Circular knitting machine density regulating device with inductive alarm mechanism

A technology of induction alarm and density, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of complex structure of induction alarm mechanism, economic loss of consumers, troublesome maintenance, etc., to achieve convenient control and economical application, reduce maintenance Cost and labor cost, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

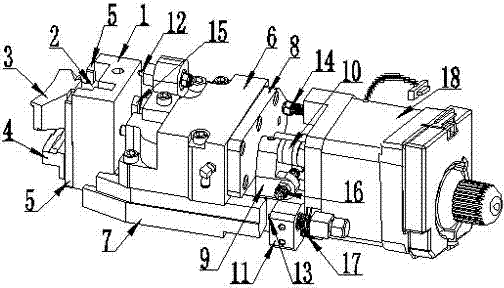

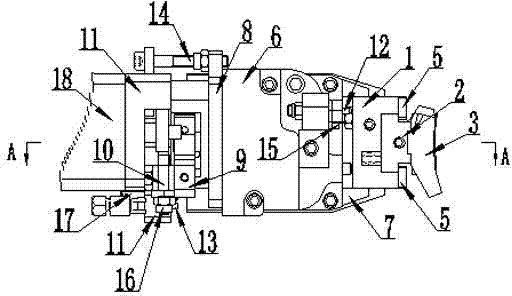

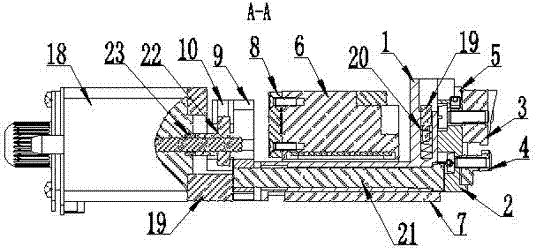

[0031] See attached picture. This embodiment is composed of a driving mechanism, a transmission mechanism, a dynamic density transmission mechanism and a piston mechanism. The driving mechanism is transmitted to the transmission mechanism, thereby driving the dynamic density transmission mechanism connected with the transmission mechanism to move, thereby completing the program instructions. The transmission mechanism includes a triangular base 7 with a transverse installation hole on the triangular base 7 , a transmission rod 21 in the installation hole, and a density cam 28 fixedly installed at one end of the transmission rod 21 .

[0032] The dynamic density transmission mechanism includes a dynamic density triangle base 1 , a dynamic density triangle slider 2 , a dynamic density needle pressing cam 3 , and a dynamic density needle lifting cam 4 . The dynamic density pressing cam 3 includes a needle trajectory surface 31, which is formed by connecting the first needle traj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com