Catalyst for block polyether synthesis and application thereof

A block polyether and catalyst technology, applied in the application field of block polyether synthesis, can solve the problem of wide molecular weight distribution of block polyether

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

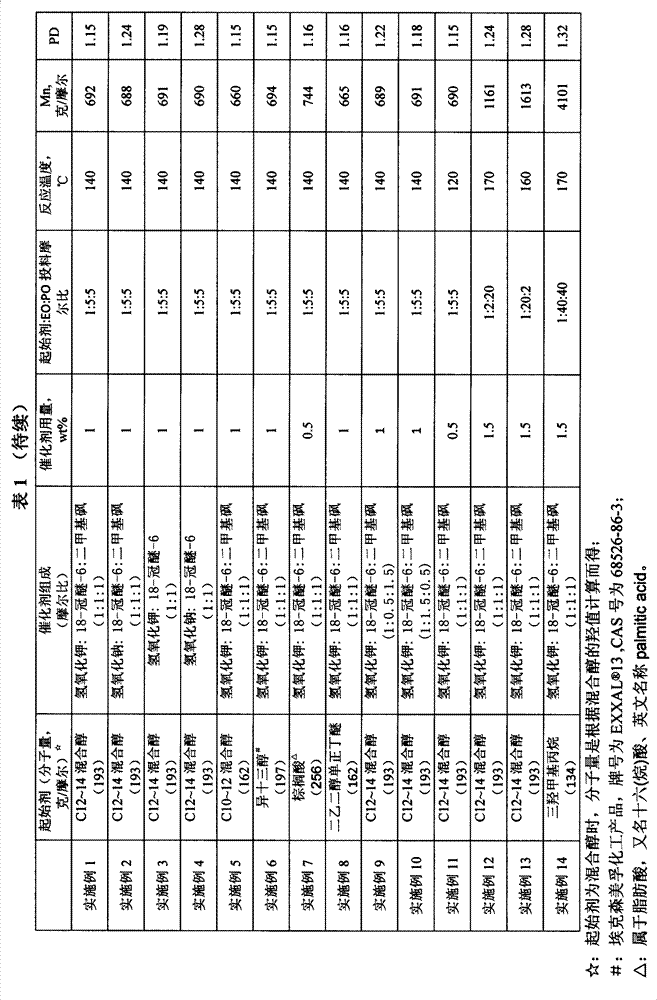

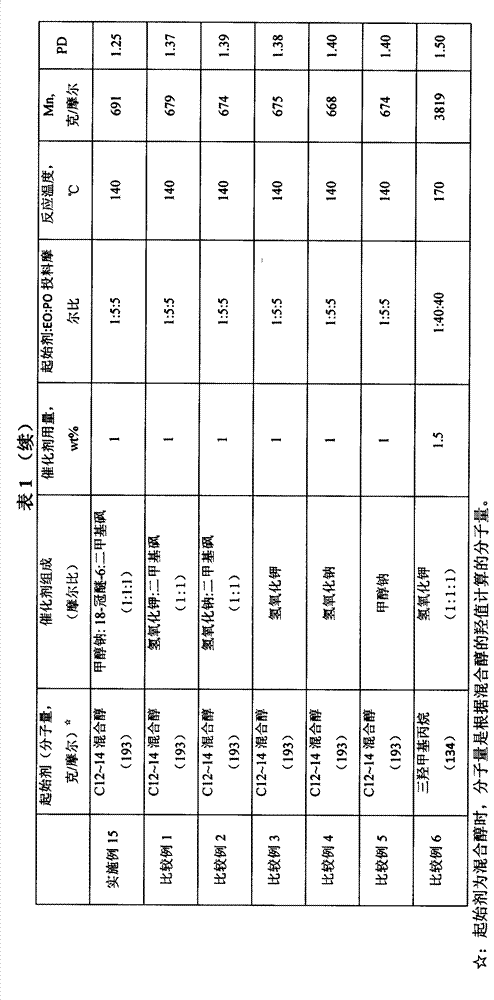

Examples

Embodiment 1

[0025] Charge C into a 2L reactor with stirring, electric heating jacket, and internal water cooling coil 12~14 Mix alcohol 386g, 14.1 grams of catalysts, and seal the reaction kettle. Replace the atmosphere in the reactor with nitrogen for three times, start stirring, heat up to 80°C and carry out vacuum treatment under the pressure of -0.09MPa for 60min, then raise the temperature to 140°C and maintain this temperature, slowly pass in ethylene oxide, pass Control the feeding speed of ethylene oxide to keep the reaction pressure at 0.2MPa, stop the feeding after feeding a total of 441 grams of ethylene oxide, and carry out the aging reaction at 140°C for 3 hours; then heat up to 140°C and maintain this temperature, Slowly feed propylene oxide, keep the reaction pressure at 0.2MPa by controlling the feeding speed of propylene oxide, stop feeding after feeding a total of 581g of propylene oxide, carry out the aging reaction at 140°C for 3 hours, and lower the temperature to 60...

Embodiment 2

[0028] Charge C into a 2L reactor with stirring, electric heating jacket, and internal water cooling coil 12~14Mix alcohol 386g, 14.1 grams of catalysts, and seal the reaction kettle. Replace the atmosphere in the reactor with nitrogen for three times, start stirring, heat up to 80°C and carry out vacuum treatment under the pressure of -0.09MPa for 60min, then raise the temperature to 140°C and maintain this temperature, slowly pass in ethylene oxide, pass Control the feeding speed of ethylene oxide to keep the reaction pressure at 0.2MPa, stop the feeding after feeding a total of 441 grams of ethylene oxide, and carry out the aging reaction at 140°C for 3 hours; then heat up to 140°C and maintain this temperature, Slowly feed propylene oxide, keep the reaction pressure at 0.2MPa by controlling the feeding speed of propylene oxide, stop feeding after feeding a total of 581g of propylene oxide, carry out the aging reaction at 140°C for 3 hours, and lower the temperature to 60°...

Embodiment 3

[0031] Charge C into a 2L reactor with stirring, electric heating jacket, and internal water cooling coil 12~14 Mix alcohol 386g, 14.1 grams of catalysts, and seal the reaction kettle. Replace the atmosphere in the reactor with nitrogen for three times, start stirring, heat up to 80°C and carry out vacuum treatment under the pressure of -0.09MPa for 60min, then raise the temperature to 140°C and maintain this temperature, slowly pass in ethylene oxide, pass Control the feeding speed of ethylene oxide to keep the reaction pressure at 0.2MPa, stop the feeding after feeding a total of 441 grams of ethylene oxide, and carry out the aging reaction at 140°C for 3 hours; then heat up to 140°C and maintain this temperature, Slowly feed propylene oxide, keep the reaction pressure at 0.2MPa by controlling the feeding speed of propylene oxide, stop feeding after feeding a total of 581g of propylene oxide, carry out the aging reaction at 140°C for 3 hours, and lower the temperature to 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com