Two-way memory alloy flow control device

A technology of flow control device and memory alloy, which is applied in transportation and packaging, air handling equipment, aircraft parts, etc. It can solve problems affecting the stable operation of working equipment, difficulty in starting working equipment, and fluctuations in ambient temperature, etc., and achieves light weight and structure. Simple, vibration-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

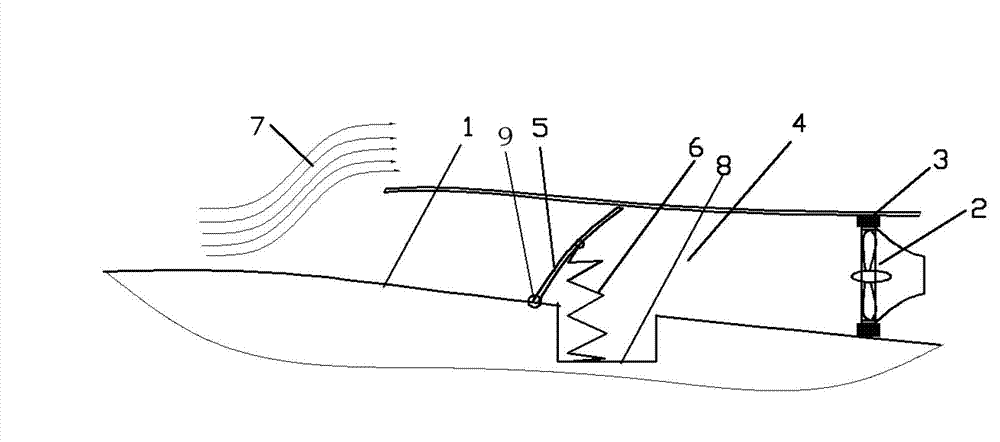

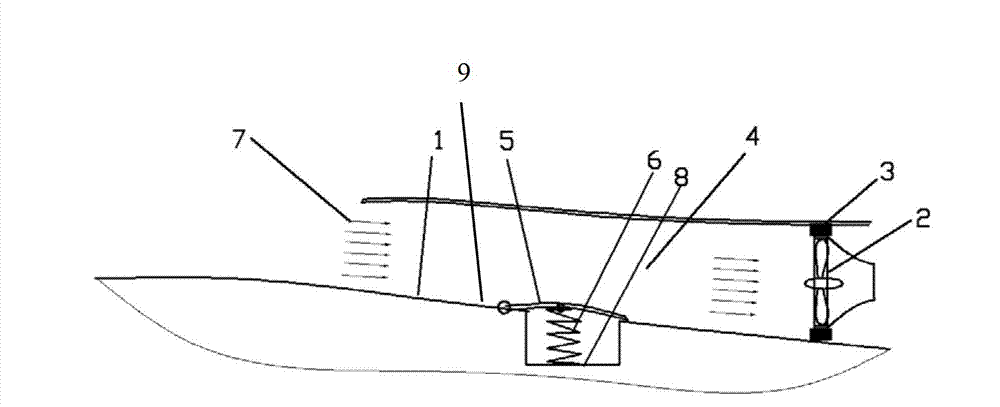

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

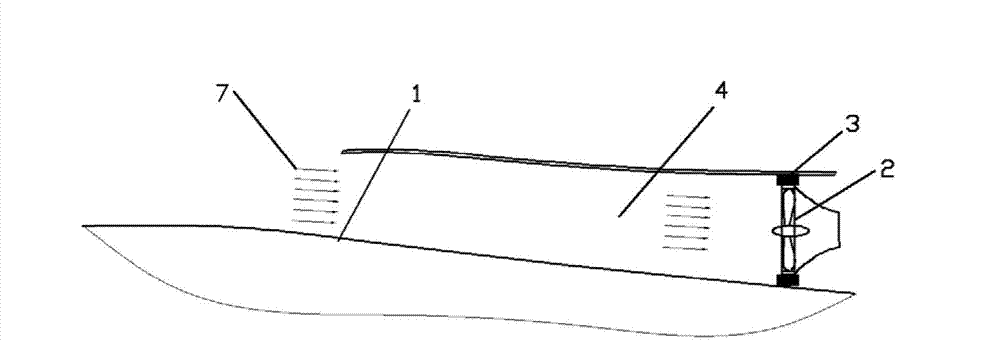

[0012] 1. The device includes a cooling air passage 4 installed on the outside of the aircraft body 1, working equipment 2 installed at the rear end of the cooling air passage 4, a shock-absorbing sealing bush 3, a flow control door 5 installed on the airframe, and a two-way memory alloy spring 6. Mounting groove 8,

[0013] The cooling air channel 4 described in 2 is a common general air intake on existing aircraft, and the active air device 2 is arranged at the rear end of the cooling air channel 4, and the flexible installation bushing 3 is connected around the air device 2, which can slow down With the vibration of the wind equipment, the outer side of the installation bush is closely connected with the inner wall of the air inlet.

[0014] 3. There is a memory alloy installation groove 8 on the aircraft body. The installation groove 8 is located at the far end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com