Device and technology for loosening treatment on tobacco sheet bag

A tobacco sheet and processing equipment technology, applied in the fields of tobacco, cigarette manufacturing, transportation and packaging, etc., can solve the problems of poor working environment, low degree of automation, large crushing, etc. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings, but it is not limited to the embodiments.

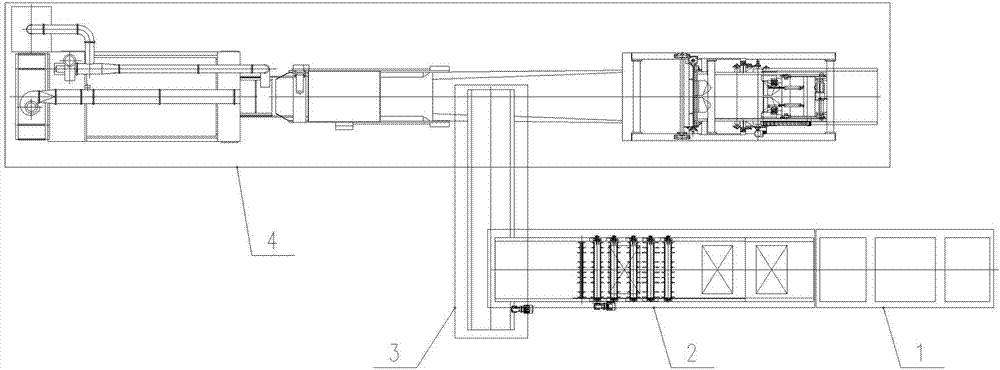

[0019] Such as figure 1 As shown, the box-opening unit 1, the thin cigarette pack loosening machine 2, and the material conveying and blending unit 3 of the present invention are connected in sequence and parallel to the processing section 4 of the flue-cured tobacco leaf of the existing tobacco factory. After the unpacked flake cigarette packs are completely loosened in the flake loosening machine 2, they are then directly blended with the flue-cured tobacco on-line through the material conveying blending unit 3.

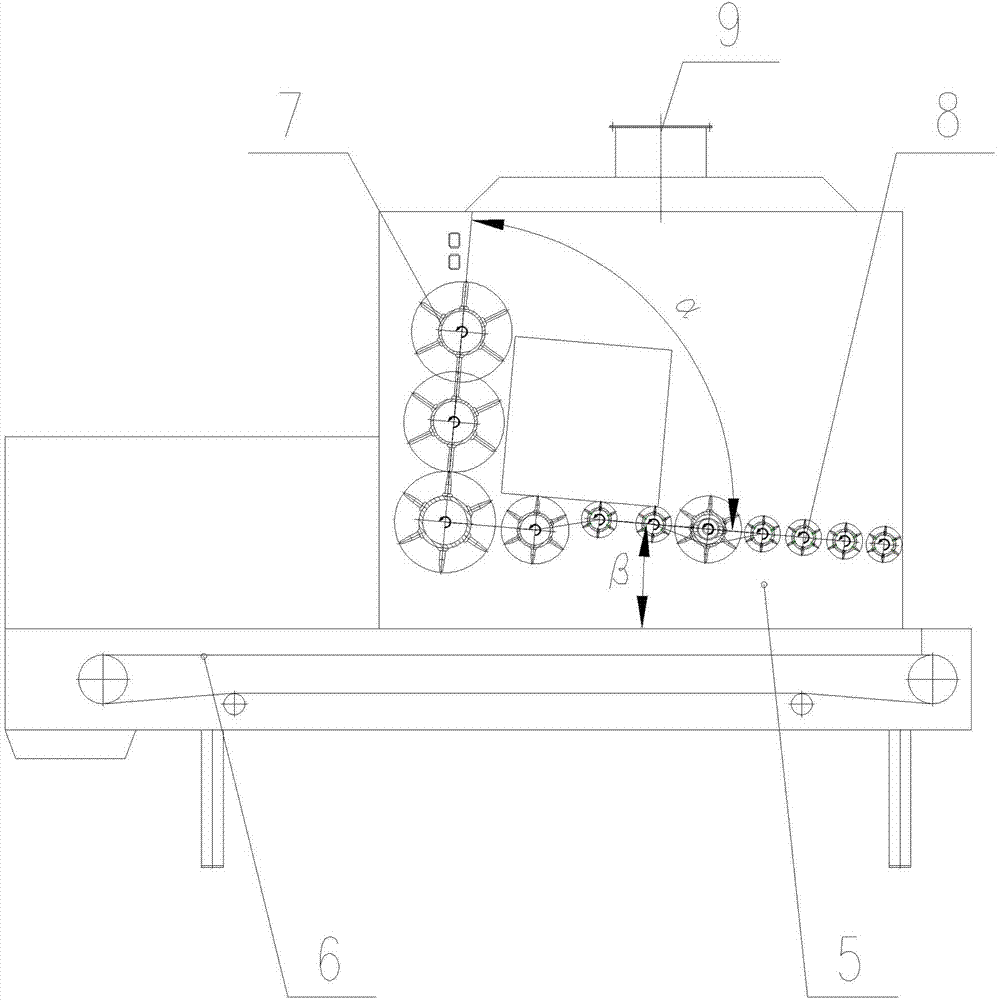

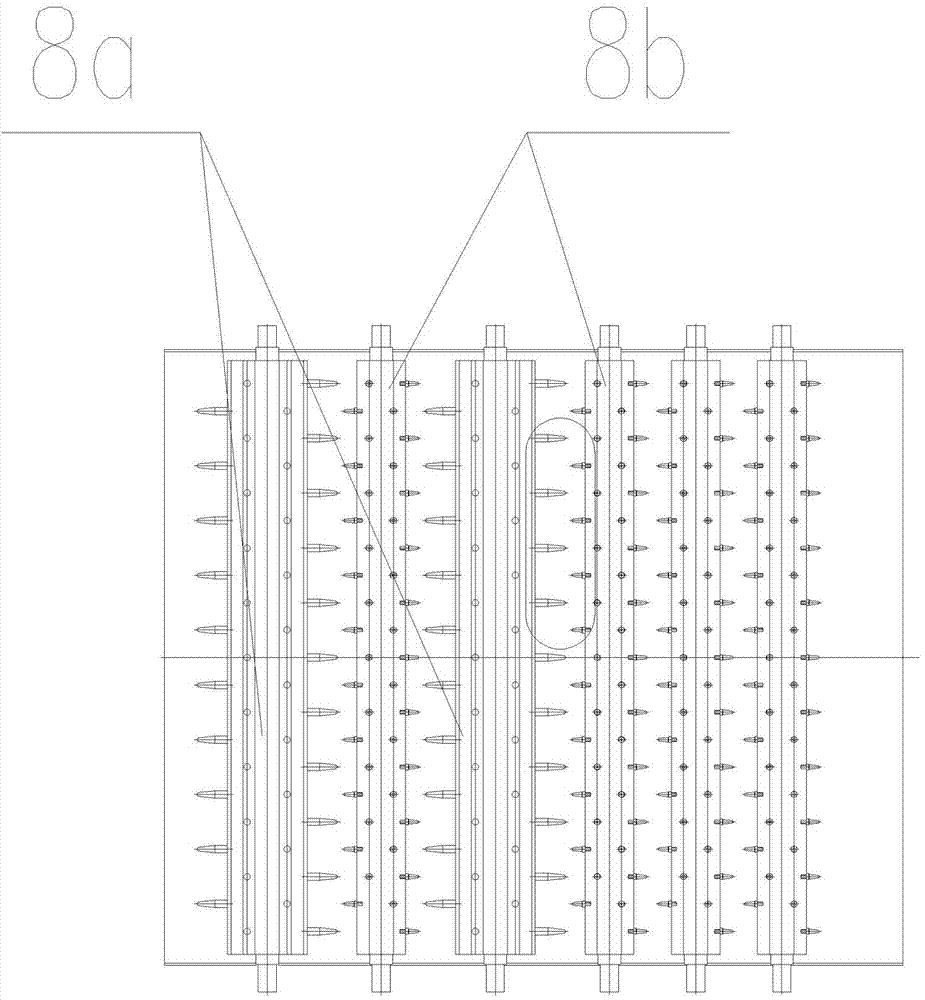

[0020] Such as figure 2 As shown, the sheet loosening machine of the present invention consists of a loosening device 5 and a conveyor 6 located below the loosening device; the loosening device 6 includes a vertical loosening roller 7 and a feeding loosening roller 8 installed on a frame The L-shaped loose roller assembly, the dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com