods; the thickness of zinc oxide is controlled at about 10nm;

[0047] (3) Put the sample into a muffle furnace for annealing at 200°C for 30 minutes;

[0048] (4) Soak the sample sputtered with a ZnO seed layer into a mixed solution of zinc acetate and hexamethylenetetramine, the ratio of the two substances is 2:1, and the concentration of zinc acetate is 0.2mol / L, reacted in a water bath at 50°C for 4h. An array of nanoscale ZnO rods was grown.

[0049] (5) A layer of low surfa...

Embodiment 3

[0053] (1) Soak galvanized engineering materials zinc and aluminum in 10mol / L hydrogen ion hydrochloric acid solution for 120 seconds, then take out the corroded galvanized engineering materials, rinse them repeatedly with deionized water, and dry them with nitrogen; this process A micron-scale periodic trench structure is grown;

[0054] (2) Zinc oxide seed layer prepared by liquid phase epitaxy: use spin coating technology to evenly spin coat 1-3% ethanol solution of amorphous zinc acetate at a speed of 3000rpm on the surface of the cleaned material, and in the muffle furnace The temperature was raised to 150°C for 10 minutes at a constant temperature, and then the temperature was raised to 325°C for 30 minutes at a constant temperature to obtain a relatively uniform zinc oxide seed layer; (The constant temperature reaction at high temperature in this step is the annealing process.)

[0055] (3) Soak the sample sputtered with a ZnO seed layer into a mixed solution of zinc ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

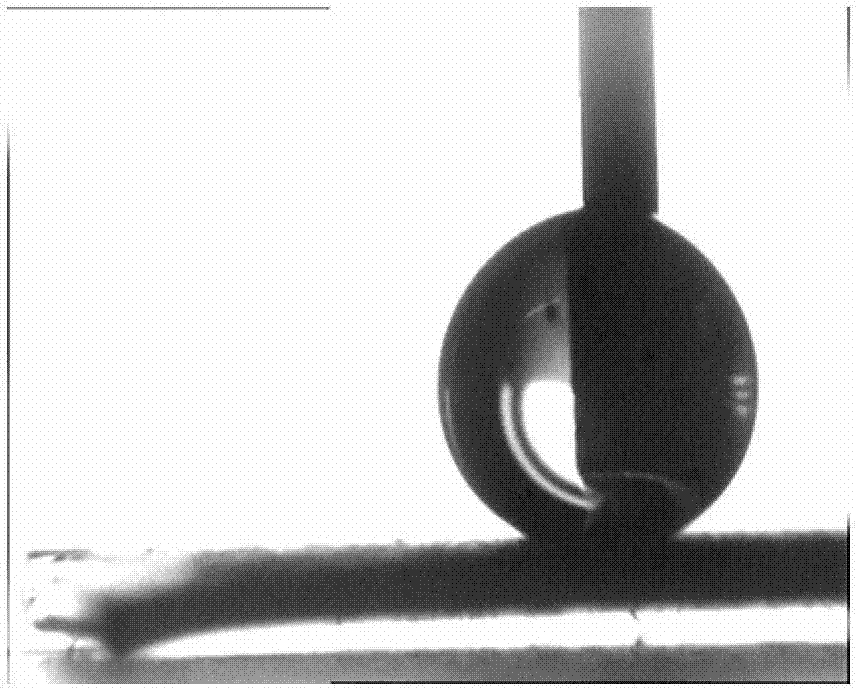

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com