Heavy-duty truck cab suspension

A technology for heavy-duty trucks and suspension devices, which is applied to the superstructure, vehicle parts, transportation and packaging of trucks, can solve problems such as insufficient stability, poor comfort, and poor handling safety, achieve good ride comfort, improve Anti-bending ability, the effect of alleviating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiment is described in further detail below in conjunction with accompanying drawing:

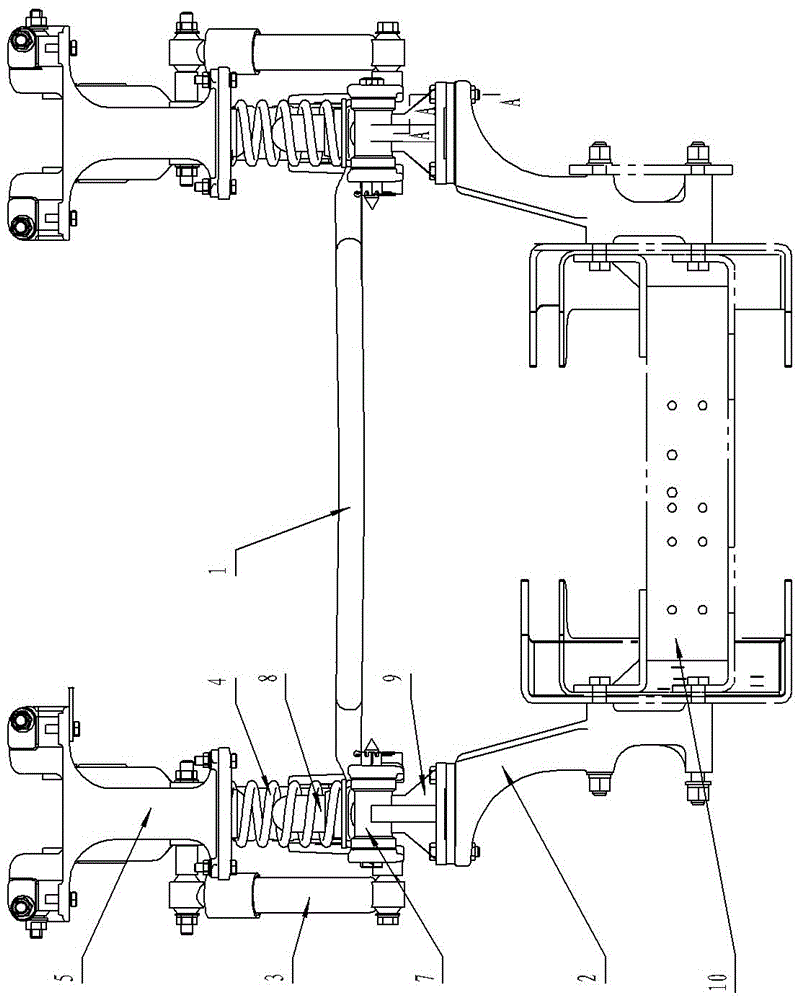

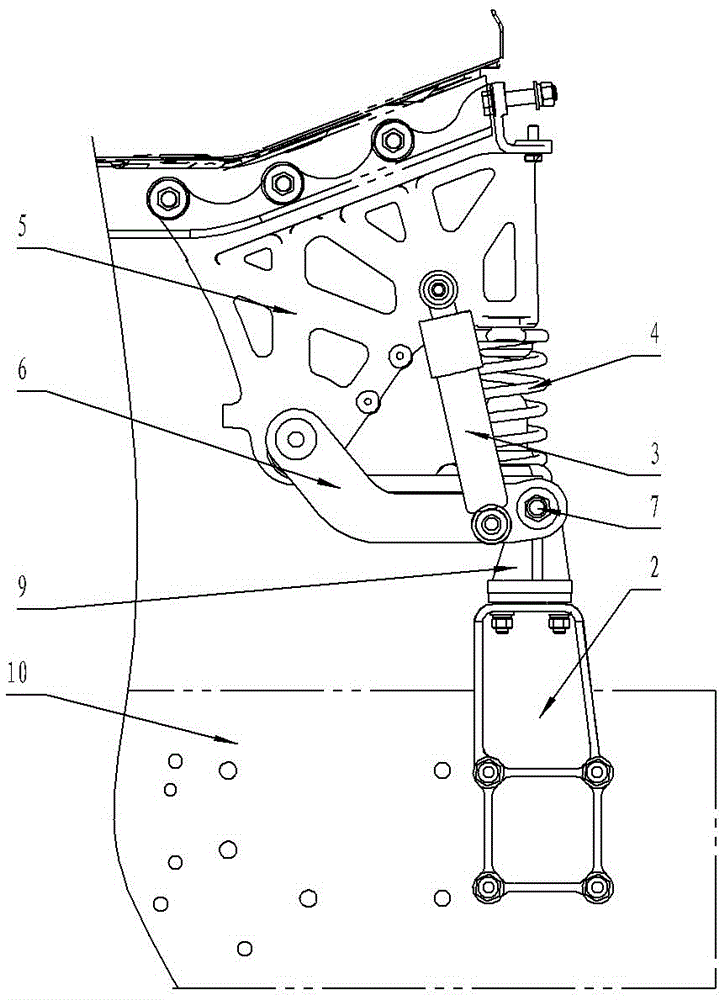

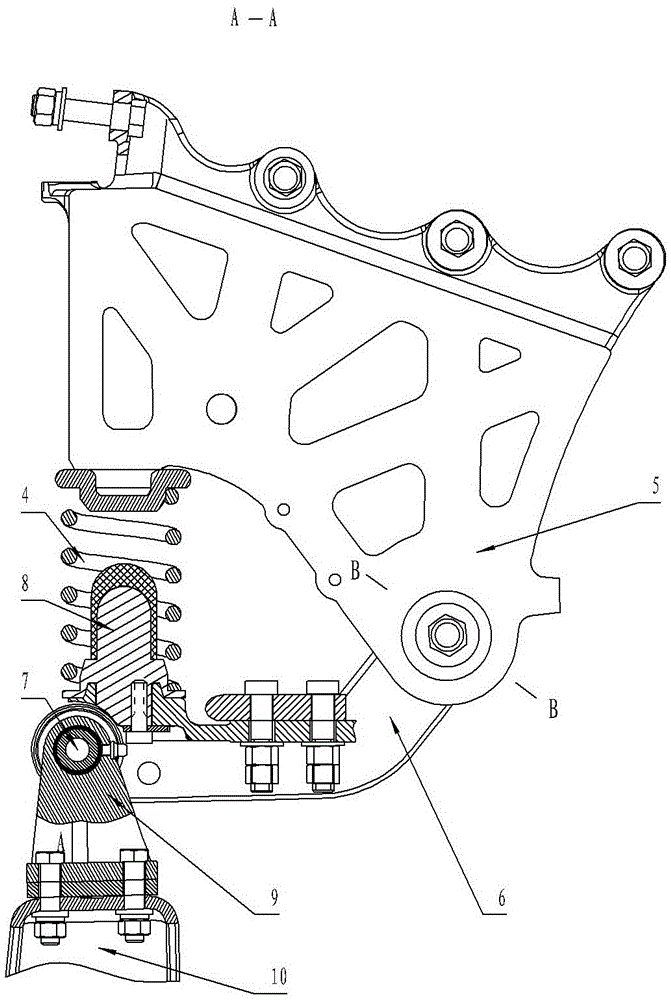

[0016] The present invention includes front suspension device and rear suspension device; Front suspension device such as figure 1 , figure 2 and image 3 As shown, it includes a front suspension stabilizer bar 1, a left suspension device and a right suspension device with the same structure installed at both ends of the front suspension stabilizer bar 1, and both of the left suspension device and the right suspension device include a front suspension upper support 5. The front suspension lower support 2, the front suspension shock absorber 3 and the coil spring 4; one end of the front suspension lower support 2 is fixedly connected with the vehicle frame 10, and the other end is connected with the front suspension turning shaft support 9, which is turned over at the front suspension The front suspension turning shaft 7 is installed on the shaft support 9, and the front suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com