Improved process for recovering non-methane hydrocarbon in polyolefin tail gases by adsorption method

A technology for non-methane hydrocarbons and polyolefins, which is applied in the improvement field of the existing high-low pressure adsorption process for polyolefin tail gas, and can solve problems such as the failure of normal operation of the device and the difficulty in desorption of high-carbon hydrocarbons such as hexane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail through the examples of specific implementation methods below. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

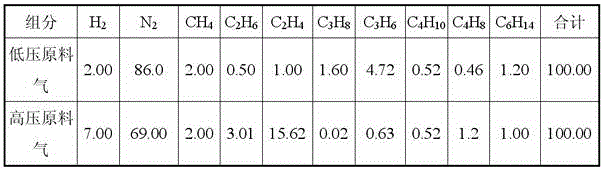

[0038] A factory's low-pressure polypropylene tail gas 2000Nm 3 / h, temperature 40°C, tail gas pressure 0.11MPa (absolute pressure), of which non-methane hydrocarbons 200 Nm 3 / h, high pressure polyethylene tail gas 1000Nm 3 / h, temperature 40°C, tail gas pressure 0.4MPa (absolute pressure), of which non-methane hydrocarbons 220 Nm 3 / h, the composition of the two exhaust gases is shown in Table 1:

[0039] Table 1 Composition of high and low pressure exhaust gas (V%)

[0040]

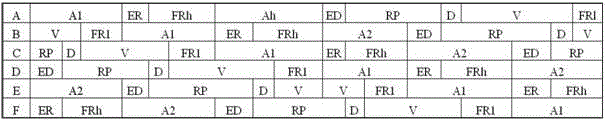

[0041] The pressure swing adsorption device for processing and recovering the above-mentioned polyolefin tail gas is composed of 6 adsorption towers, a set of buffer tanks and program-controlled valves. The adsorbents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com