Modified cloth swing mechanism

A crank rocker mechanism and fabric guide roller technology, which is applied in the directions of folding thin materials, thin material handling, transportation and packaging, etc., can solve problems such as insufficient swing width, high cloth pile, inconvenient transit transportation and normal production management, etc., to achieve Improve the degree of automation and simplify the effect of the arrangement mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

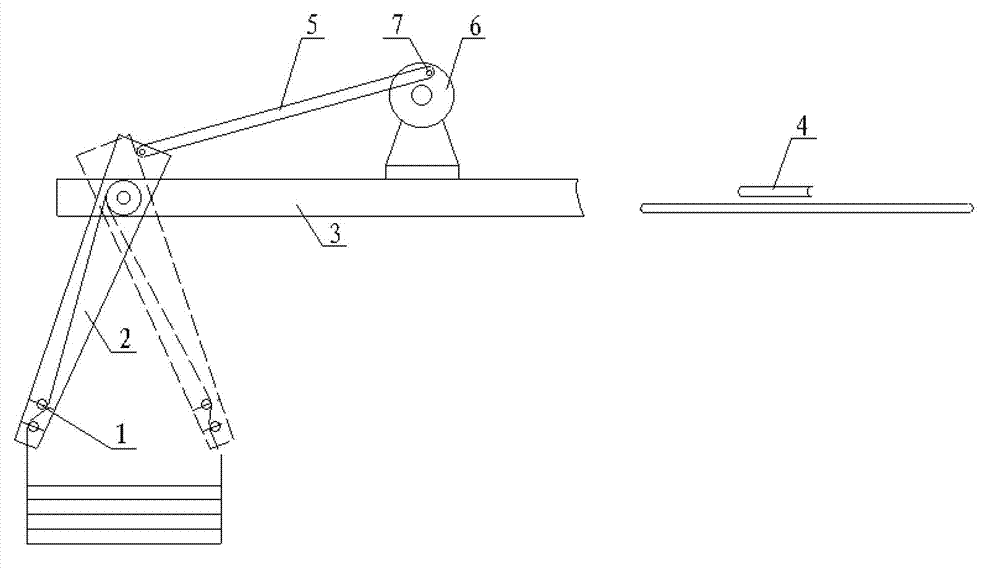

[0008] In the original design, the fabric passes through the rotating traction roller 4, then passes through two small fabric guide rollers 1, and is output by the swing arm 2. The swing of the swing arm 2 is transmitted by the power on the traction roller 4 through a chain drive. As a result, the swing of swing arm 2 is too small and difficult to adjust. Such as figure 1 An improved arrangement mechanism shown includes a beam 3, a swing arm 2 and a cloth guide roller 1. The beam 3 is provided with a miniature reduction motor 6, and the miniature reduction motor 6 is controlled by a frequency converter. The miniature reduction motor A crank 7 is installed on the motor 6, the crank 7 is hinged with the connecting rod 4, the connecting rod 4 is hinged with the swing arm 2, and the swing arm 2 is hinged with the crossbeam 3 to form a crank rocker mechanism.

[0009] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com