Composite board of copper-foil-bonded ceramic substrate and preparation method of composite board

A ceramic substrate and composite board technology, applied in the field of composite boards, can solve problems such as waste of energy, cumbersome manufacturing process, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structure and preparation method of the composite panel of the present invention will be explained below in conjunction with examples.

[0039] refer to Figure 1 to Figure 5 Shown is the composite plate of copper foil bonded ceramic substrate of the present invention, its double-sided bonded copper foil, including ceramic substrate and copper foil, the ceramic substrate is made of aluminum oxide or aluminum nitride powder material, using a thin strip scraper Molding or powder compaction molding process The powder material is sintered into a ceramic substrate under atmospheric or oxygen-free high temperature (1900°C)1( figure 1 ), the preparation method of the composite board is as follows:

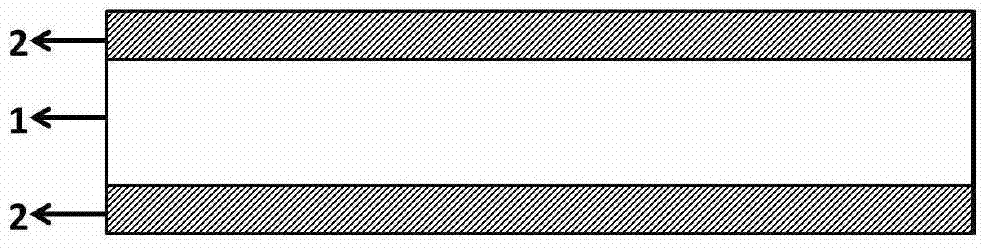

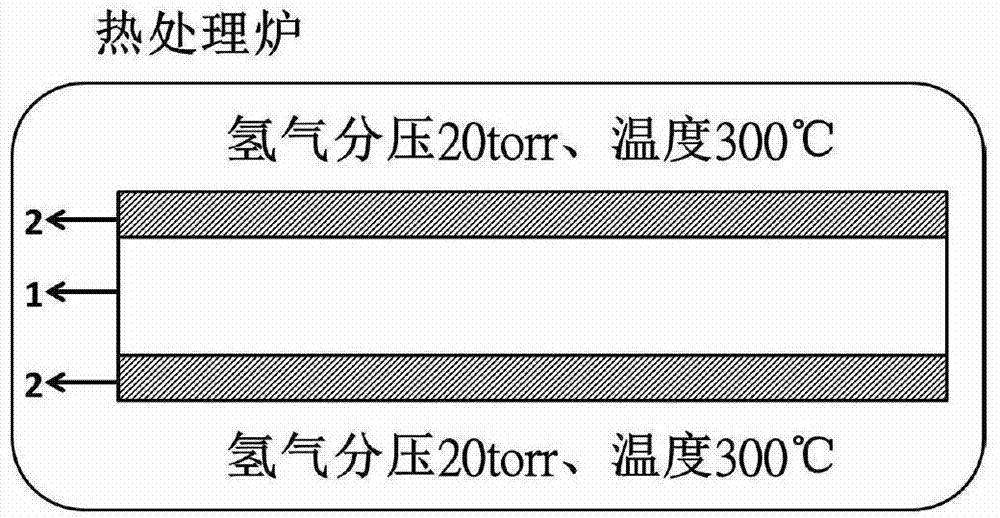

[0040] Step 1, the upper and lower surfaces of the ceramic substrate 1 are sputtered with a copper film 2 ( figure 2 ), to form a copper film with a thickness of less than 1 μm on the surface of the ceramic substrate, the operating temperature of the DC power sputtering mach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap